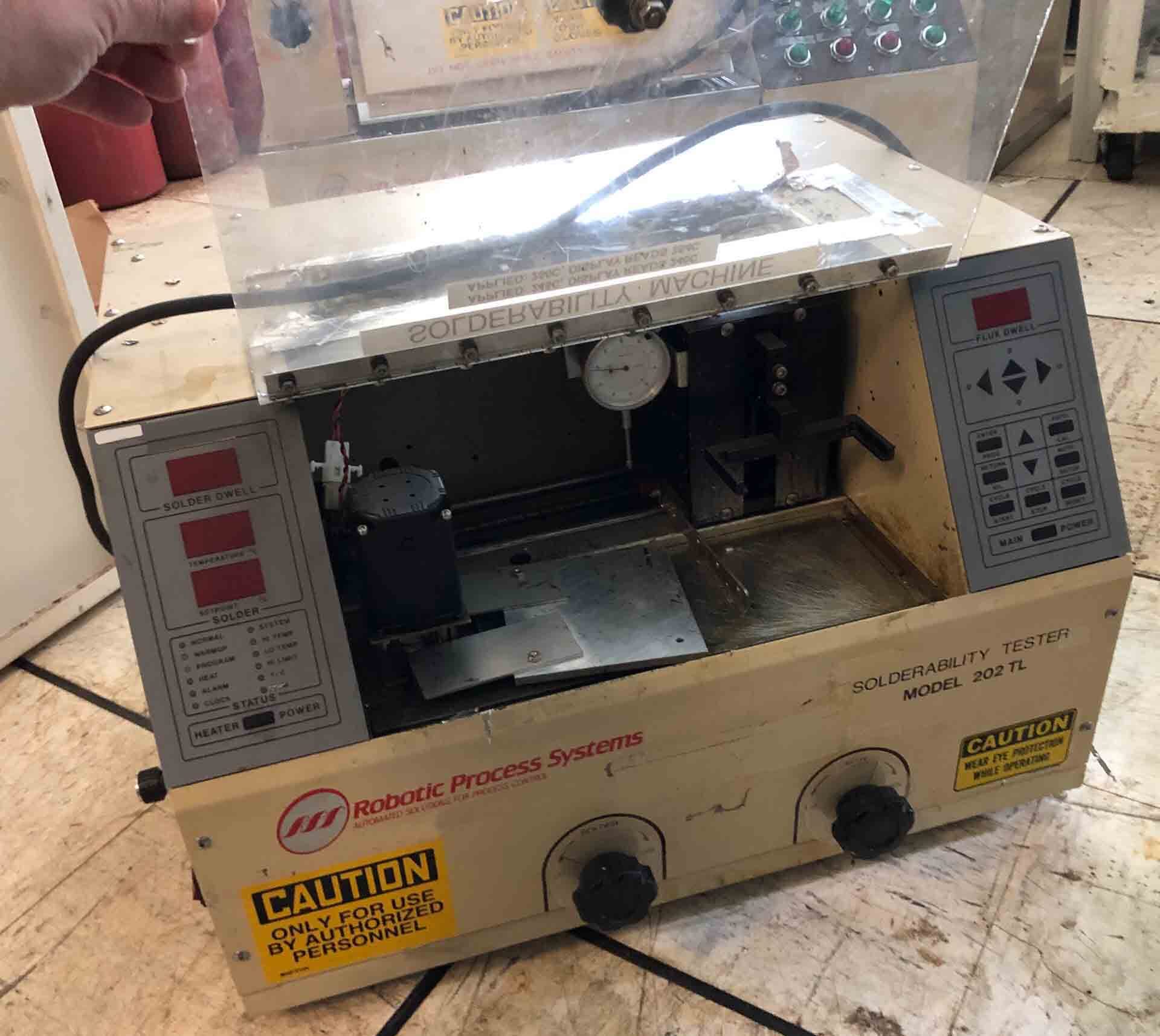

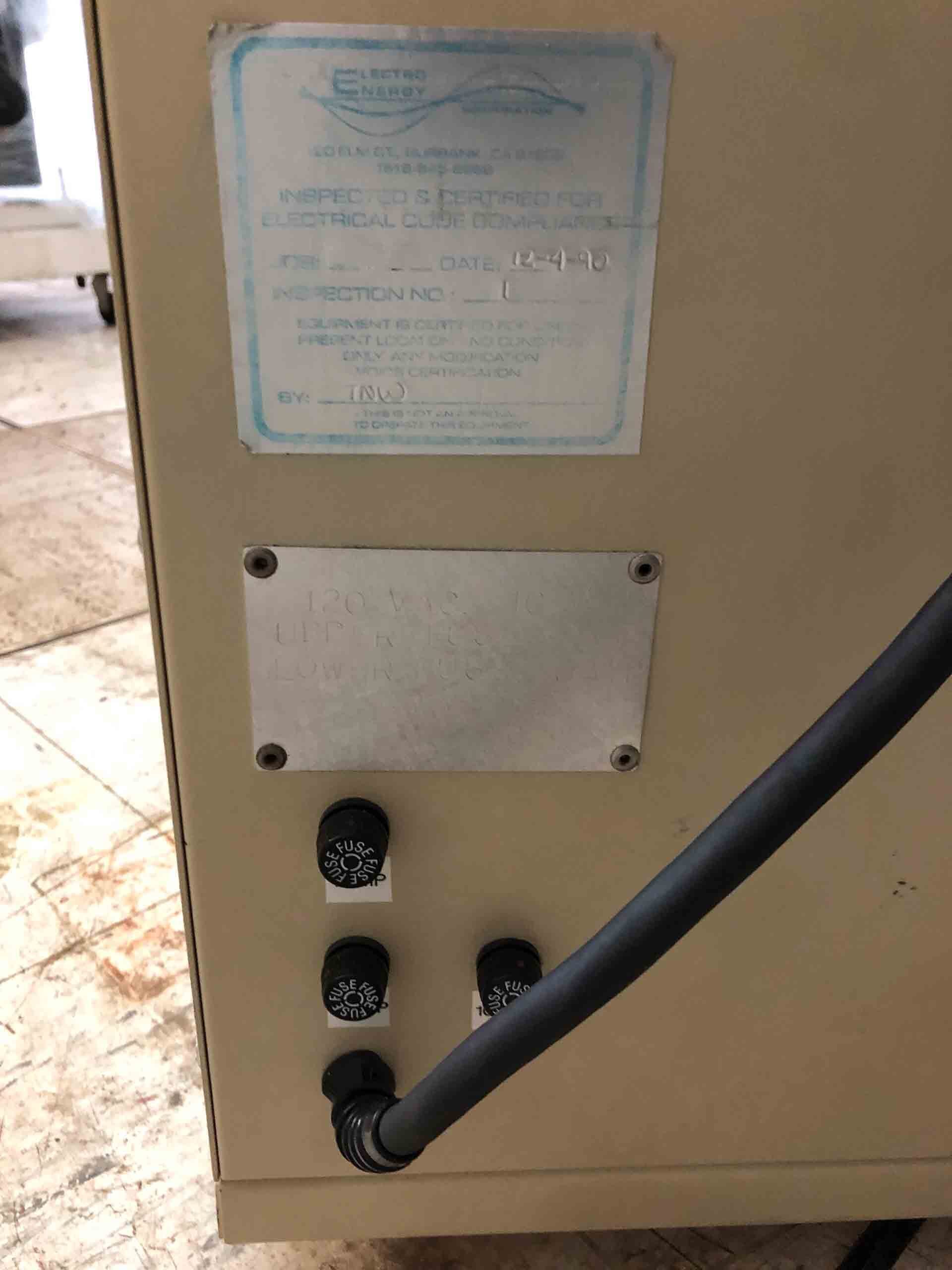

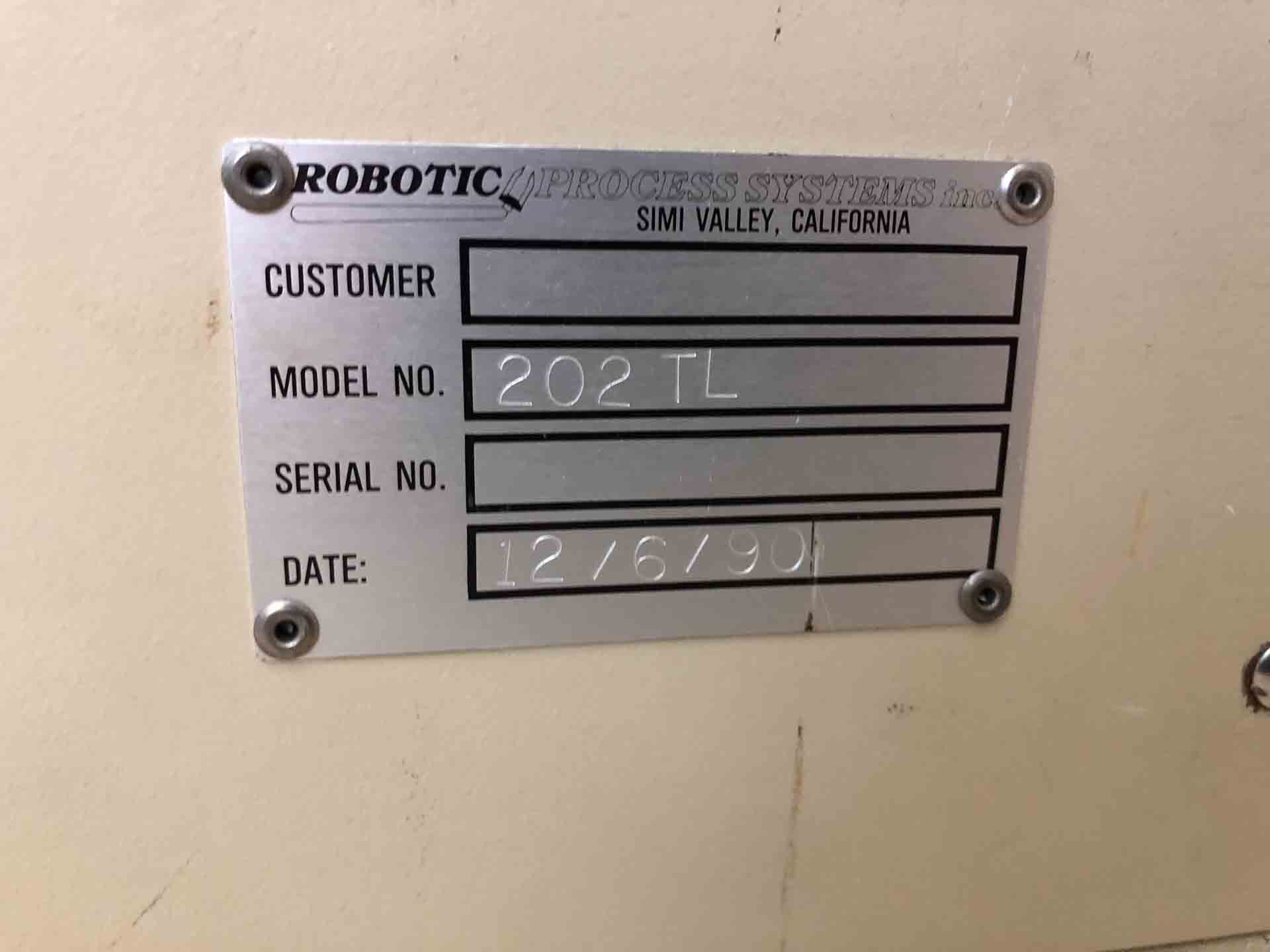

Used ROBOTIC PROCESS SYSTEMS / RPS 202TL #293600515 for sale

URL successfully copied!

Tap to zoom

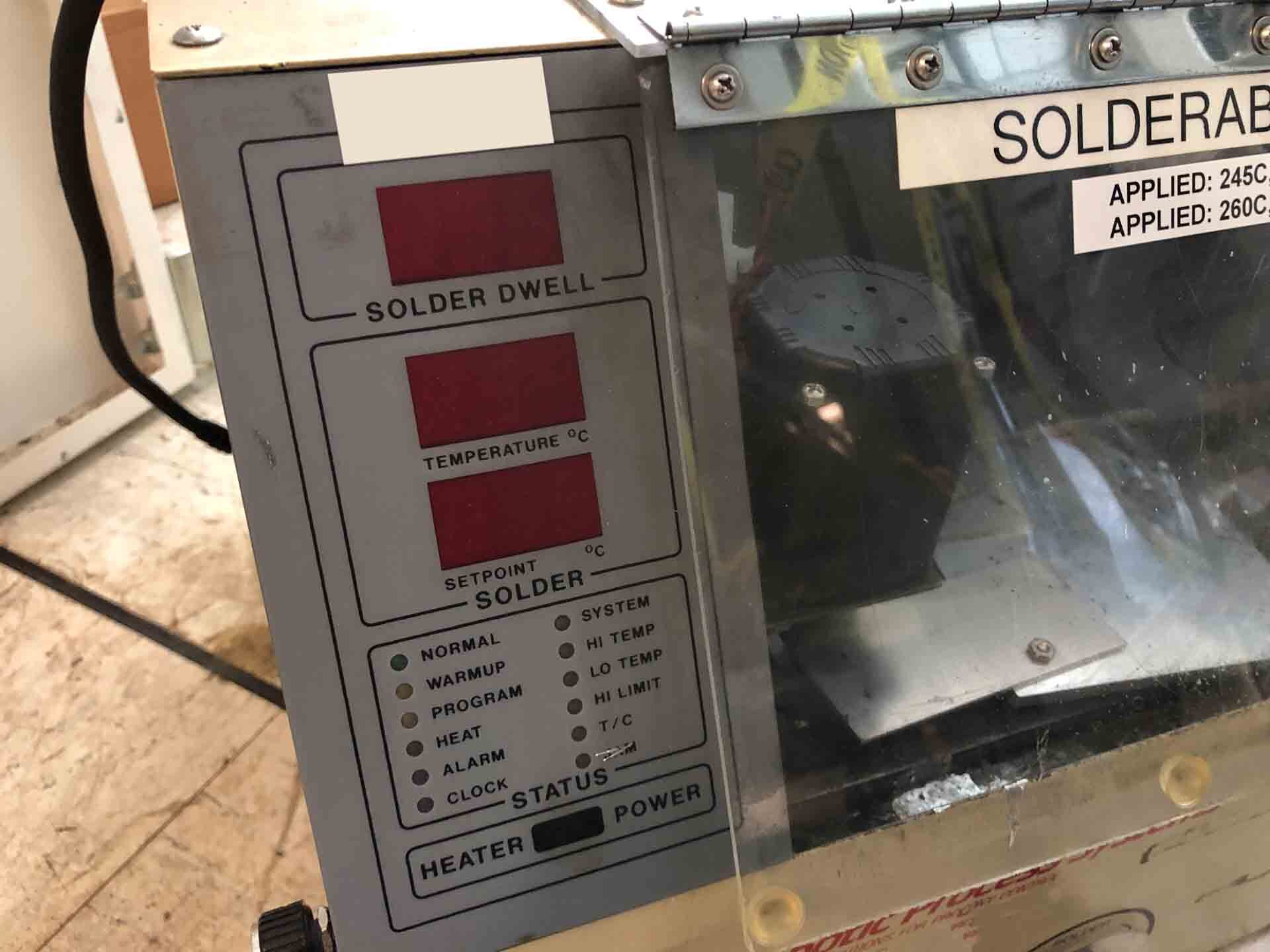

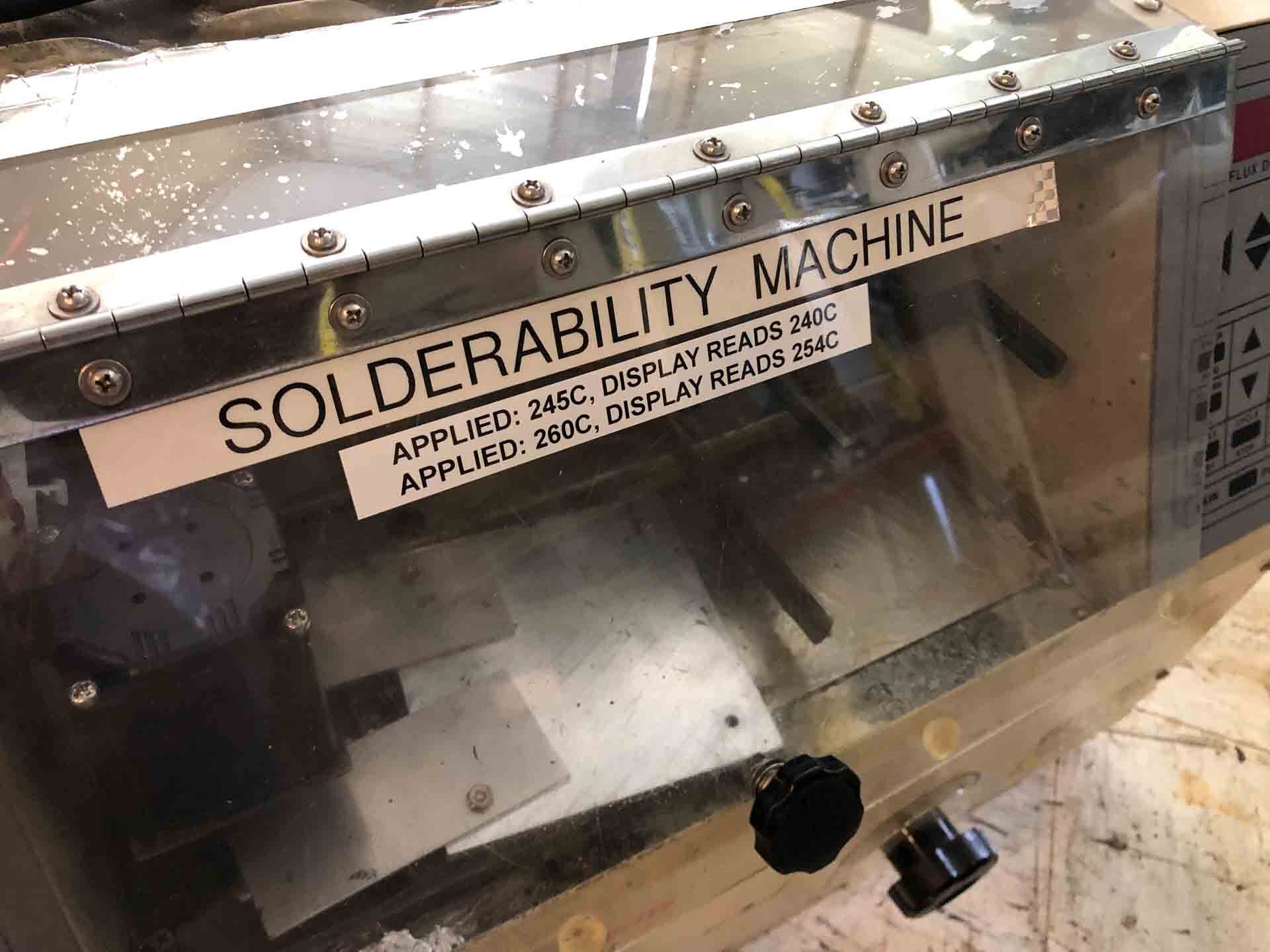

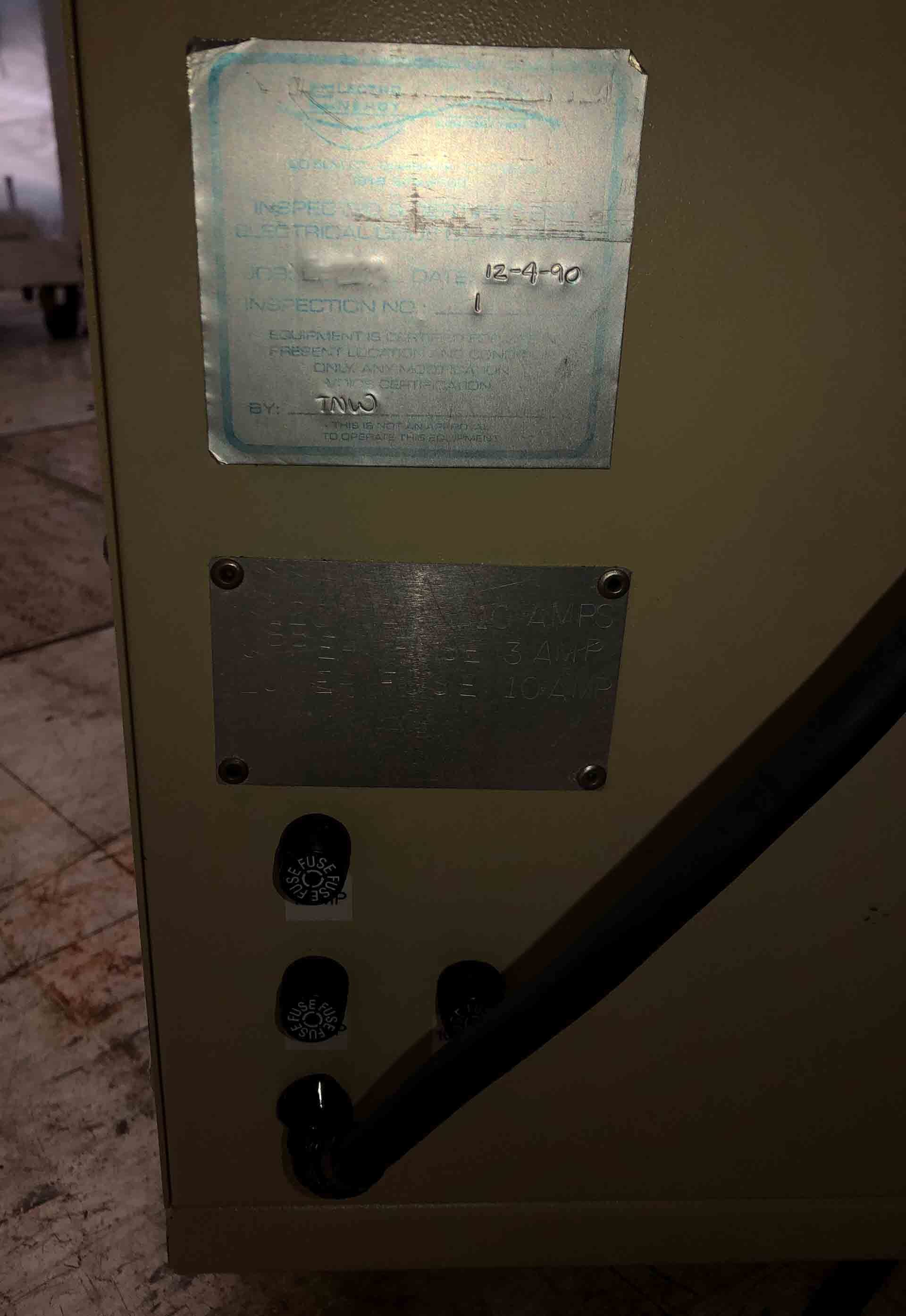

ROBOTIC PROCESS SYSTEMS / RPS 202TL is a high-precision robotic production equipment for soldering Printed Circuit Boards (PCBs). It uses advanced vision technology to accurately locate and identify components on PCBs, positioning them for accurate soldering processes. The machine is capable of working with both thru-hole and surface mount components, and has separate nozzles for soldering and re-work. The machine uses an advanced robot arm with five axes of motion. This allows the robot to move precisely in three dimensions, as well as in rotation. The robot is capable of quick and accurate motion, which allows the system to rapidly identify and move components to the soldering station. The robot arm is magnetically levitated, meaning that it also has a high degree of motion stability and accuracy. The machine is powered by a powerful operating unit that supports a variety of programmable welding operations. It can be programmed using a PC console connected to the machine, or through a human-machine interface (HMI). The operating machine also supports a variety of feedback and process analysis features to help ensure the accuracy of welds and soldering processes. Additionally, the machine is equipped with a number of safety features, including a safety latch that prevents movement when the current is interrupted and an emergency stop button. It also has a user-adjustable vacuum tool that helps keep components firmly in place during soldering. Finally, the machine is equipped with a unique laser-based vision asset, which helps to locate and recognize components on the PCBs for accurate soldering. Overall, RPS 202TL is a robust and precise robotic soldering model. Its combination of cutting-edge components, comprehensive safety features, and advanced programmable operating equipment make it an ideal choice for automated, high-precision PCB manufacturing processes.

There are no reviews yet