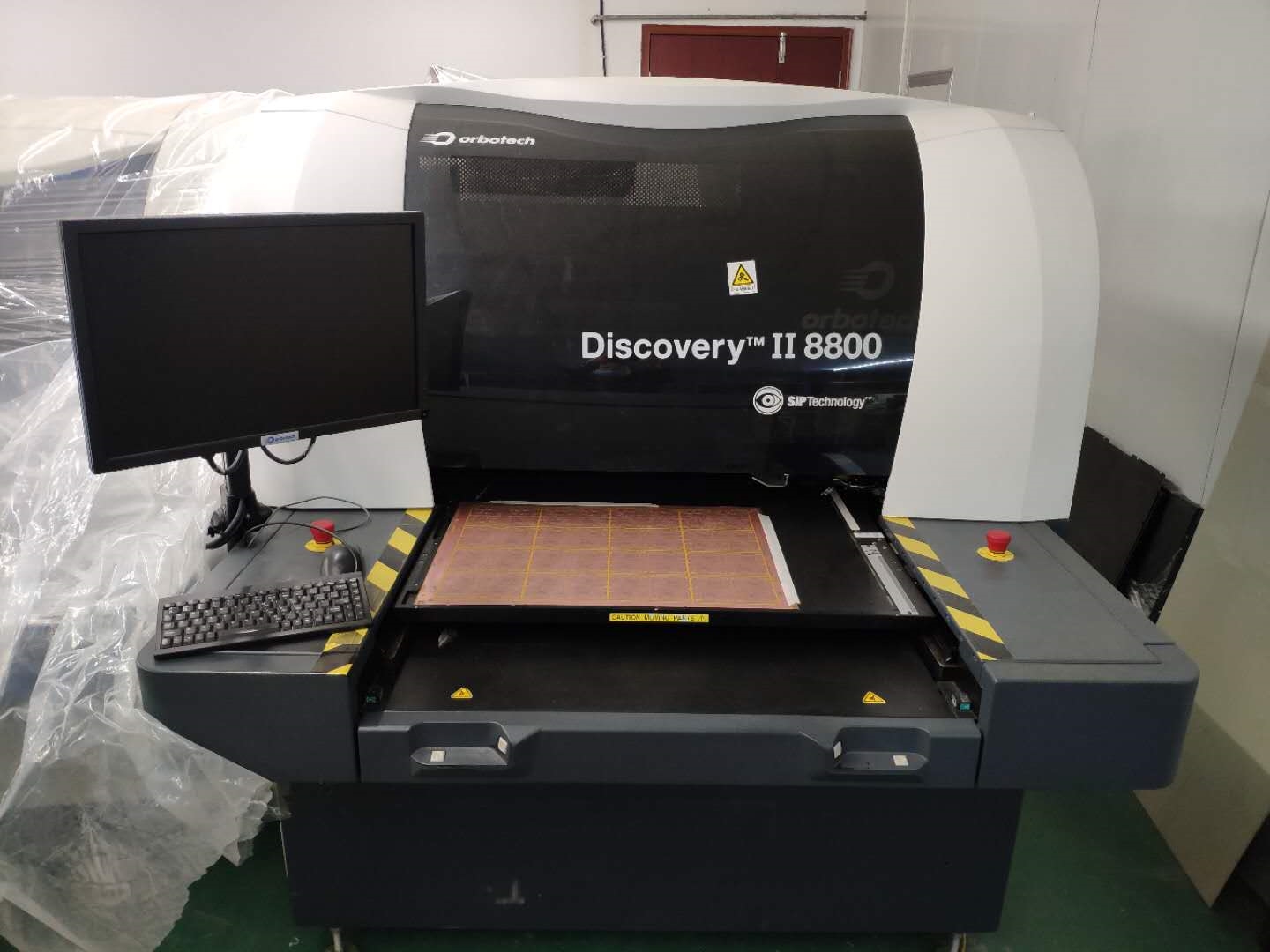

Used ORBOTECH Discovery II 8800 #9278137 for sale

URL successfully copied!

Tap to zoom

ORBOTECH Discovery II 8800 is a high-performance, versatile, and flexible Printed Circuit Board (PCB) test equipment designed for testing and programming of multiple product types in a single machine. Built on a modular platform, the open-architecture of the 8800 provides users with the ability to customize a set of fixtures and test head configurations to fit their specific production requirements. The system features an input/output (I/O) unit providing a variety of connection interfaces such as vacuum, VME, PXI, camera, and others. The 8800 has a powerful software suite capable of managing images, analyzing results, executing tests, and reporting findings in a user-friendly graphical interface. The 8800 board test machine offers a wide variety of test capabilities, allowing users to automate the process of component validation and assembly, from the rudimentary steps of component location and validation step to the more complex stages of repair, rework and refurbishment. The tool can handle various surface mount device and through-hole part families, from a single leaded or leadless part, to a complex array of components on multiple sides of the board. The 8800 test asset also offers advanced visual inspection capabilities, allowing users to inspect individual components as well as their interconnects to validate overall functionality and board structure. The 8800 has an automatic placement/pick-and-place model enabling users to reliably place components in the correct locations with a higher degree of accuracy. The equipment also has an optical centering system and a vision testing unit that can detect any defects down to 0.1mm. It can even detect solder deformations, lifted pins and batch defects. The 8800 features a fully compatible board handler that can transport boards quickly and accurately for multiple direct-probing applications. The 8800 is powered by an advanced Multi-Axis Table (MAT), enabling higher speeds and improved accuracy in all test operations. The machine utilizes parallel porting technology, allowing users to connect up to 16 instruments and transducers, simultaneously receive data, and run tests up to 5000 times per second. Additionally, the tool supports advanced networking capabilities for remote testing through Ethernet; and can be customized to monitor the performance of multiple sectors within a single machine. The 8800 is also designed to be energy efficient and environmentally friendly, featuring a low power consumption rate of no more than 1.4kW/h. All safety features have been exactingly tested and certified. The asset's user-friendly design and intuitive graphical interface ensures a short learning curve and greater productivity for personnel in all phases of production. With its adjustable design, the 8800 model can be easily modified and adjusted according to changing production requirements.

There are no reviews yet