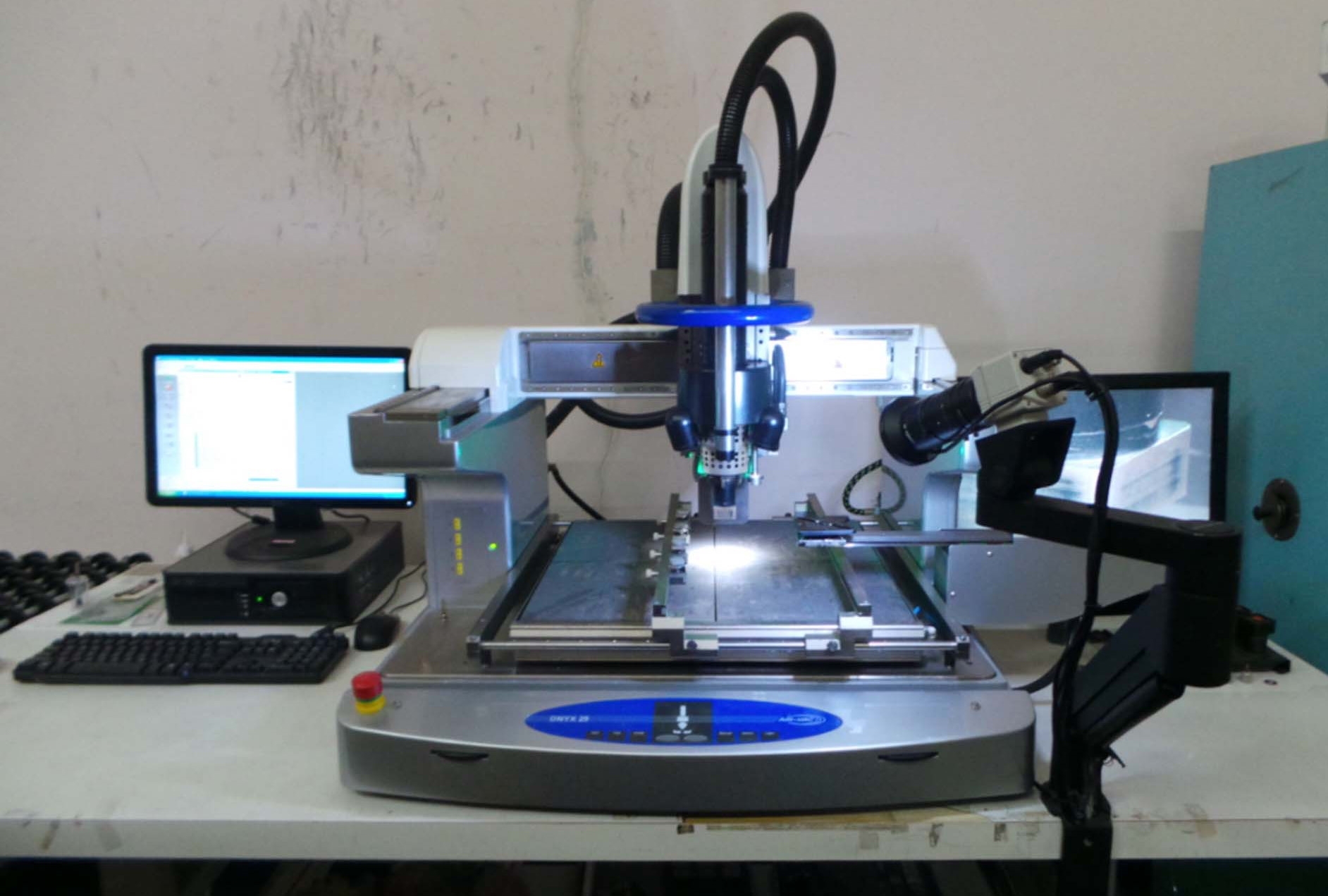

Used AIRVAC / ZEVAC Onyx 29 #9265624 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9265624

Vintage: 2005

Rework station

(9) Micron placement accuracy: 0.0003"

Precision air flow

Components: Up to 3"

Micro site cleaning

Solder dots / Lines down to 0.010"

Uniform joint temperature

Options:

Part number / Description

0029.11.041 / Pivoting IR probe with laser pointer

0029.15.041 / Carousel fixture for small board rework

0029.03.012 / Site cleaning system

- / Micro component rework and site cleaning kits

0029.02.042 / Component shuttle

0029.04.041 / Direct view camera with video monitor, 20"

- / Dipping kit for solder paste / Flux

1003.05.010 / Ergonomic workstation with CPU holder

1003.05.005 / Monitor stand option for workstation

1003.05.006 / Nozzle stand option for workstation

1003.05.007 / Locking drawer option for workstation

0029.01.052 / Topside clearance standard, 30 mm x 70 mm (2.75")

300.00.547 / Fume extraction manifold

300.00.504 / Four thermocouple ports

0024.90.047 / Thermocouple organizer

2005 vintage.

AIRVAC / ZEVAC Onyx 29 is a pc board assembly and manufacturing equipment for high efficiency assembly of printed circuit boards (PCBs). The system offers a wide range of features, including high-precision placement of components, fast multi-axis motion, and precise thermal correction for temperature-sensitive components. The unit also provides options for manual and automated placement of resistors, capacitors, ICs and other components. ZEVAC Onyx 29 machine consists of a user-friendly machine which is housed in a robust and reliable metal frame and includes the necessary equipment necessary for the assembly and manufacture of PC boards. The tool is fitted with advanced software and hardware components, such as an LCD Display, touch screen, Windows 10 PC, integrated vacuum asset, motion control model, integrated E-mark labeling equipment and a single system to control the whole functioning of the assembly. AIRVAC Onyx 29 unit is fitted with RFID technology systems which allow the scanning of RFID-enabled components to ensure accuracy of placement of components. The machine also provides a complete remote monitoring tool to provide real-time information and control. The monitoring asset also allows for scanning of components during operation and monitoring the performance of the model and the functioning of all components. Onyx 29 equipment is equipped with powerful preselection systems that provide fast and accurate component placement of components with up to 6 grids of components. The system allows for both manual and automatic loading and unloading of components, including resistors, capacitors, inductors, ICs, bipolars and much more. The unit also features a temperature-controlled environment, for thermal resistant components. AIRVAC / ZEVAC Onyx 29 machine is designed for high volume production using a highly efficient and accurately placed soldering of components, and with minimal solder joint failure. The tool is compliant with RoHS soldering and is suitable for lead-free as well as leaded soldering. The asset also helps prevent harmful emissions and is compliant with most industrial safety standards. ZEVAC Onyx 29 assembly and manufacturing model is a high-performance equipment designed for efficient and accurate production of PCB assemblies. The system's wide range of features makes it suitable for a variety of applications, from the high-volume production of complex assemblies, to the quick prototyping of simple PCBs. The unit's advanced features, such as the modular architecture, high-precision components, accurate placement systems and thermal control, make it an ideal tool for many commercial and industrial PCB assembly requirements.

There are no reviews yet