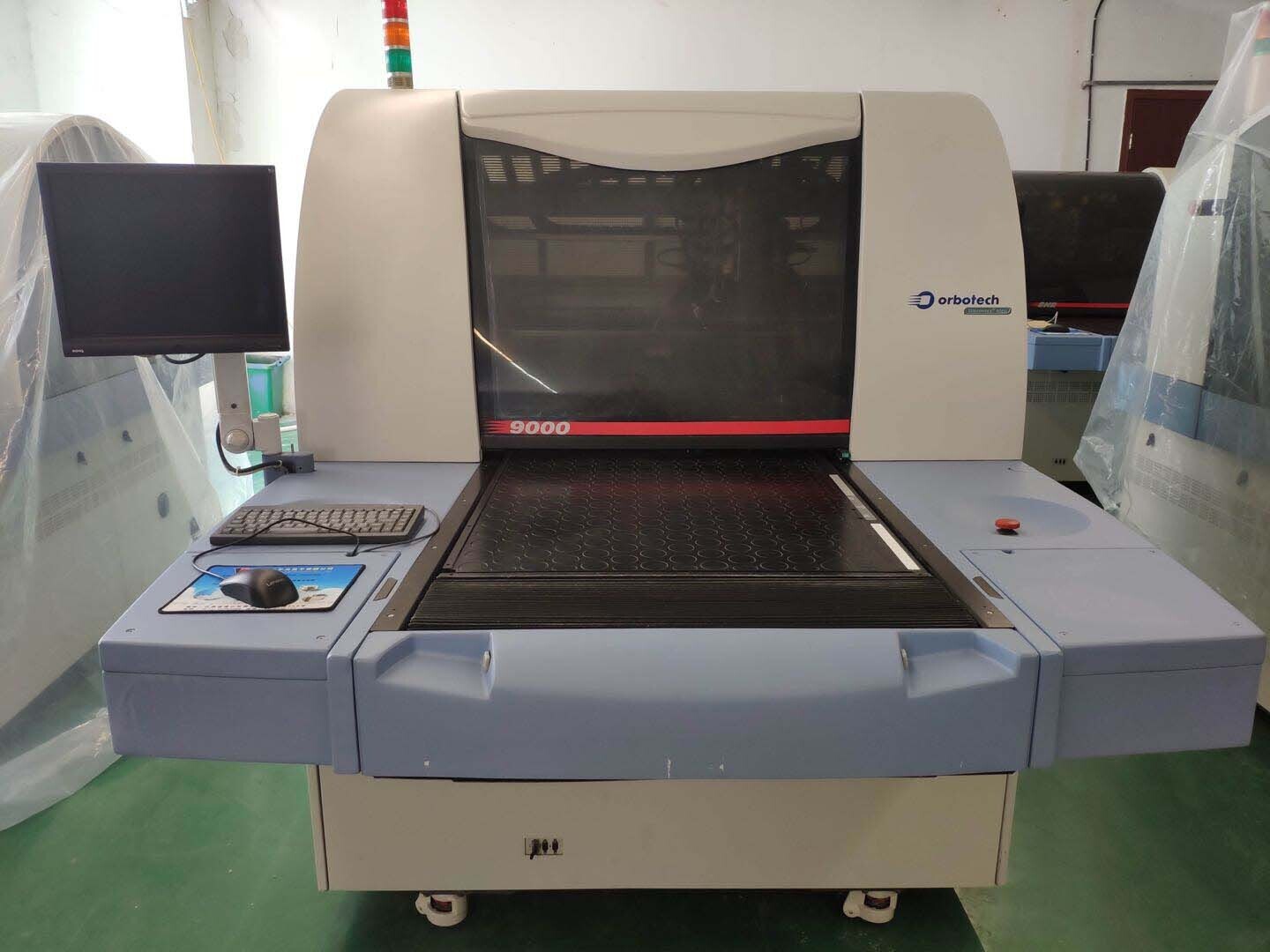

Used ORBOTECH Discovery 9000 #9313152 for sale

URL successfully copied!

Tap to zoom

ID: 9313152

Vintage: 2012

Automatic Optical Inspection (AOI) system

With table

Table size: 26x31

Veriwide: 26x32

Range: Down to 1.2 mil (30 μm) line and space

Panel dimensions:

Thickness range: 1-300 mil (25-7500 μm)

Maximum panel size: 26" x 24" (660 x 610 mm)

Maximum inspected area: 26" x 31" (660 x 787 mm)

Throughput:

Line width (mil) / (μm) / Sides/Hour

4 / 3 / 2 / 1.4 / 1.2

100 / 75 / 50 / 35 / 30

220 / 210 / 180 / 125 / 105

Based on panel size: 18" x 24" (457 mm x 610 mm) With 1" margin

Defect verification:

Verification and repair stations:

VeriSmart

VeriWide

VeriFine

VeriSmart-A

VeriWide-A

VeriFine-A

VRS-5m

VRS-5

VRS-5st

VRS-4Pro

On-system verification: Built-in video camera

Setup data sources: CAM

Panel registration method: Pinless registration - Panel edge alignment

Option: Amethyst technology

2012 vintage.

ORBOTECH Discovery 9000 pc board test system is an all-in-one, automated optical test solution designed to reduce costs and improve quality in production testing and validation of printed circuit boards (PCBs). With its enhanced performance and intuitive user interface, Discovery 9000 achieves higher levels of accuracy, repeatability, and traceability while maintaining a small footprint in the production environment. ORBOTECH Discovery 9000 offers superior performance in terms of defect identification, positioning precision, and the accuracy of test results. Its advanced 3-dimensional imaging optics capture up to 96 images of the target PCB, taken from multiple angles, and then mathematically combine them into a single image without any file stitching. This single, accurate image provides a comprehensive view of the PCB circuitry with excellent defect identification and positioning precision. Discovery 9000 utilizes optically triggered edge analysis to accurately locate connectors, components, vias, or other board infrastructures. This technology greatly enhances the accuracy of test results. The advanced edge analysis feature enables advanced part offline programming to further improve part placement accuracy and the ability to quickly detect any missing components. The advanced OFFLINE programming feature of ORBOTECH Discovery 9000 enables quick and easy test creation and validation. The operator can easily do part offline programming by simply creating the program, validating it, and then executing it. The part offline programming also eliminates operator errors and minimizes the time required for programming the tests. The intuitive user interface of Discovery 9000 improves user productivity and minimizes training time. It offers comprehensive test functions and graphical aides that simplify navigating through the different layers of the printed circuit board. Additionally, an application-specific suite of software tools optimized for defect identification and network analysis help to further simplify the process of board test validation. ORBOTECH Discovery 9000 helps to improve the quality and overall cost reduction by providing accurate, repeatable, and traceable test results. The system is engineered to reliably detect a range of defects such as shorts, opens, leakages, mis-modulations, and missing components. Its high-speed, fully automated optical inspection process helps to eliminate the need for costly manual inspections. In conclusion, Discovery 9000 pc board test system is an all-in-one, automated optical test solution designed to improve quality, reduce overall costs, and improve productivity in production testing and validation of printed circuit boards.

There are no reviews yet