Used JAPAN UNIX Unix-DF304S #293644188 for sale

URL successfully copied!

Tap to zoom

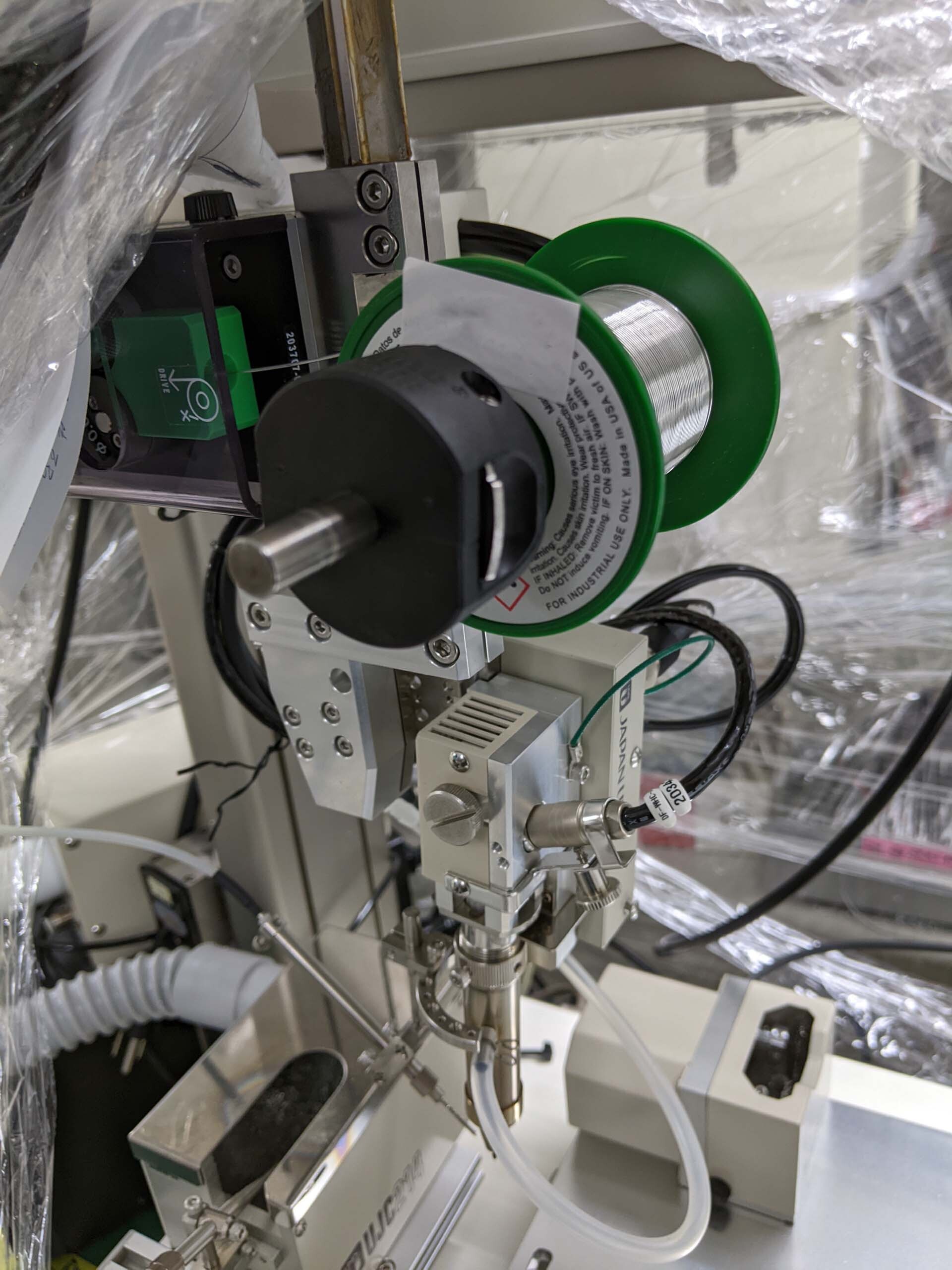

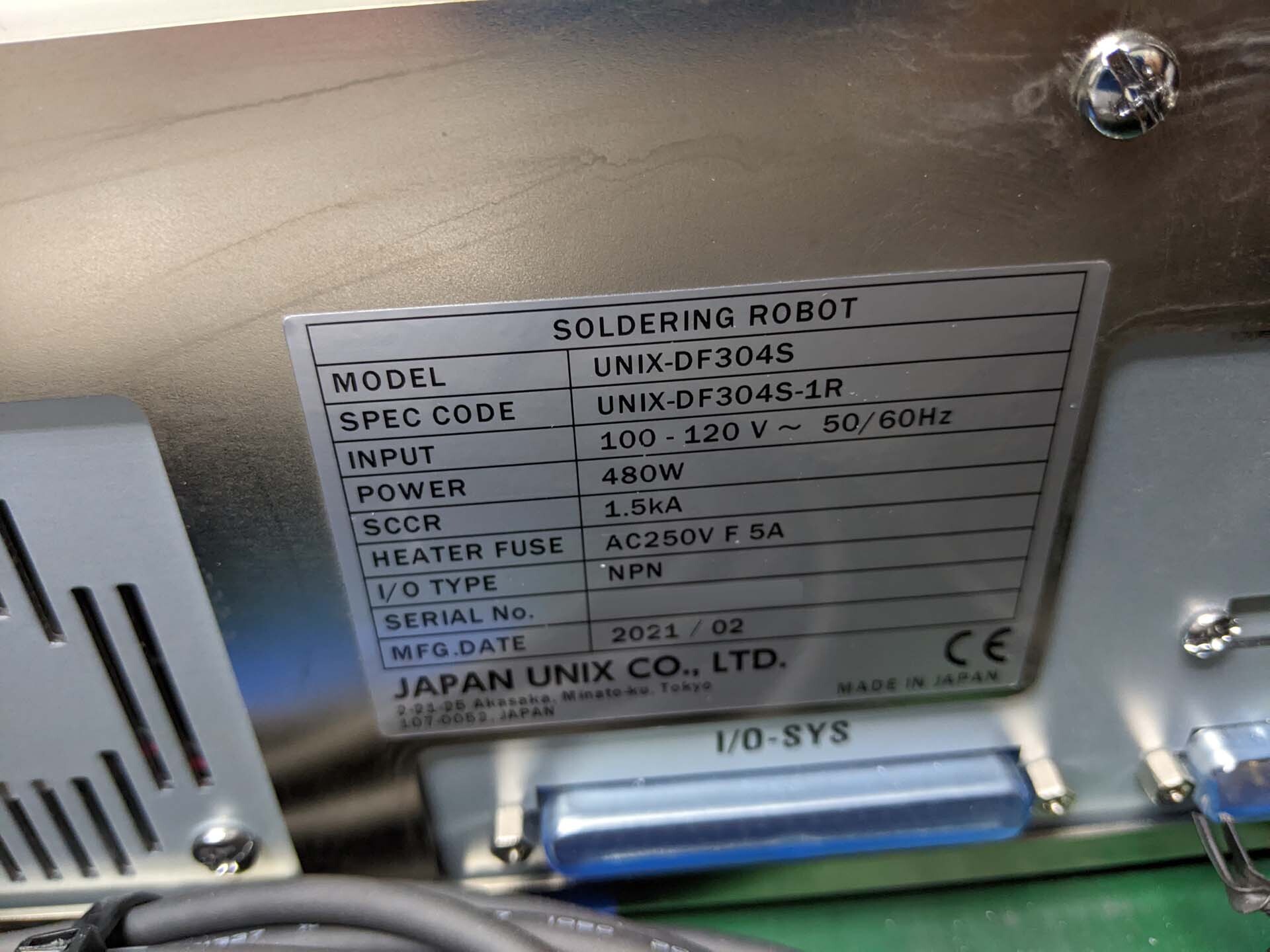

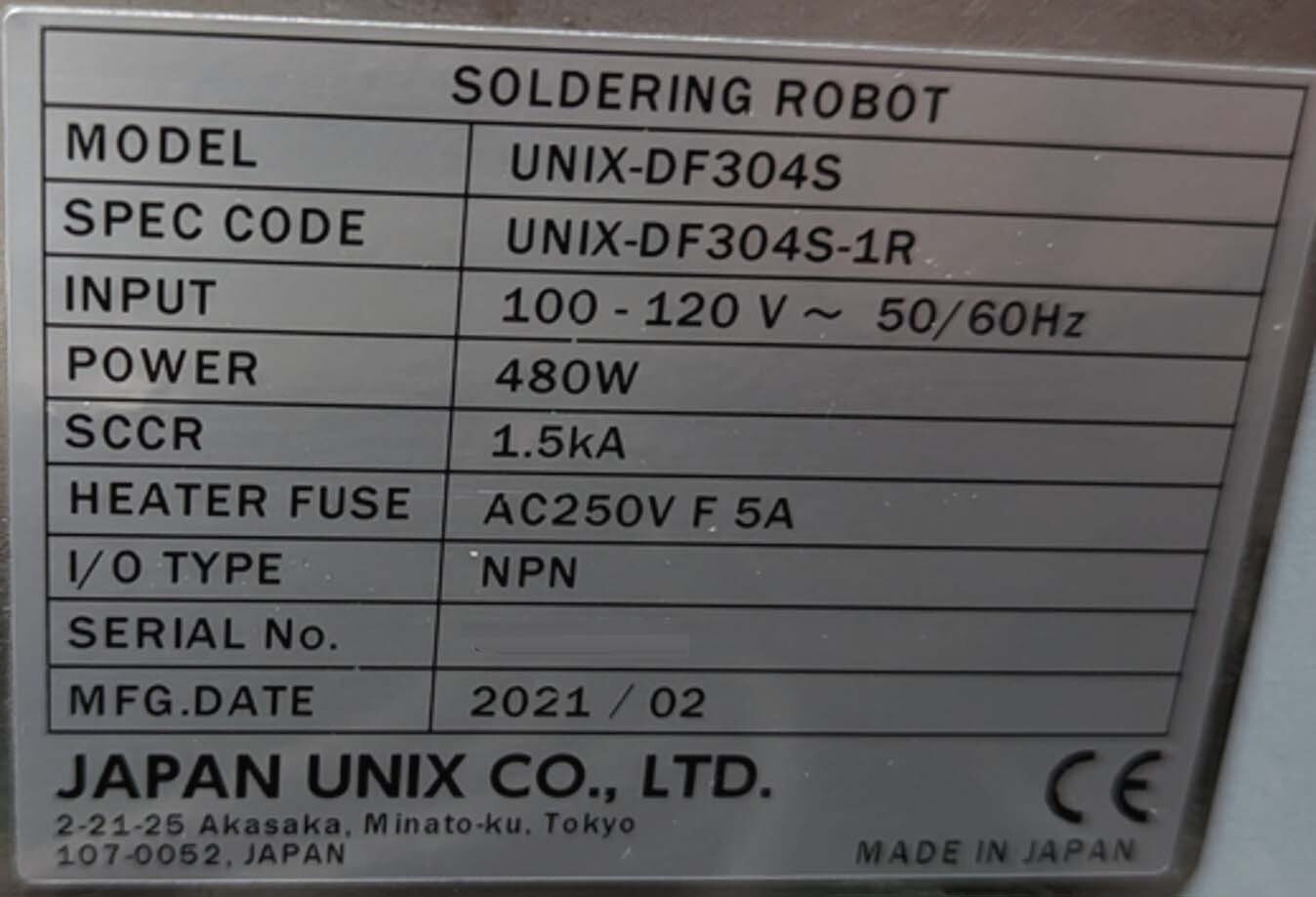

JAPAN UNIX Unix-DF304S PCB solder machine is an advanced piece of equipment, designed to make soldering quicker, easier and safer, while also increasing productivity and reducing the risk of damage to the component being soldered. The machine has a maximum soldering temperature of 480°C and a minimum reflow temperature of 150°C. The equipment has a nozzle fan function that cools down the component being soldered and a safety sensor feature which will stop the work if anything enters the work area. The machine is equipped with IC terminals and component terminals, as well as three interchangeable processing stands that can be adjusted for different soldering tasks. The IC terminals and component terminals can be quickly swapped out for different components and components in the same package. This allows for fast and efficient soldering, which reduce the time and the cost of manufacturing the PCB. The machine also has an oven system, which provides a uniform temperature for soldering and reduces thermo-mechanical stress during the soldering process. This also helps to maintain consistency and reduce lead-free soldering defects. The machine is also equipped with a high-power soldering iron, which can be used for large PCBs and has a temperature range of 250°C to 400°C. The machine also has an advanced vision unit, which can detect defects on the components being soldered. The machine requires no manual intervention and can detect any kind of production defects such as voids, shorts, opens, misalignments and bridging. The tool is capable of reading barcodes and performing an advanced analysis of the production data. The machine also comes with an operator friendly user interface, which has a 3D display and an intuitive control panel. Operation is simple and fast and the operator can access vital data on the screen. The machine also has an integrated memory asset and data management function, which allows the user to store, access and manage all the data from the different options and programs. The machine is also equipped with a quality control model, a process monitoring equipment and a fault detection system. These systems can detect and alert the user about any unexpected problems or errors that may occur during the process. The machine also has a vibration detection unit, which can detect any abnormality in the solder joint formation. To make operation easier, the machine also comes with a self-clean machine, which enables the user to clean the nozzle and other internal parts. This tool helps to reduce maintenance time and cost as well as improve the performance of the machine. Overall, Unix-DF304S PCB soldering machine is an advanced piece of equipment, which offers reliable and efficient performance.

There are no reviews yet