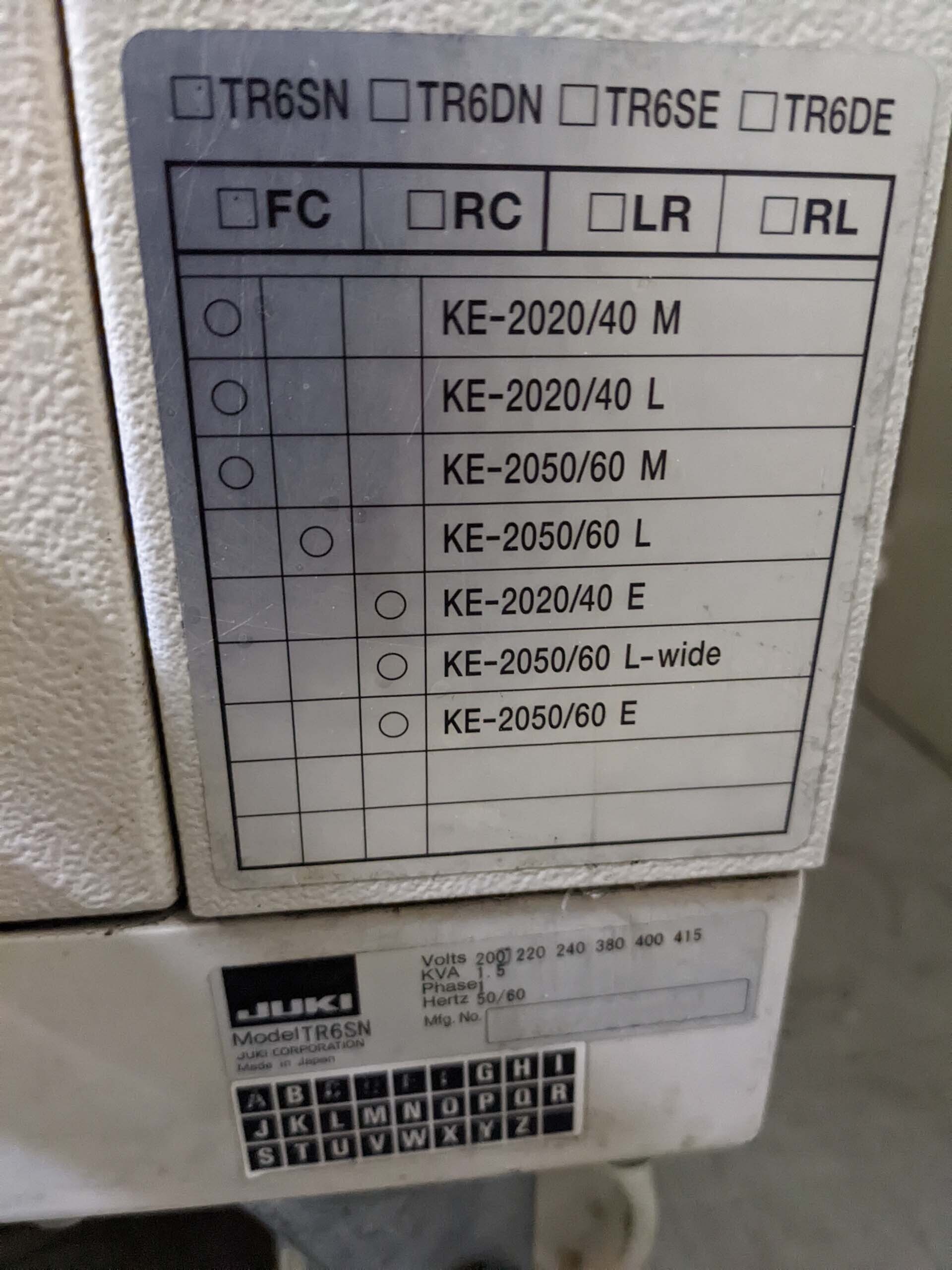

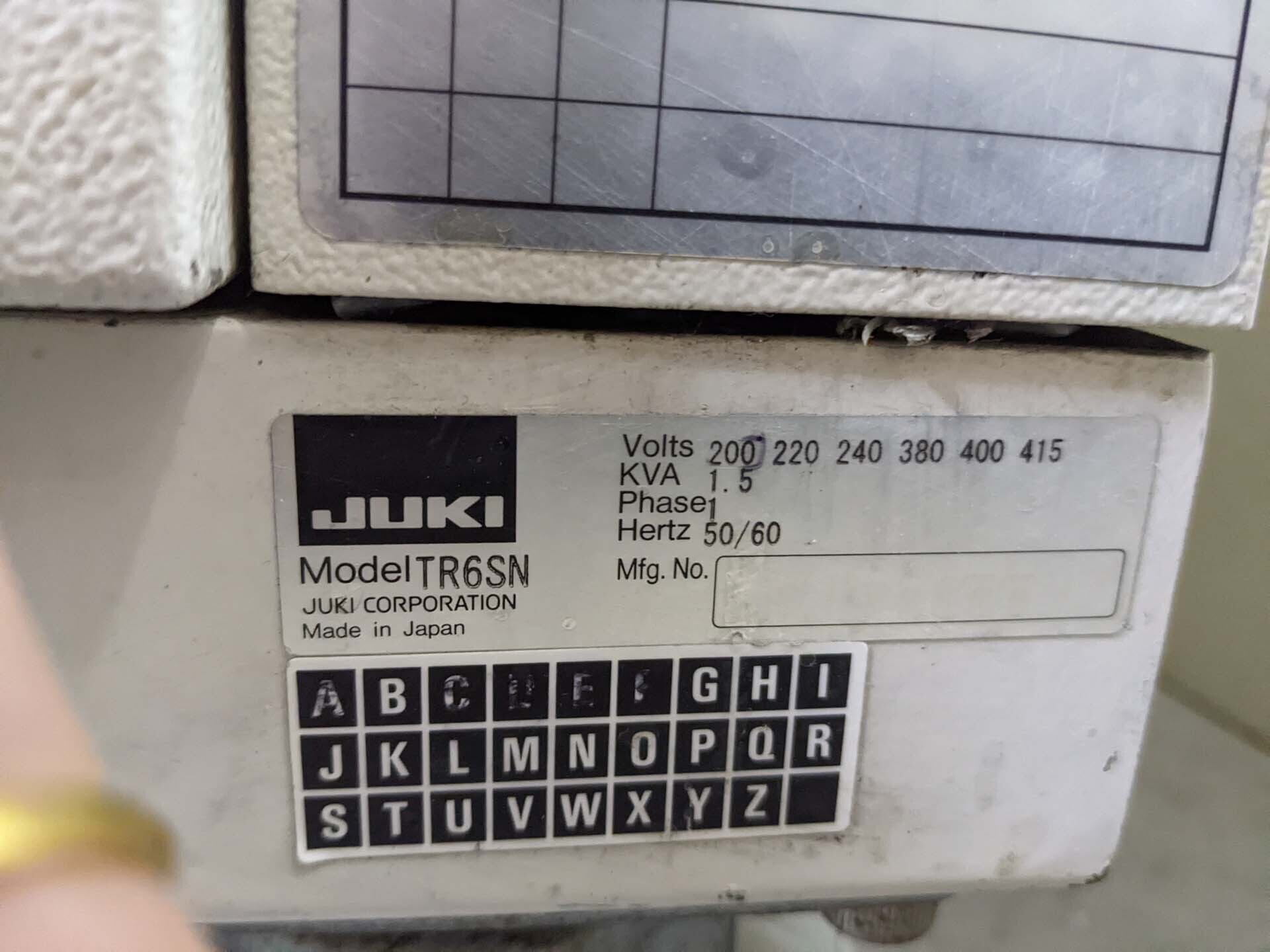

Used ZEVATECH / JUKI TR-6SN #293610256 for sale

URL successfully copied!

Tap to zoom

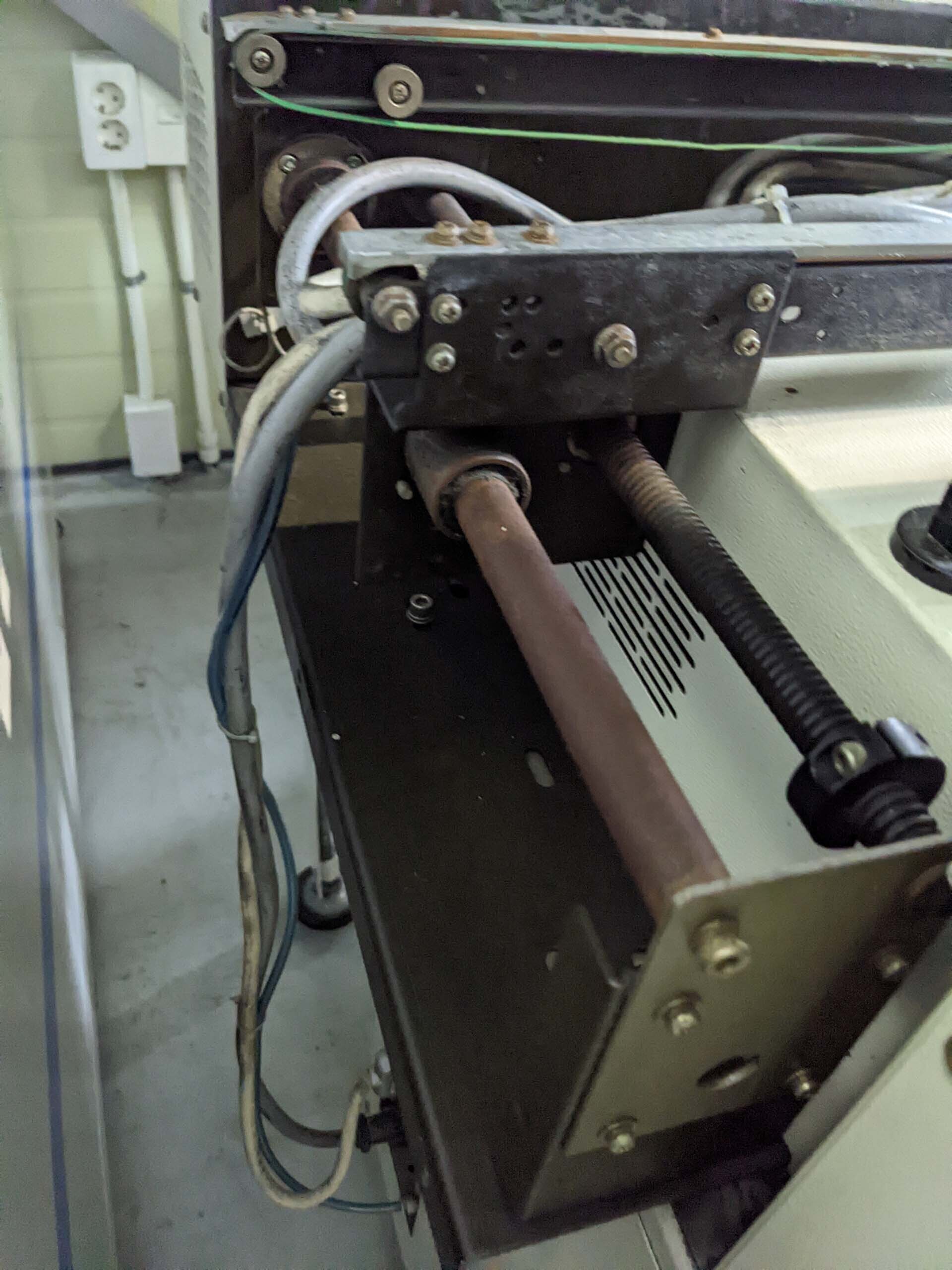

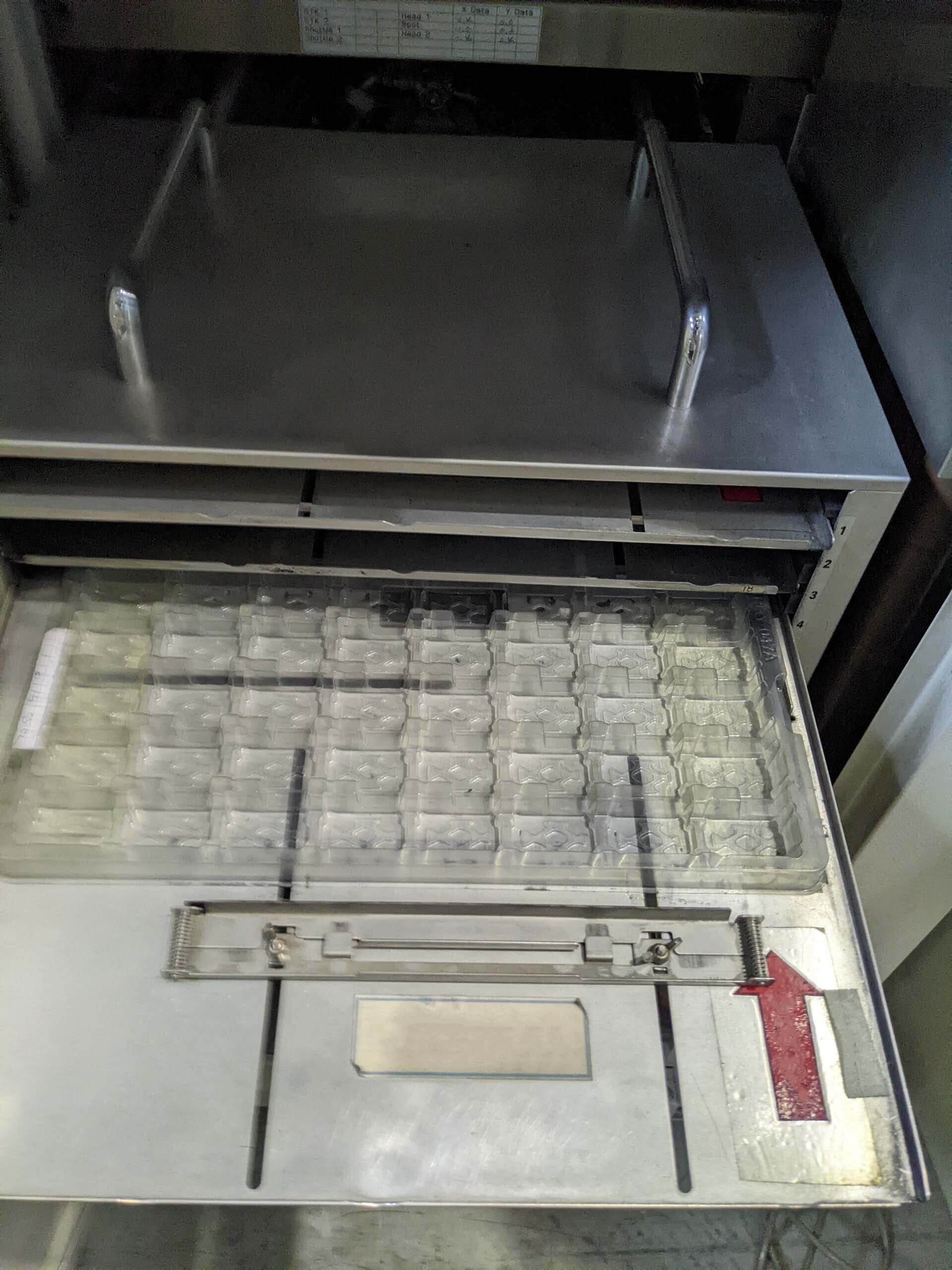

ZEVATECH / JUKI TR-6SN is a high-performance low-cost PCB assembly and manufacturing equipment from JUKI. It is designed to be easy to use with high accuracy, speed, and reliability. It utilizes a 16-point SMT pick-and-place head for high-accuracy placement of components, with a maximum speed of 200 placements per minute. The system also features a 3-axis high-speed servo unit that provides the high-speed motion necessary for PCB assembly. The machine utilizes a proprietary closed-loop camera inspection tool, providing error-free inspection of components prior to placement. This ensures that any incorrect placements are quickly avoided, leading to better yield and improved quality. The asset also includes a host of features such as board size detection, component shape recognition, and integrated error prevention mechanisms. The user interface provides easy-to-use functions such as automatic feeder adjustment and teaching, with intuitive operation and real-time instructions. The model also has several specialized tools for more complex components and assemblies. These include rotary and shuttling tools for more precise placement of components, as well as a rotary jetting tool for application of solder paste to specific areas of the PCB. The equipment is highly customizable, allowing for user-defined settings such as placement speed and programmable parameters. It is also capable of working with a wide range of materials and components, from 0201 size components to larger BGAs. Overall, JUKI TR-6SN is an excellent choice for PCB assembly and manufacturing. It features a wide range of features and capabilities, and comes at an affordable price. With its advanced closed-loop camera inspection system, high accuracy, and versatile tools, it is perfect for a wide range of assembly needs.

There are no reviews yet