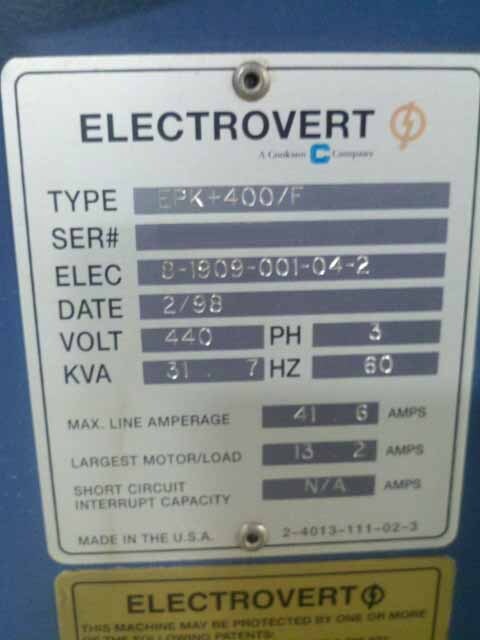

Used ELECTROVERT EPK 400/F #9173395 for sale

URL successfully copied!

Tap to zoom

ID: 9173395

Vintage: 1998

Wave soldering machine

SMEMA: False

Volts: 440

Phase: 3 Phase

Amps: 41

Hertz: 60

KVA: 31

P.S.I: 80

Options:

19" Conveyor width

L&V Shape fingers

Finger cleaner

Spray fluxer

Light tower

Fire prevention system

USI Optiflux

(2) Lower convection Preheaters

Dual wave with rotary chip

1998 vintage.

ELECTROVERT EPK 400/F is an advanced automated soldering equipment designed for efficient and accurate PCB soldering. The system is equipped with an advanced 3-axis motion control unit that enables it to accurately position and align components to be soldered, as well as greater than normal soldering accuracy. The machine also has a powerful soldering arm, which can support up to 53" of soldering wire for those applications requiring large amounts of solder. The EPK 400/F features an integrated autofluxer, which quickly and accurately dispenses flux to the board before the soldering process begins. This ensures that the flux is evenly deposited, which improves the reliability of the solder joints and minimizes the need for operator rework. The tool also comes with an integrated vision asset, which uses a camera and sophisticated software algorithms to accurately identify components on the board. This not only enhances soldering accuracy, but also saves time and reduces any potential risk of mis-soldering. The EPK 400/F also features a high speed, fully programmable 6-axis robot which is capable of soldering at speeds up to 2500 parts per hour and can be programmed to efficiently solder complex 3-dimensional components. The model is designed to be highly reliable and easy to integrate into existing production lines or processes. It is compatible with a variety of conveyor transport systems and comes with a simple, yet comprehensive user interface for ease of use and programmability. The EPK 400/F can be configured for manual or automatic operation and is equipped with a wide range of advanced soldering tools such as a multi-process control, vacuum tower, solder cooling station, and thermocouple to measure peak temperature. Finally, the equipment features a stylized enclosure with multiple entry/exit ports, product ejectors, and integrated safety protection that meet current standards for safety and environmental protection. This makes the EPK 400/F a highly flexible and reliable system for solder process automation.

There are no reviews yet