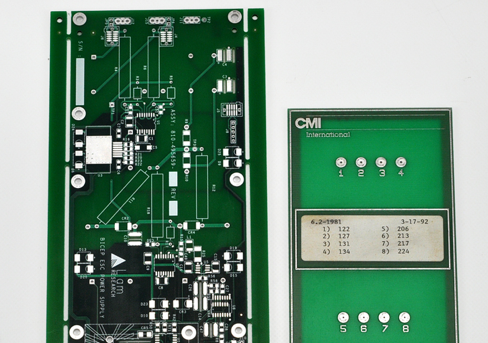

Used CMI / OXFORD MFX #167018 for sale

URL successfully copied!

Tap to zoom

ID: 167018

Combination system

Measure methods: microresistance, eddy current/magnetic induction/nickel over nonmagnetic, and beta backscatter

Used to test electronic boards

Configuration:

CMI MFX controller with manual

Thickness gauge head unit

Thermal printer

CMI MFX controller, P/N: 200220:

Probe ports: BMX, MRX, EMX

RS-232 Interface

Parallel Printer port

Footswitch port (footswitch not included)

VAC: 90-230

Hz: 50-60

TRP-1A/S thickness gauge head unit, P/N: 200955

Display port: 25 pin

Cables included: controller power cable, thickness guage power cable, printer ac adaptor, printer cable, display cable.

CMI / OXFORD MFX is a PC board inspection equipment, specifically designed to provide precise, non-contact inspection and measurement of printed circuit boards (PCBs). Built on a highly reliable, fast, accurate and flexible platform, this state-of-the-art machine runs significantly faster than other similar systems. With automated feature recognition capabilities, it requires minimal setup and training to quickly become up-and-running. At its core, CMI MFX is equipped with a XP6 vision inspection system with a resolution of 380 x 270 nm. This optical precision greatly improves the accuracy of the measurements, producing more consistent results when measuring electronic components and enabling repeatable performance. The unit also features a 6-axis motion controller and an adaptable stage, allowing for precise and complex movements and maximum flexibility within the production environment. OXFORD MFX has the ability to rapidly inspect and measure a wide range of PCBs. It can be used to measure the placement, location and size of components, as well as any misalignment and other imperfections. In addition, the machine is capable of recognizing and measuring circuits, solder joints (especially BGA's) and functionalities with optical recognition techniques. MFX is designed with user-friendly, intuitive software. The integration of this software helps to significantly reduce the setup time, facilitate set-up and enable repeatable performance. By automating processes and reducing the complexity of the tool, it allows the user to focus solely on their job and not the technical side of the inspection process. Furthermore, CMI / OXFORD MFX is offered with fully packaged software and automated inspection reports, enabling efficient tracking and recording of results. CMI MFX is built with a range of configurable options to customize performance to a given application. According to customer needs, the asset can be outfitted with additional hardware, such as high resolution linear stages, x-y tables and additional software features. Whatever the specification of OXFORD MFX, its features are designed to help achieve reliable, repeatable and accurate performance and to reduce process times. In conclusion, MFX is a powerful, highly-precise and reliable inspection and measurements model, with automated features and a streamlined design to help reduce setup and process times. Its features are designed to make the inspection of PCBs faster, more accurate and more efficient.

There are no reviews yet