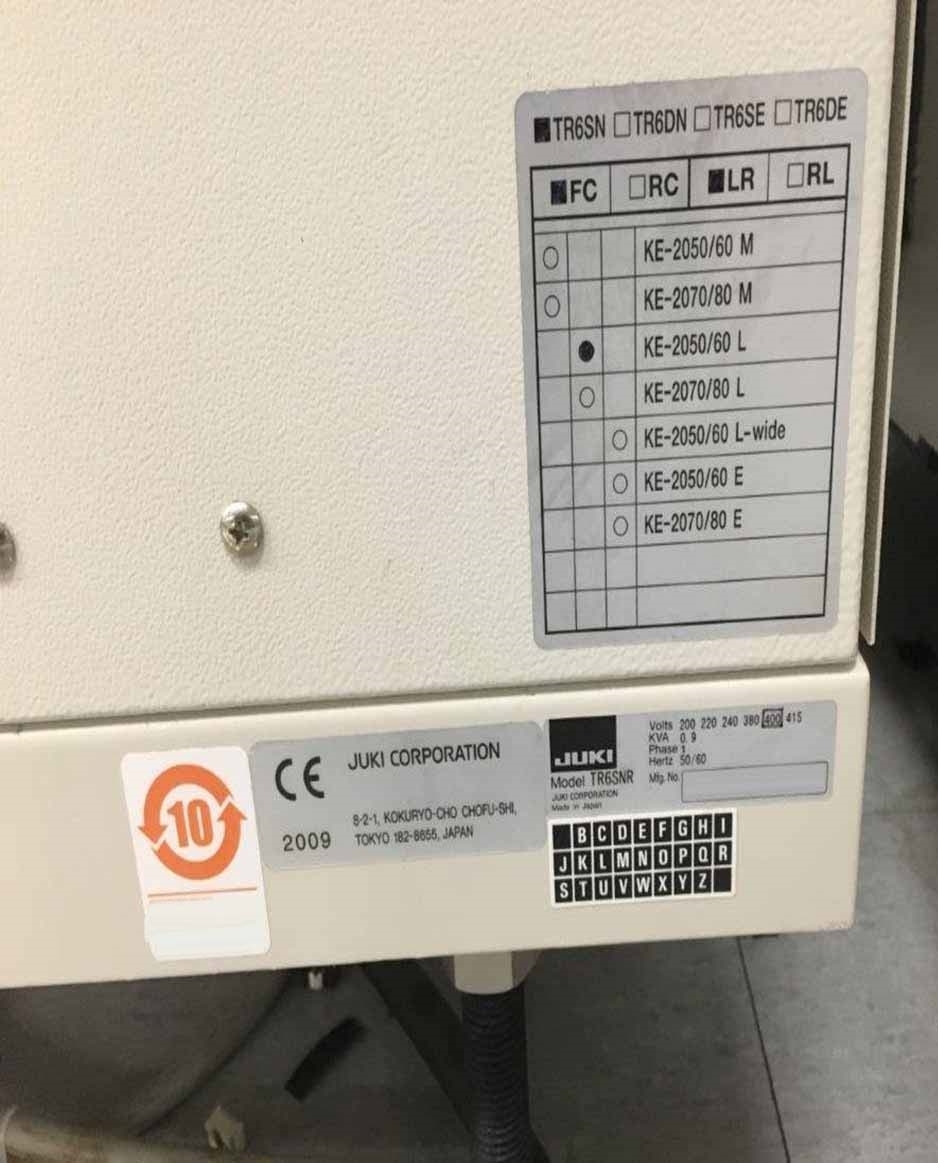

Used ZEVATECH / JUKI TR 6SNR #9254057 for sale

URL successfully copied!

Tap to zoom

ID: 9254057

Vintage: 2009

Tray changer

(2) Small and large types of suction pads

Feeding components: 5 mm (Suction surface) to 50 mm (dimension)

Delay timer

Air:

Pressure: 0.5±0.05 Mpa

Consumption: 50 L/min (ANR)

Atmospheric dew point - 17°C / Lower (Dry air) environmental condition

Ambient temperature:

Under operation: +10°C to +35°C

On transport / Storage: -15°C to +70°C

Humidity:

Under operation: 50%RH (35°C), 90%RH (20°C)

On transport / Storage: 20% to 95%RH (No condensation allowed)

Printed board:

Board size:

Minimum: (X) 50mm x (Y) 30mm

Maximum: (X) 410mm x (Y) 360mm

Board thickness: 0.4mm to 4.0mm

Board warp limit (free state):

Maximum upward: 2 mm

Maximum downward size: 4mm

Power Supply: 200 VAC, 900 VA, 50/60 Hz

2009 vintage.

ZEVATECH / JUKI TR 6SNR is a PC board assembly and manufacturing equipment. The system is designed to deliver fast and efficient components assembly, making it perfect for a variety of applications. It allows for quick replacement and setup of all components and sub-assemblies, and allows users to quickly and accurately assemble PC boards. The unit is equipped with features such as a 3-axis direct drive, high-speed vision recognition, microprocessor-controlled robot, motion control board, and a comprehensive suite of software tools. The direct drive technology allows for more precise and fast motion control while the robot provides smooth and accurate placement. The motion control board allows users to set up repeatable patterns for product assembly speed. The computer software tools are programs designed to make the design, assembly, and testing of the product easier. JUKI TR 6SNR exhibits high accuracy, speed, and high-quality construction. It achieves a placement speed of over 22,500 components per hour and accuracy of 0.10mm in placement. Adopting a nozzle-mounted nozzle changer saves the time of manual setup. Its Vision Recognition machine also offers high placement accuracy for parts of any shape. ZEVATECH TR 6SNR is designed for long-term reliability, making it a perfect choice for those planning on using it for high-volume work. In terms of safety features, TR 6SNR is designed to keep operators and bystanders safe. It does this by limiting access to only authorised personnel, and it has a secure circuit board to prevent electrical shock. It also features an ergonomic design for comfortable operation. ZEVATECH / JUKI TR 6SNR is a reliable PC board assembly and manufacturing tool that is designed for fast, efficient, and accurate assembly of components. Its suite of software tools, robot placement, motion control board, and high-speed vision recognition technology makes it perfect for high-volume, precision-focused projects. Its safety features and ergonomic design help ensure the safety of its users, making it the perfect choice for those in need of quality, repeatable assembly.

There are no reviews yet