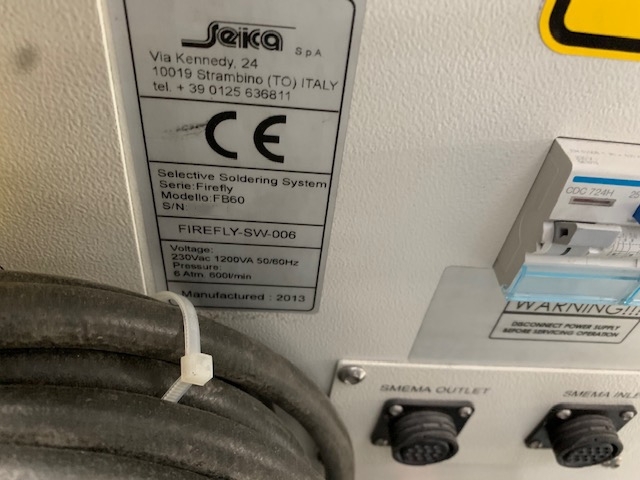

Used SEICA FB 60 #9244976 for sale

URL successfully copied!

Tap to zoom

SEICA FB 60 is a PC Board Test Equipment that is capable of providing a comprehensive diagnosis of printed circuit board (PCB) assemblies. It is capable of testing against numerous functional and performance parameters such as component arrival, supply voltage, analog and digital signal analysis, current leakage and surge voltage. FB 60 is a fully automated test solution that uses a combination of inspection, component electrical test, functional test, and boundary scan test, to diagnose production PCBs. The system's inspection stage uses X-ray inspection to identify components and assess their condition. This is followed by electrical tests to verify actual component data against a set of defined parameters. The functional test stage verifies the correct working of all components with various operating modes. The final step of the diagnosis includes the boundary scan test, which is used to detect the correct electrical connections between the components. SEICA FB 60 uses a proprietary operating unit designed to facilitate collection and analysis of data as an integral part of the test solution. The machine's data collection capabilities include reporting of component attributes, component test values, and detailed diagnostic reports. The tool is designed to provide real-time data analysis and traceability of any failures during production. The asset is also equipped with automatic defect corecction and post-processing to help mitigate the effects of undetected faults. FB 60 is designed to be user friendly with a touchscreen user interface that provides quick and easy access to model functions. It also includes a real-time GUI-based graphical web interface for remote monitoring and control. The equipment is designed to be upgradable and has the option for extending its capability to include various types of test programs such as NAND Flash Program, XY coordinates verification, and charge-discharge. SEICA FB 60 provides reliable diagnoses and reliable quality checks for production PCBs. Its ease of use and ability to be remotely monitored allows it to be used in even the most complex manufacturing environments. Its advanced test capabilities give a comprehensive view of the PCB's health and allows companies to ensure the quality of their production.

There are no reviews yet