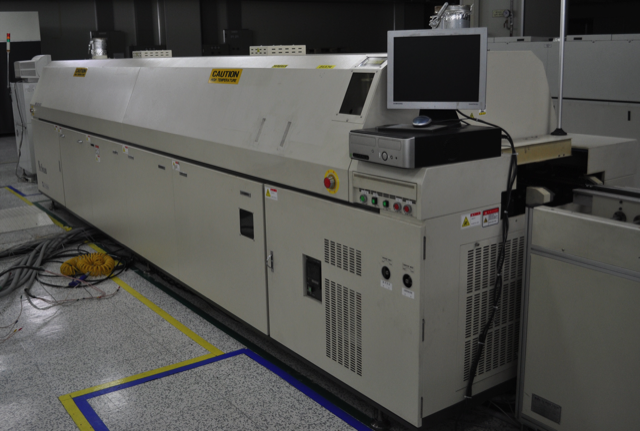

Used TSM NIS-K20-82C #141873 for sale

URL successfully copied!

Tap to zoom

TSM NIS-K20-82C is an automated pick-and-place soldering and inspection machine designed for the production of printed circuit boards (PCBs). This versatile machine uses and multiple, fine-tipped, conveyorized applicators that move parts from component traces, to component placement, to solder joints, and then inspects the entire board for quality. It is capable of producing complex and complex boards with high accuracy and precision, making it ideal for mass production of a variety of types of PCBs. The outside of the machine has a robotic arm with a set of swivel joints that enable the operator to adjust the length of the conveyor chain, allowing it to work with different size parts. The arm also features an automated component placement equipment, a component positioning tool, and a component placement sensor. The robot arm is connected to a separate control unit, which can be interconnected to the computer and the machine's database. Inside the machine, the PCB travels on an infeed conveyor system, which allows the application of components with accuracy and repeatability. The unit is based on an integrated conveyor, a conveyor belt, a synchronization machine, and a swivel joint for easy access to the entire board. The conveyor tool moves the board to a rotating application station, where the parts are placed on the PWB with a tweezerlike tool, and the robotic arm applies the solder paste and installs the components. At the exit of the machine, the boards are inspected for quality and accuracy, and the results are recorded. A built-in image detection asset is used to inspect the PCBs for minute defects. The machine can also be used for visual inspection and defect analysis. To ensure the boards meet the required standards, the machine includes several control systems such as, A/D conversion, temperature control and error correction. Additionally, the machine is equipped with a specialized laser and trace masker to help detect and repair any imperfections, if necessary. NIS-K20-82C, is a state-of-the-art machine that can produce high-quality, complex PCBs with accuracy and precision. It is ideal for high-demand production systems, as well as applications requiring tight tolerances and high up-time. The machine's features include robust construction and dependability, fast cycle times, and an onboard monitoring model to ensure accuracy and repeatability. Its fully automated nature makes it ideal for automated production lines, making it an efficient solution for producing PCBs quickly and accurately.

There are no reviews yet