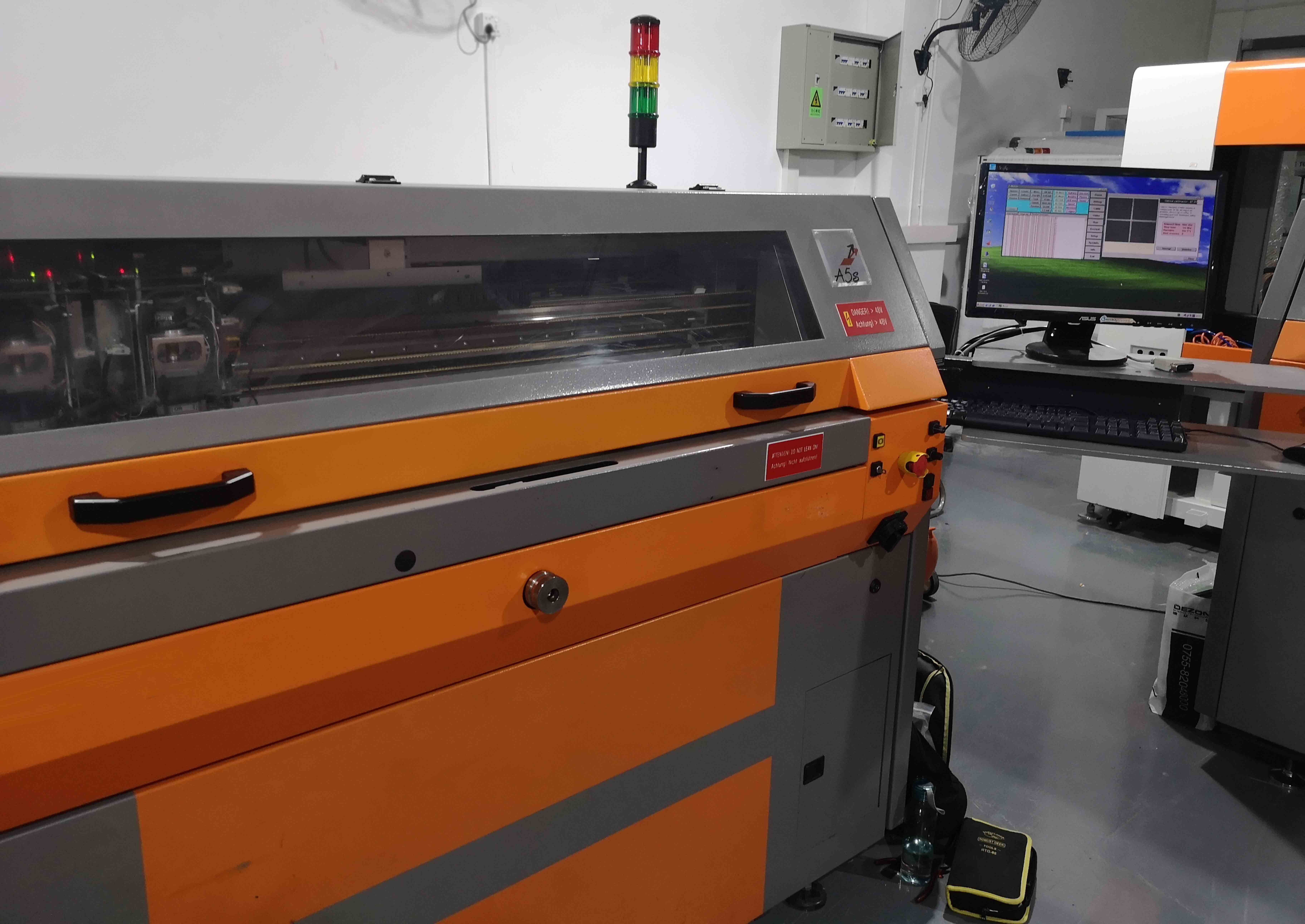

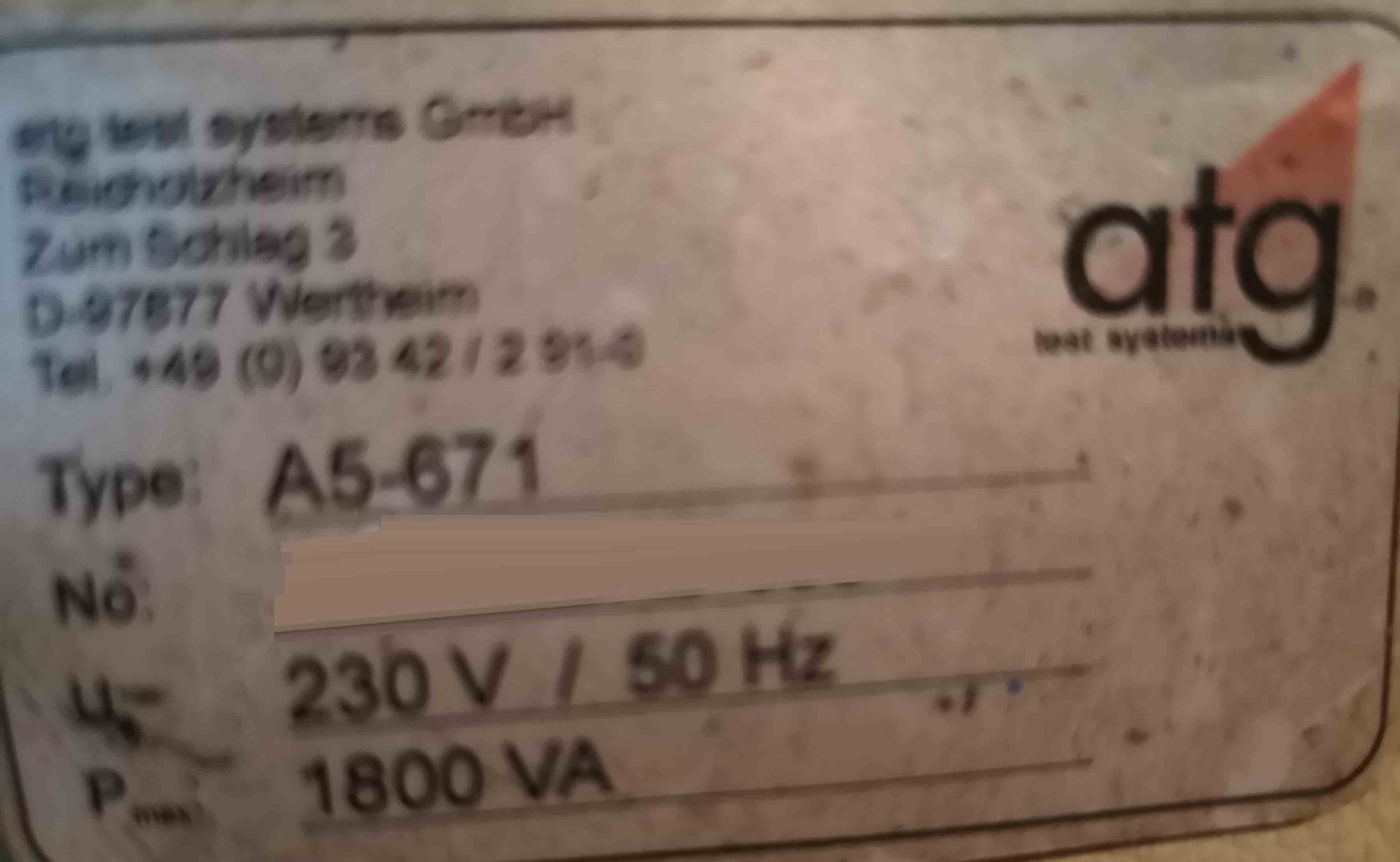

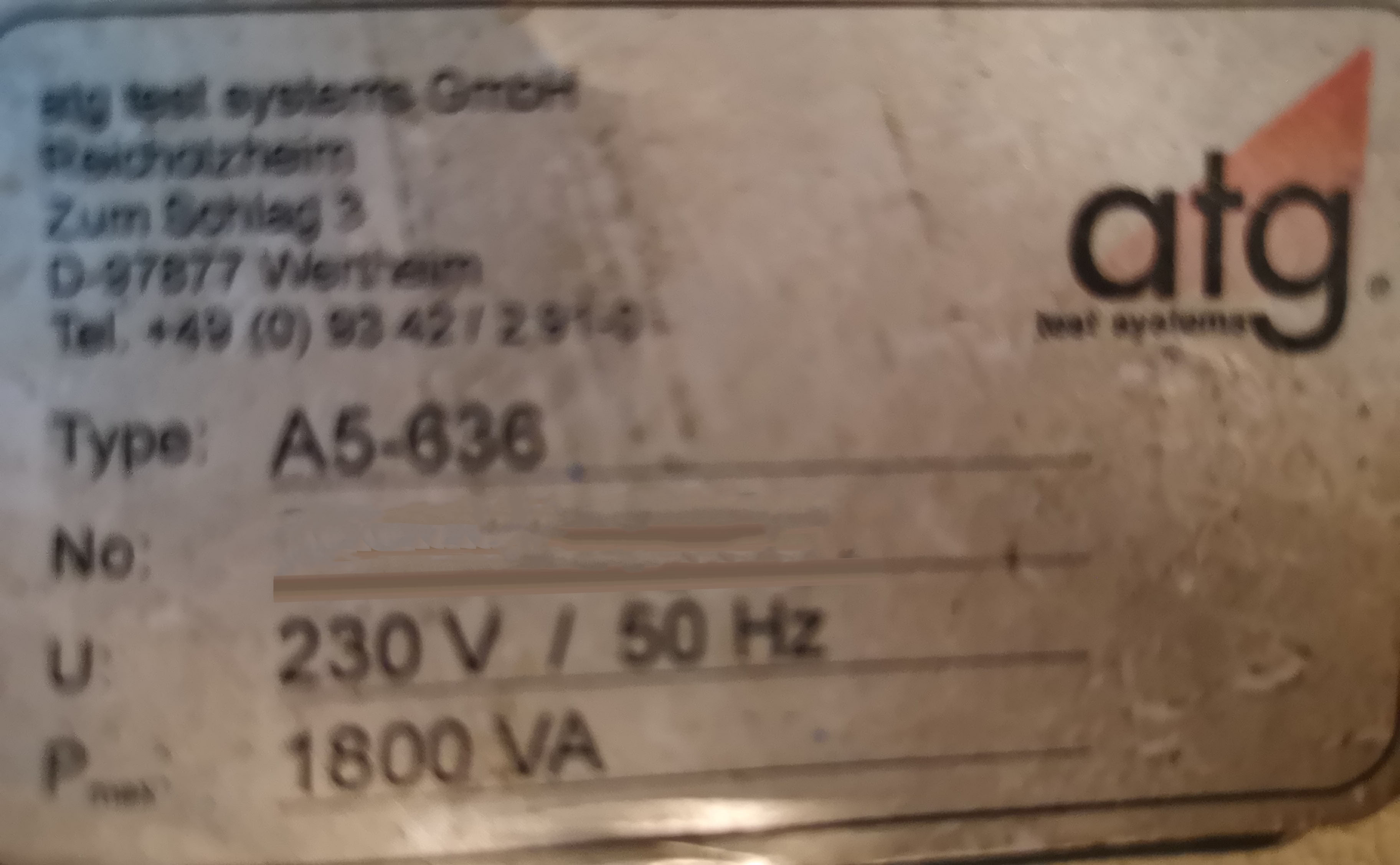

Used ATG A5 #9359870 for sale

URL successfully copied!

Tap to zoom

ID: 9359870

Vintage: 2006

Flying probe testers

Upgraded with TestPlayer2 Component (R/L/C) Test option

(2) Calibration plates included

2006 vintage.

ATG A5 is an advanced PC Board Test System designed for modern electronics manufacturing. It is designed to meet the needs of the highly automated factory environment and to easily integrate into automated production lines. A5 offers a range of sophisticated testing capabilities, combining elements of optical inspection, X-ray imaging, in-circuit test, functional test, and automated optical inspection (AOI) into a single test and inspection station. ATG A5 includes a comprehensive suite of diagnostics and production test software in order to diagnose and monitor components during the manufacturing process. The unit's X-Ray imaging, optical inspection, and in-circuit testing capabilities help identify defective components and connections while retaining quality. Additionally, A5 utilizes multiple testing methods to ensure accuracy and reliability. With multiple optical methods of characterizing elements including color check, mask check, mark/legend check, component presence, component values/type, lead presence, lead termination, lead deformation, and much more, ATG A5 is able to provide an accurate representation of component performance. A5 also features a Flexible Macro System designed to allow for custom scripts and test procedures. Users have the flexibility to customize their tests to meet specific application needs. This feature allows ATG A5 to be more reliable in difficult environments and for difficult applications, such as for medical device manufacturing. Additionally, the machine is capable of powering up the PC board to run tests such as voltage drop and memory tests. A5 includes a programmable, automated test cell structure that is designed to maximize throughput while minimizing human intervention. As such, it is well suited for high-volume automation and rapid product development. ATG A5 is able to execute complex test cycles while storing components and results in log tables for further analysis. This allows users to quickly and easily detect any potential issues with PC boards during the production line. In addition to its testing capabilities, A5 includes several advanced features that provides the ability to collect data and reports. This data can be used for both traceability and for product assurance. The machine features a state-of-the-art diagnostic toolbox capable of measuring a variety of parameters including waveforms/AC voltage, functionality parameters, environmental monitoring, and DC values. These functions allow users to stamp boards with a unique ID and store test data, ensuring quality and product accuracy while providing traceability. ATG A5 PC board test system is an invaluable tool for modern manufacturers, offering comprehensive testing and analysis capabilities in a single package. With its range of available diagnostics and test scripts, it is able to provide efficient and accurate test results in both high-volume production settings and for rapid prototyping.

There are no reviews yet