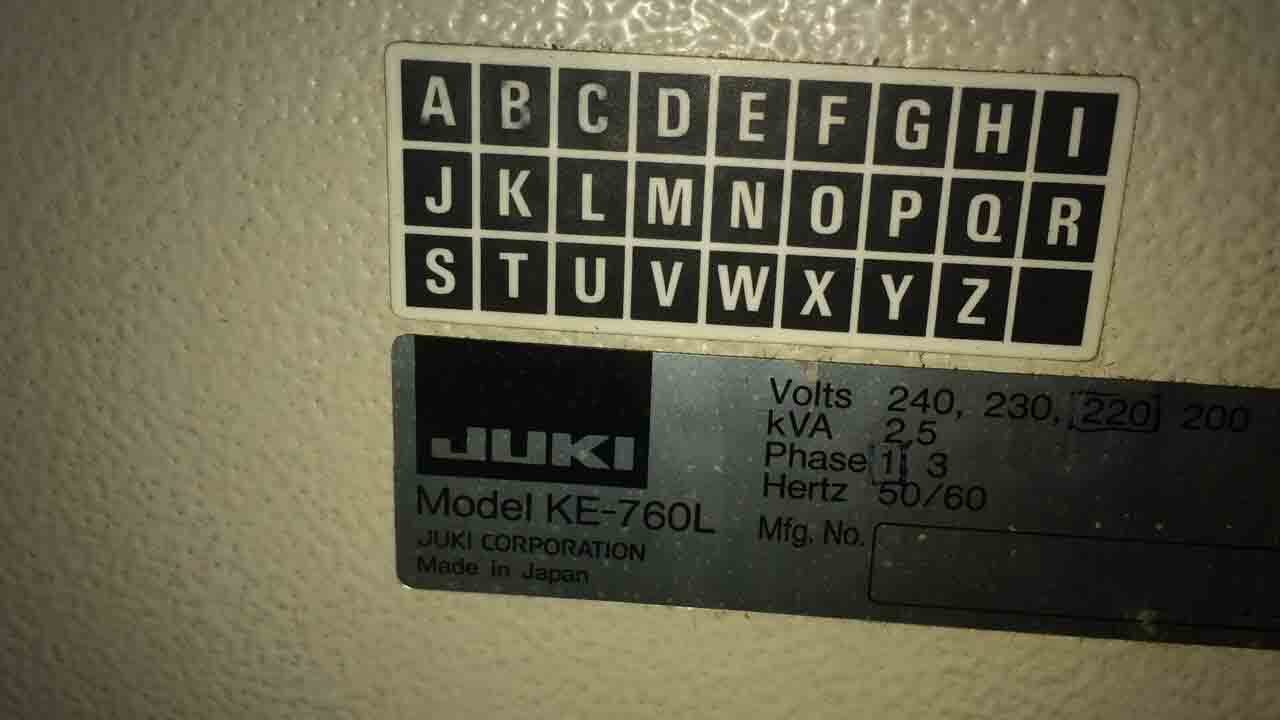

Used ZEVATECH / JUKI KE 760L #9399521 for sale

URL successfully copied!

Tap to zoom

ZEVATECH / JUKI KE 760L is a powerful and versatile pc board assembly and manufacturing equipment designed to help maximize production speed and quality. It utilizes a 12,000 placements per hour (pph) speed for component placement and is capable of handling components up to 45mm in size. It is equipped with a rail-mounted vibratory feeders to facilitate component feed capability. The feeder configuration also allows for component pre-tape loading. JUKI KE 760L is equipped with a 4-axis board tracking system and is capable of handling boards of up to 13" x 13" in size. It additionally has 2 flexible component magazines and is capable of accommodating a combined total of 32 component sizes. In terms of component placement accuracy, the unit utilizes an advanced high-end vision machine that enables component placement accuracy as fine as 0.020". This is made possible by the use of a combination of advanced optical and motion technologies, as well as offline components calibration to help ensure repeatability. This accuracy also helps to minimize component costs, as well as reduce machine set-up time. In terms of connectivity and control, the tool utilizes a revolutionary X-Y generation controller architecture to enable fast response time and support a variety of different applications. Additionally, ZEVATECH KE760L is equipped with an optional PC-based control technology for PC boards components to enable easy communication with application programs. In terms of data management and program editing capabilities, the asset utilizes an intuitive touch screen that allows the user to easily track and adjust assembly programs. The touch screen also provides access to the model's comprehensive help menu and operator's manual. Finally, the equipment also features a comprehensive service menu to assist with troubleshooting and maintenance of the system. In summary, ZEVATECH KE 760L is a powerful and versatile pc board assembly and manufacturing unit designed to maximize production speed, accuracy and quality. It features 12,000 placements per hour (pph) speed, rail-mounted vibratory feeders, 4-axis board tracking machine, 2 flexible component magazines, advanced vision tool for component placement accuracy, X-Y generation controller architecture for fast response time, PC-based control technology for PC boards components, intuitive touch screen for data management and program editing, and a comprehensive service menu for troubleshooting.

There are no reviews yet