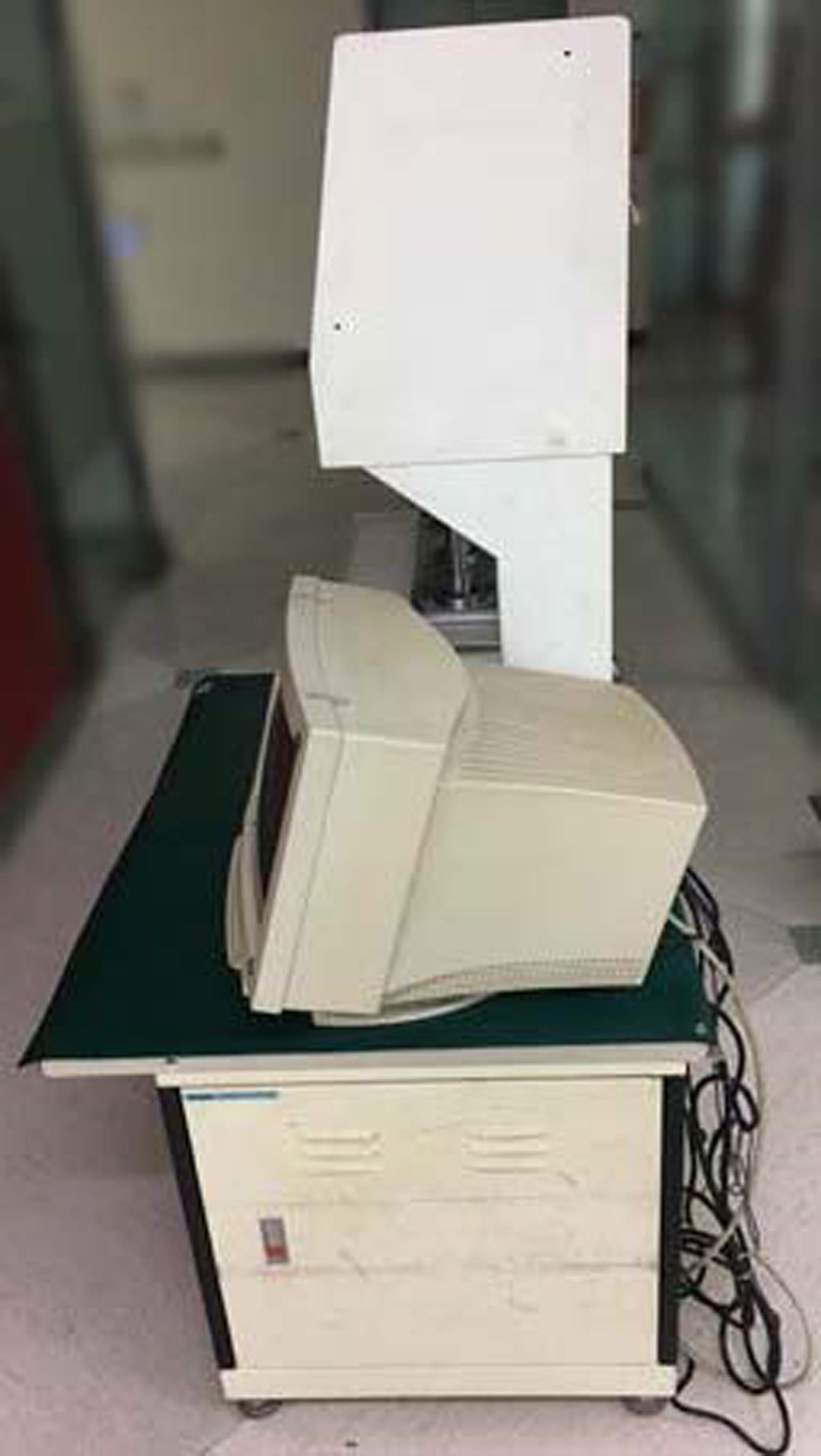

Used JET JET-300 #9155563 for sale

URL successfully copied!

Tap to zoom

JET JET-300 pc board test equipment is a computer control system designed to reduce testing costs while optimizing quality testing. It is a smart, efficient, and highly reliable unit that increases the overall testing throughput for circuit boards used in consumer electronics devices. JET-300 utilizes different methods of testing designed to ensure the highest levels of quality and accuracy. It can test boards quickly and accurately in three ways: analog, vector, and speed. It does this through a suite of automated techniques, including visual inspection, voltage tests, functional testing, power current tests, leakage tests, and waveform measurements. The analog testing allows JET JET-300 to rapidly detect any analog faults on a circuit board. It uses a high-sensitivity voltage meter to detect any minute voltage abnormalities that could lead to a malfunction. The vector testing uses scans to detect any discrepancies in logic timing or direction on a given board. The speed testing uses various methods to measure the response time on a board and can identify potential speed related problems, as well as reveal problems with power consumption. JET-300 also can be programmed to conduct specific tests on demand or set up for periodic tests. The on-board microprocessor also allows for real-time monitoring, reporting, and the generation of records to ensure traceability for compliance and regulatory requirements. It also allows for enhanced flexibility and scalability, with the ability to add various extensions, such as I/O lines, up to six cards, and various analyzers. JET JET-300 pc board test machine is an advanced solution for testing circuit boards that can reduce testing costs, speed up testing throughput, and ensure compliance with quality and safety standards. Its efficient design, accurate testing, and numerous features maximize the productivity and optimize the process of assembly line testing, making it the ideal choice for any high-volume manufacturing environment.

There are no reviews yet