Used MINAMI MK-Shakeman #199612 for sale

URL successfully copied!

Tap to zoom

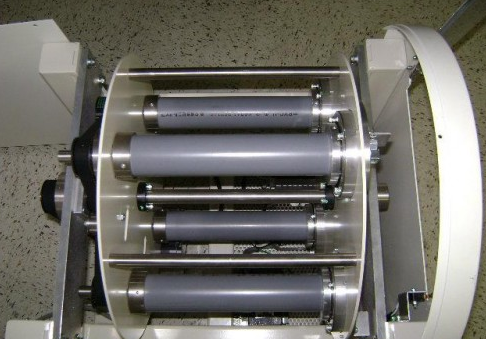

MINAMI MK-Shakeman is a high-end automated Printed Circuit Board (PCB) soldering machine used in the electronics industry. It is designed to handle quick and accurate board soldering, allowing users to effectively increase their production volume. MK-Shakeman is driven by a powerful electric motor that requires minimal maintenance for optimal efficiency. This motor is capable of delivering a high-speed shaking motion, allowing the machine to move the soldering tip rapidly over the surface of the PCB during soldering operations. The machine is also equipped with a high-precision sensor which allows it to precisely detect and position the soldering tip over the connecting points while avoiding surrounding components or other hazards. The machine's soldering head is designed with a variety of features for maximum efficiency and safety. The soldering gun is fitted with a heat sensor to automatically monitor the temperature of the soldering tip and control the application of heat. This ensures precise soldering with minimal risk of overheating components. The soldering tip is also designed with special grooves allowing it to capture and hold small components while soldering. The machine comes with an automated programming system that allows users to quickly create custom soldering patterns and program them into the machine. This makes it easy to program complex soldering operations and reduce the time spent on tediously soldering each component. The man-machine interface is designed with a user-friendly LCD touch panel and menu-driven display, making it easy to control all of the machine's features. The machine can also be integrated with computer-based control software, allowing users to monitor and control the operation from a remote location. MINAMI MK-Shakeman is a reliable and robust soldering machine that provides users with increased productivity and accuracy. It is designed to quickly and accurately solder PCBs, allowing users to meet the most demanding production targets while improving the overall quality of their soldering operations.

There are no reviews yet