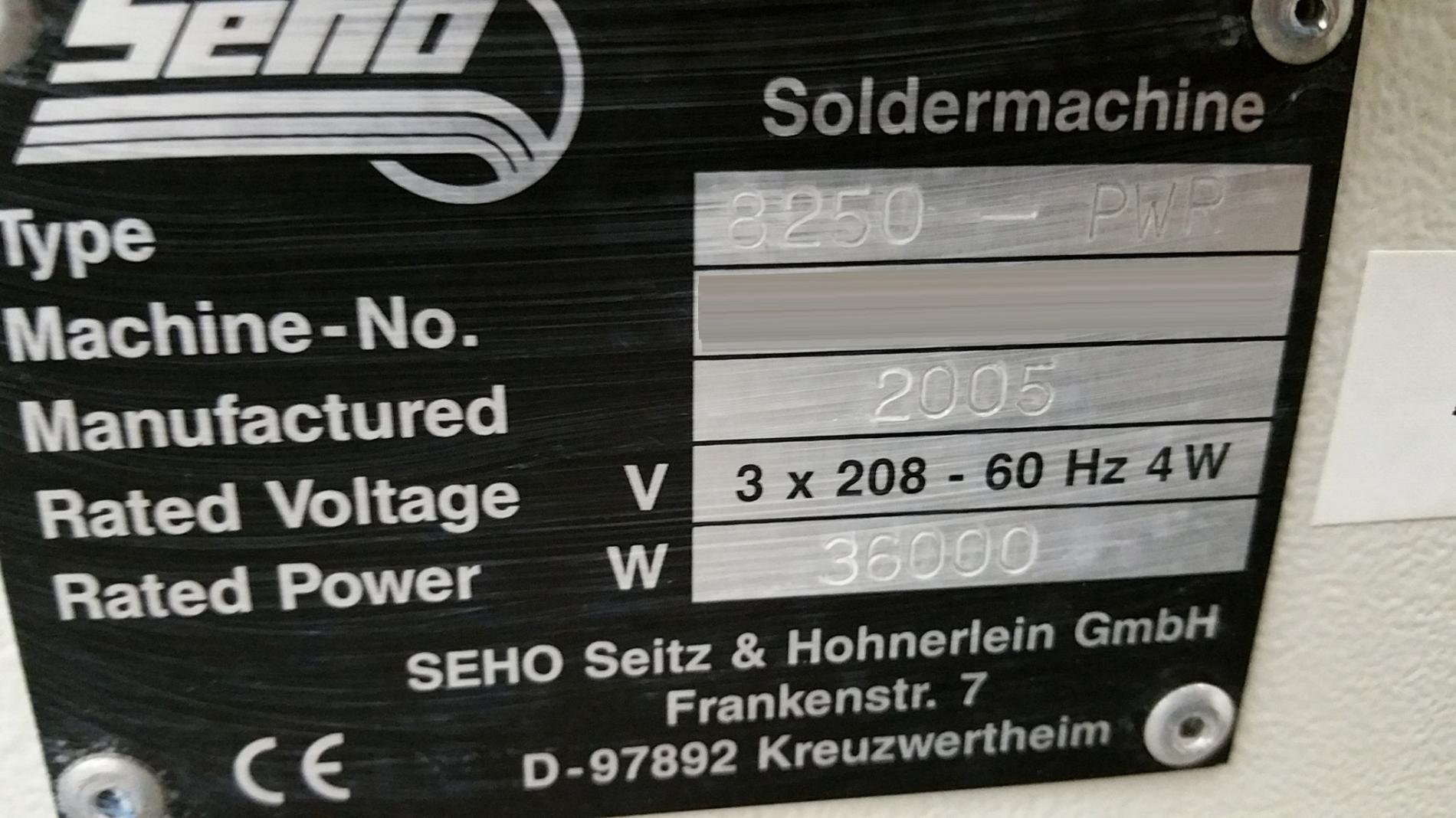

Used SEHO PowerWave 8250 #9119051 for sale

URL successfully copied!

Tap to zoom

ID: 9119051

Vintage: 2005

Wave soldering system

(4) Zones of bottom side preheat, (1) topside preheat zone

Lead free capable

Spray fluxer

Pot of lead, 63/37 solder

Laminar wave

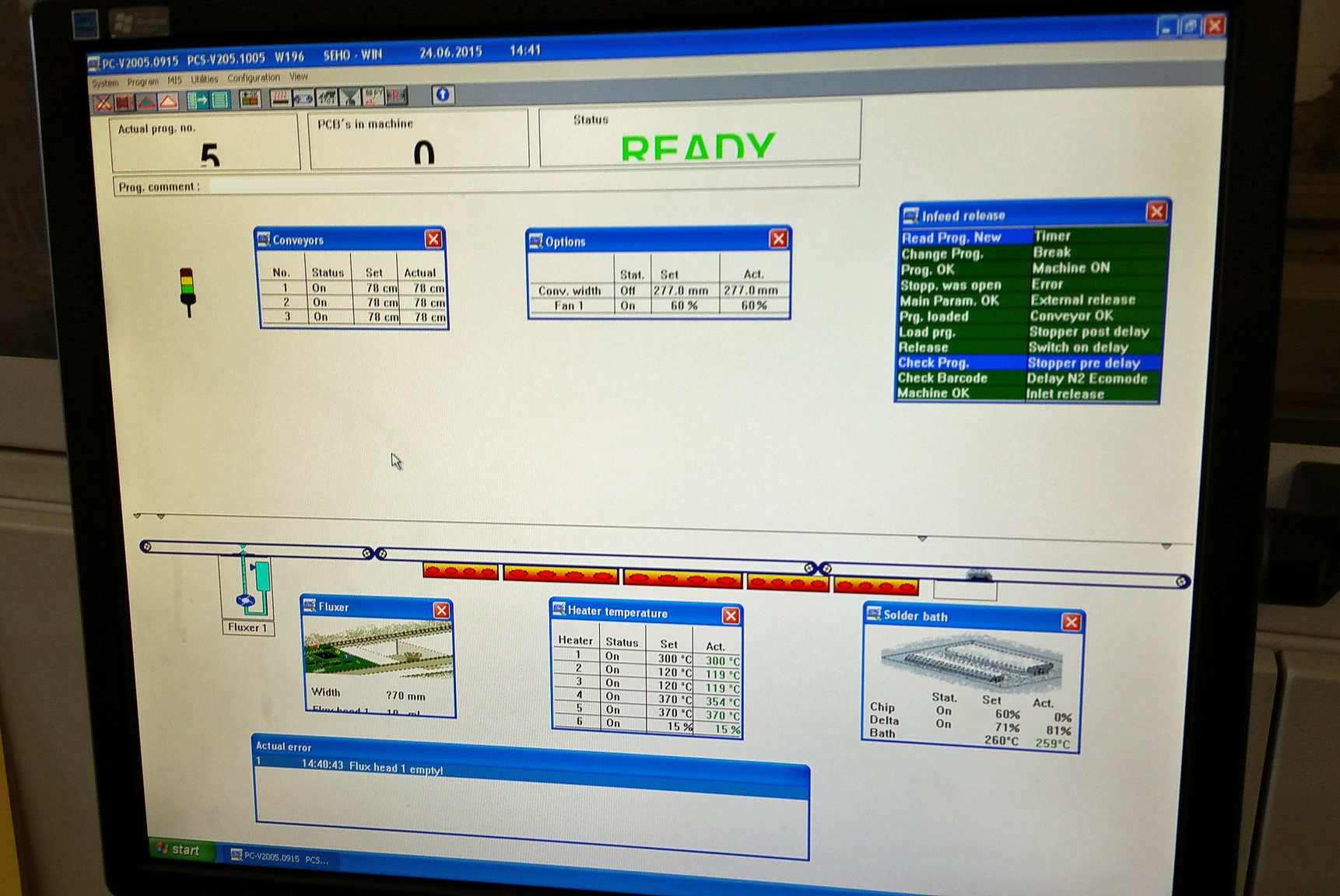

Windows XP based software program

208V, 3 Phase

2005 vintage.

SEHO PowerWave 8250 is a reliable and high-precision pcb solder machine designed for high-volume production of printed circuit boards (PCB). It is equipped with a modern and innovative 4-axis robotic equipment that ensures fast and precise production flow of PCBs. The machine offers direct drive technology for greater precision and higher productivity. The unique feature of this machine is its fast and precise 4-axis robotic system. The robotic unit can accurately pick and place components at any angle, ensuring better accuracy and reliability. The direct drive technology provides better control of the solder joint process. The software is very advanced and features a wide range of automated processes, such as component selection, placement, programming and production of printed circuit boards. PowerWave 8250 has a maximum temperature of 350°C and an automatic solder feed rate of 23 cm/s. The machine is suitable for a wide range of components, as it is capable of soldering 0.25mm to 0.5mm components with ease. The machine is designed to work with various types of boards and can easily handle multi-layer boards up to 8 layers with a minimum line width of 0.2mm. SEHO PowerWave 8250 can significantly save your time and money, by providing automatic reflow soldering with minimal human intervention. This machine also lets you process multiple operations quickly and accurately, such as selective soldering, soldering of surface mount components, wave soldering of BGA components, and through hole components. In Conclusion, PowerWave 8250 offers a reliable and fast solution for mass production of printed circuit boards. With its advanced 4-axis robotic machine, direct drive technology and automated processes, it is an ideal solution for high volume production, while ensuring high quality pieces.

There are no reviews yet