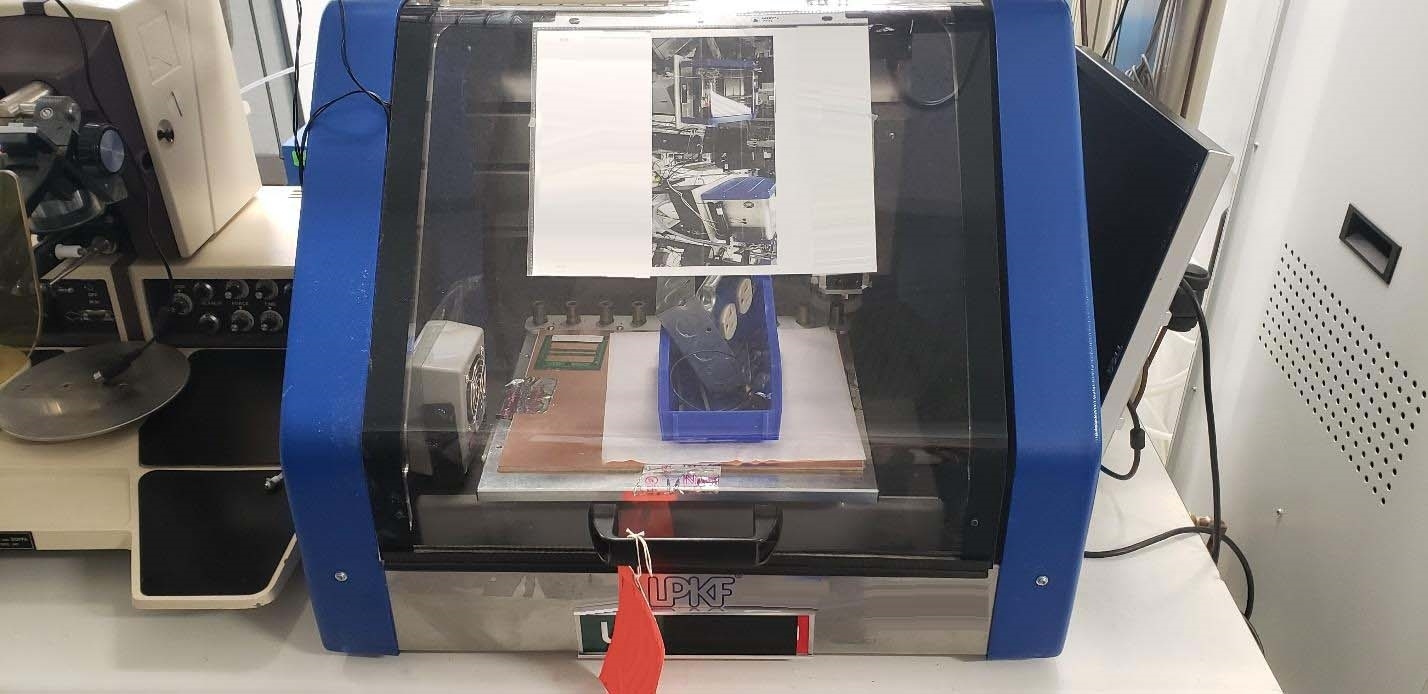

Used LPKF S62 #9287476 for sale

URL successfully copied!

Tap to zoom

LPKF S62 is a PC board test equipment for analyzing and inspecting the functional integrity of circuit boards. The system provides a comprehensive, fast, and reliable quality assurance solution for production management. Its hardware components include a Computerized Numerical Control (CNC) milling machine, an integrated tool set, and a vision unit. The CNC milling machine has a micro-drilling spindle that is capable of drilling extremely precise holes with a maximum drilling depth of 0.3 mm. This allows for the milling of small holes as well as other intricate geometric patterns. The integrated tool set comprises of special hobby tools, such as a soldering iron and tweezers, as well as various measuring tools, such as an edge finder, a ruler, and a caliper. The vision machine uses an image sensor combined with a microscope to detect and analyze the presence of solderpaste on the board. S62 is ideal for ensuring quality in production lines where components are handled and moved at a fast pace. It is suitable for use in both manual and automated processes, and can easily detect defects on complex designs. Its advanced features, such as the ability to customize the test parameters, and its interactive software, make it a highly versatile testing tool. The asset is designed to provide reliable and consistent test results over multiple tests, and has been tested with many different types of boards. This ensures that it can accurately detect defects in a variety of circuit board designs. In summary, LPKF S62 is a comprehensive, accurate, and easy-to-use circuit board testing model that enables the reliable detection of faults and defects in circuit boards, helping to ensure the quality of production lines that operate at high speed.

There are no reviews yet