Used ATG / L&M 1500 #94069 for sale

URL successfully copied!

Tap to zoom

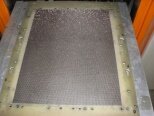

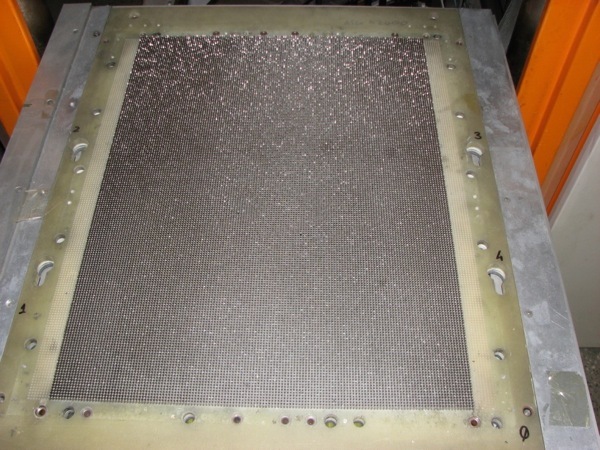

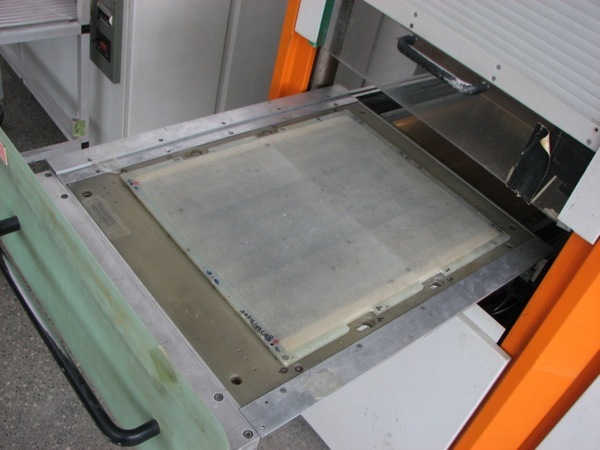

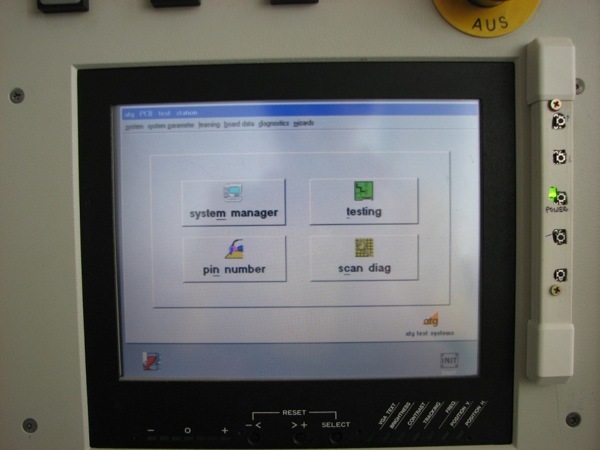

ATG / L&M 1500 is a PC board test equipment that provides fully automated test sequencing, fault isolation, and fail-safe reliability. The system uses Automatic Test Generation (ATG) to quickly and effectively determine the quality of PC board assemblies and detect any problems or defects. The unit combines adaptive test software with superior test head switching technology and high-performance analog and digital measurement systems. ATG 1500 is capable of testing both analog and digital components, such as resistors, capacitors, relays, integrated circuits, and custom-designed digital components. It is designed to provide high-quality, repeatable test patterns with high accuracy and repeatability. The machine supports a variety of on-board test protocols, including boundary scanning, waveform test sets, functional test sets, and pseudorandom test sets. It is fully compatible with several software languages, including C, C++, Visual Basic, and LabVIEW. The test sequencer of L&M 1500 can control up to 32 test heads and includes a multi-channel power bus controller to power the test heads during testing. The tool stores a full history of all test results and allows users to review the results on a local or remote computer. In addition, the asset includes an interactive color graphics interface for easy navigation and user-friendly setup. 1500 also includes a built-in database of over 2,000 components and devices to ensure fast, accurate testing. The model incorporates advanced test algorithms and comprehensive data trends to allow test engineers to detect problems quickly and with the greatest level of accuracy. ATG / L&M 1500 also supports laboratory automation and advanced L&M technology, such as Delta-Delta and Delta-Based testing. ATG 1500 is a cost-effective solution for PC board testing and is designed to deliver reliable test results while ensuring maximum levels of safety and performance. The equipment can be quickly programmed and adapted to fit any configuration, making it a powerful and flexible solution for any electronic manufacturing environment.

There are no reviews yet