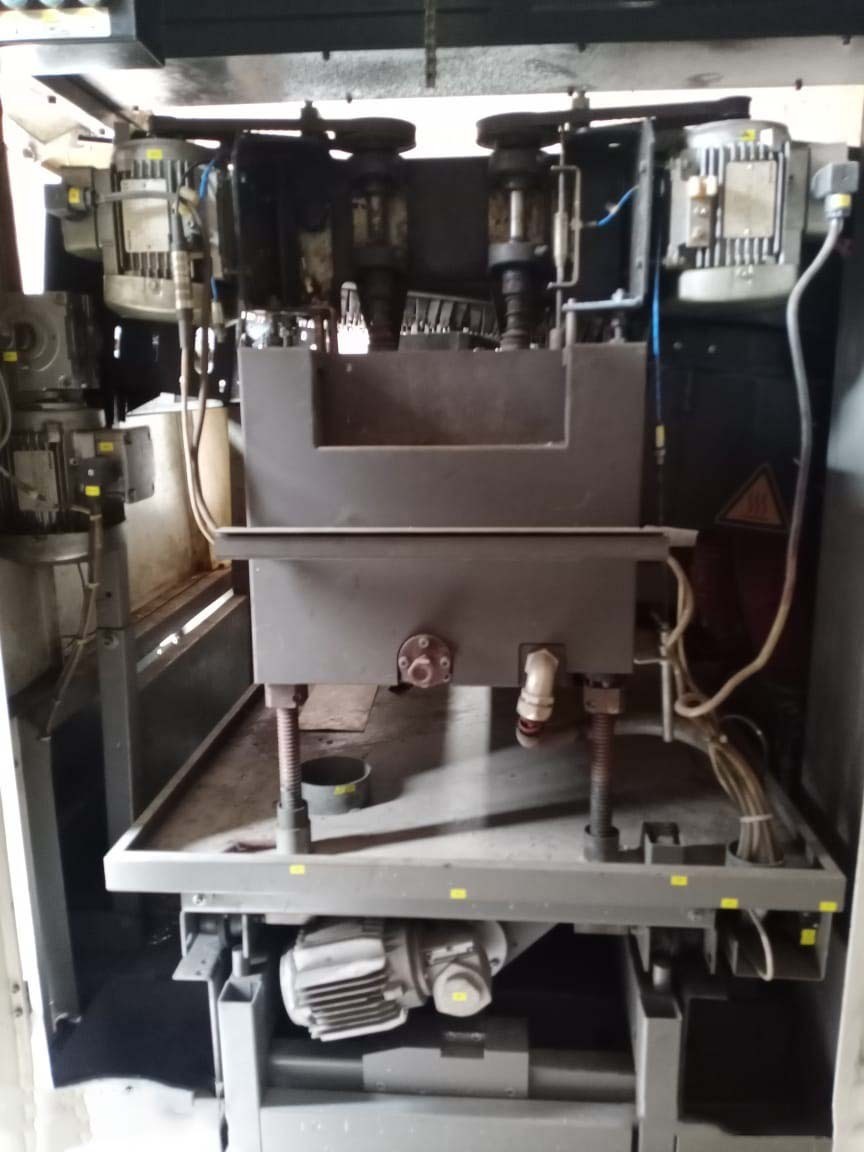

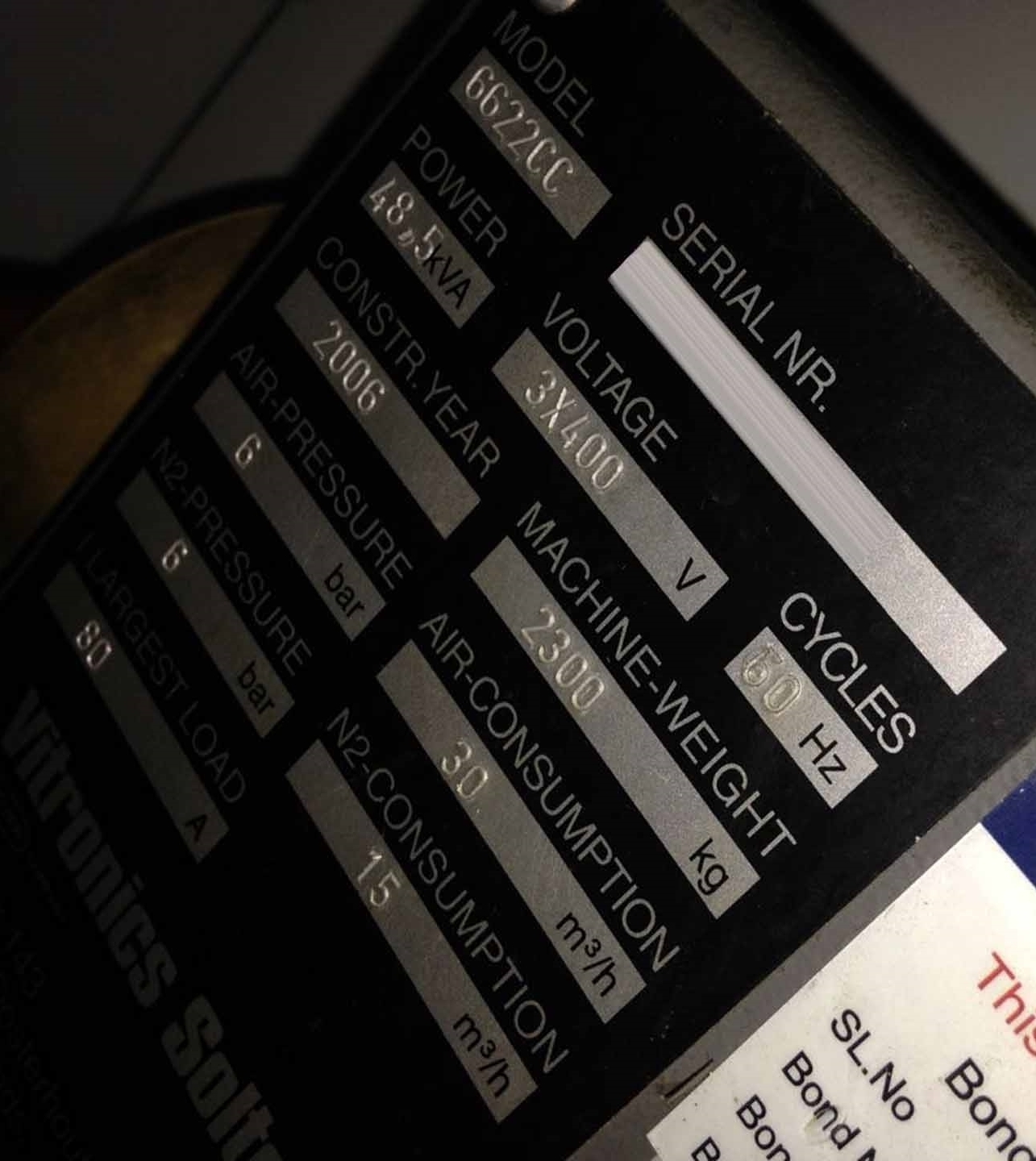

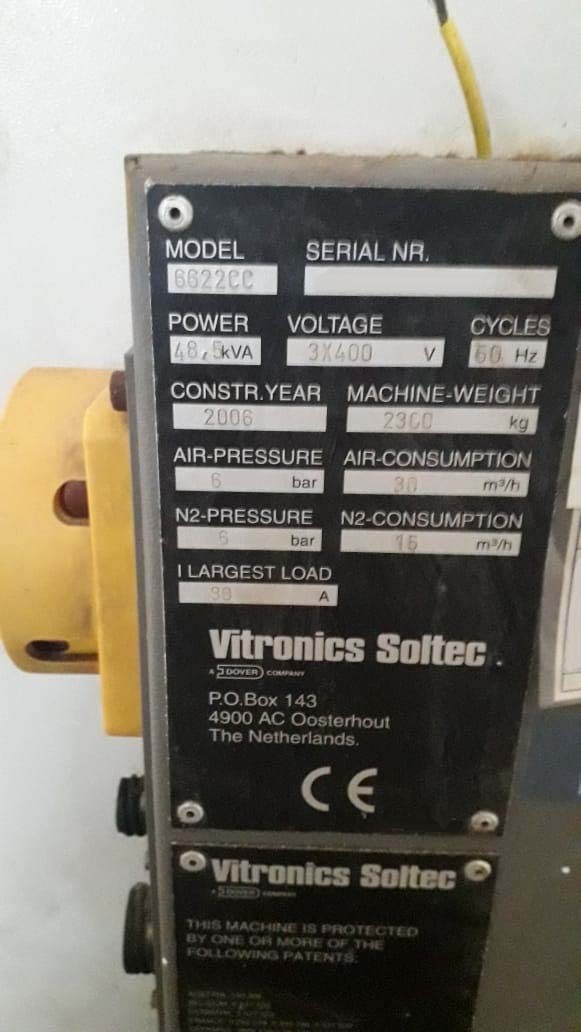

Used VITRONICS SOLTEC 6622 CC #9222346 for sale

URL successfully copied!

Tap to zoom

ID: 9222346

Vintage: 2006

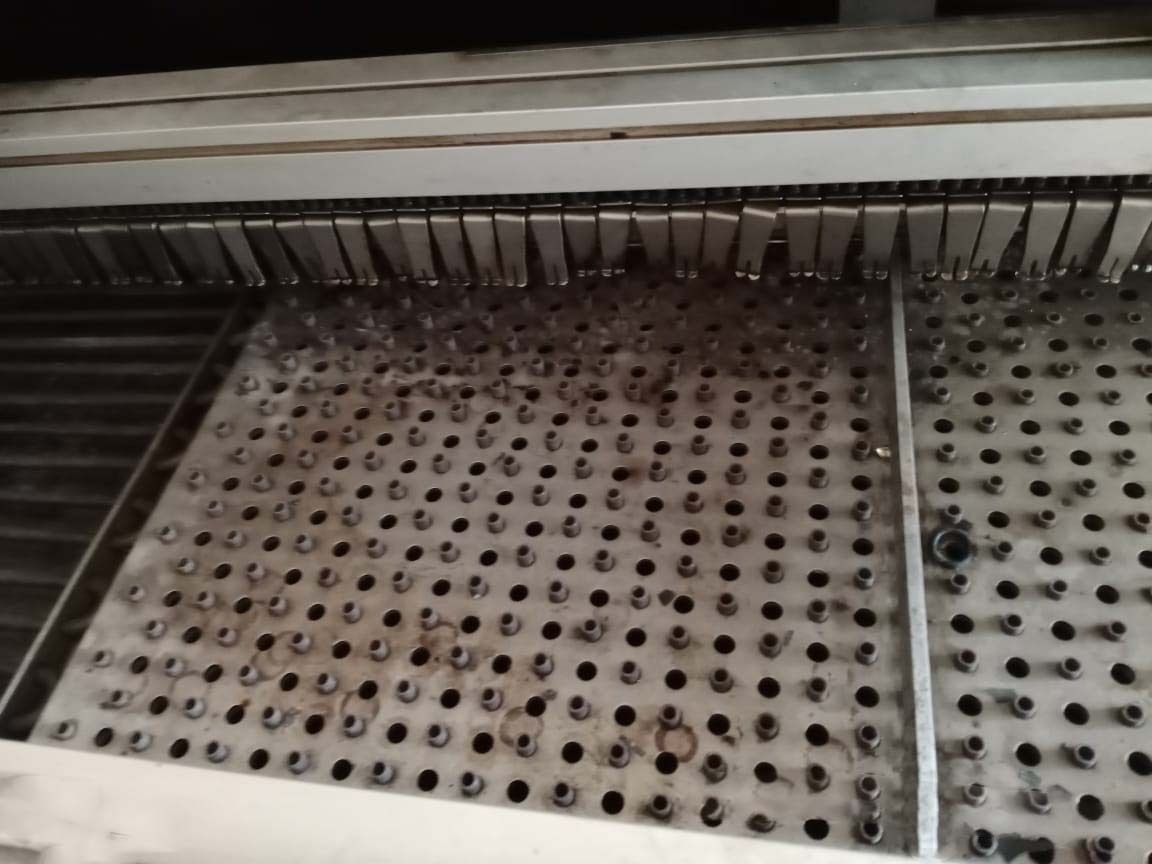

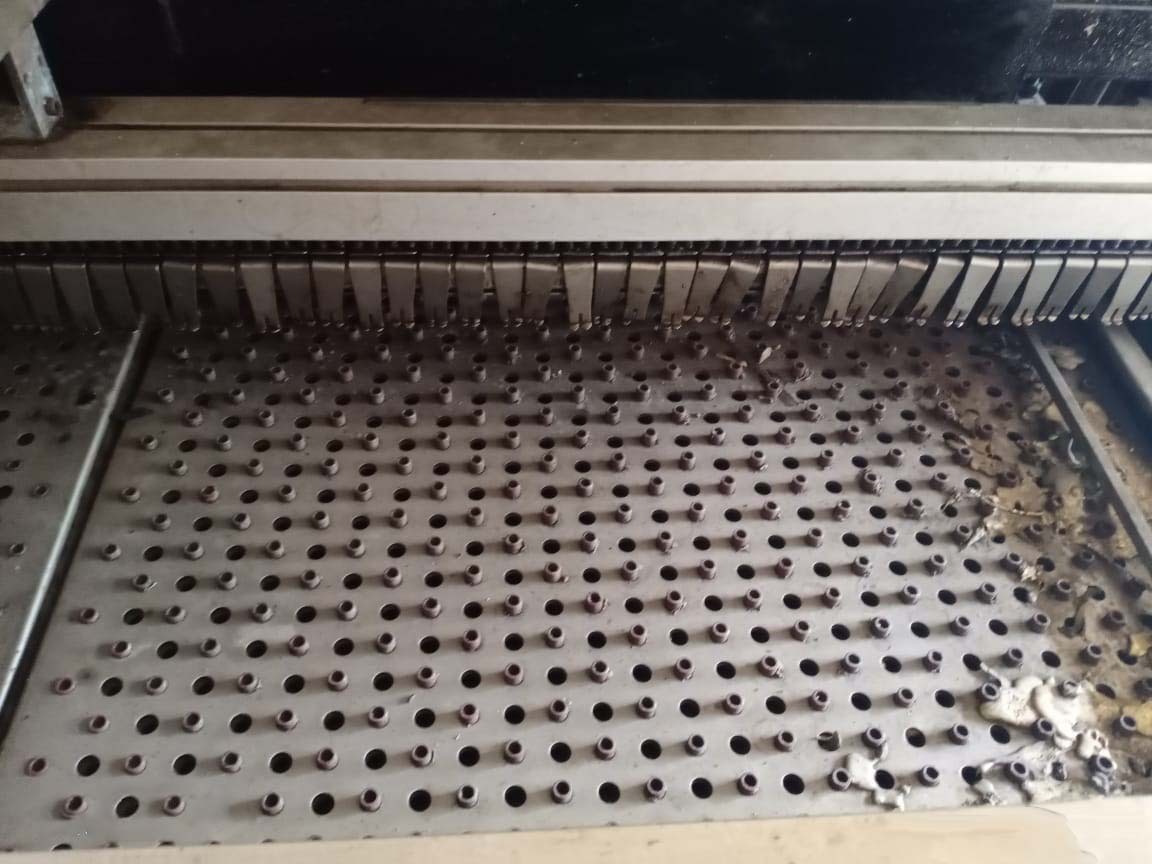

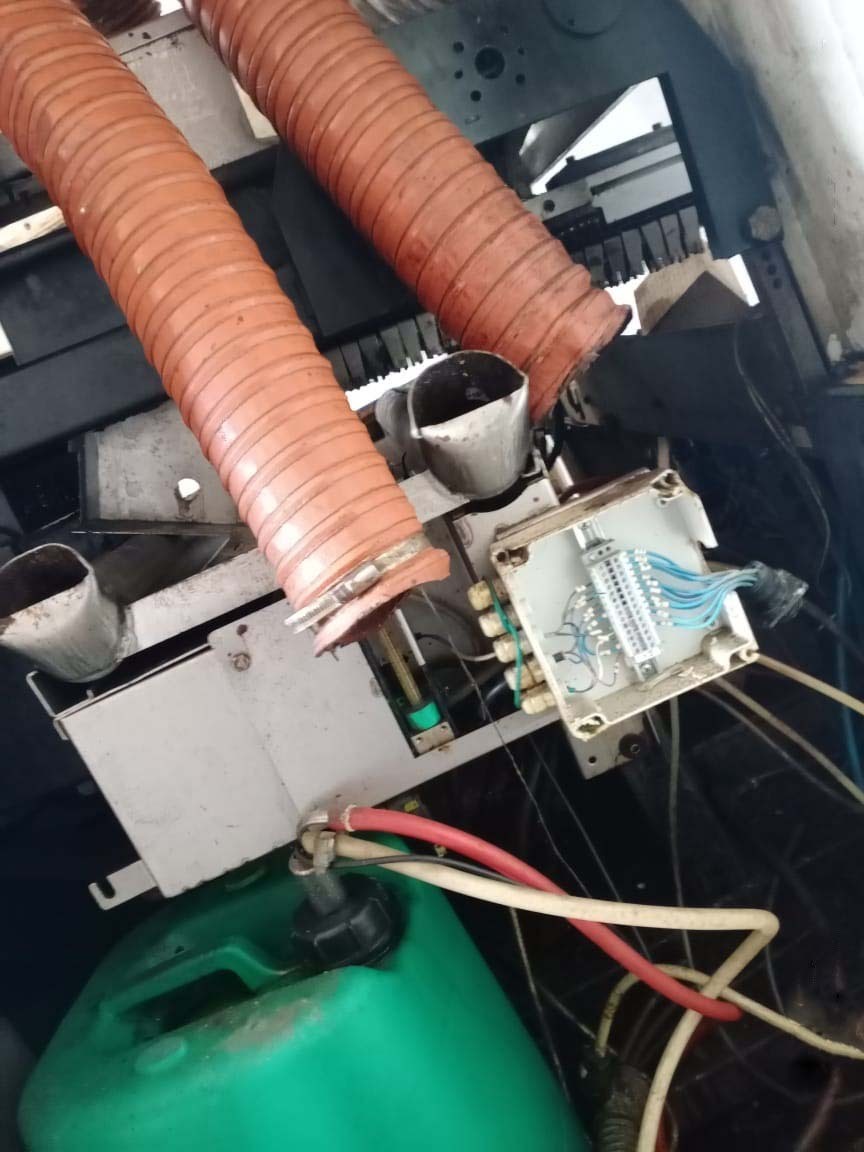

Delta wave soldering machine

Lead free

Loading / Unloading conveyor

2006 vintage.

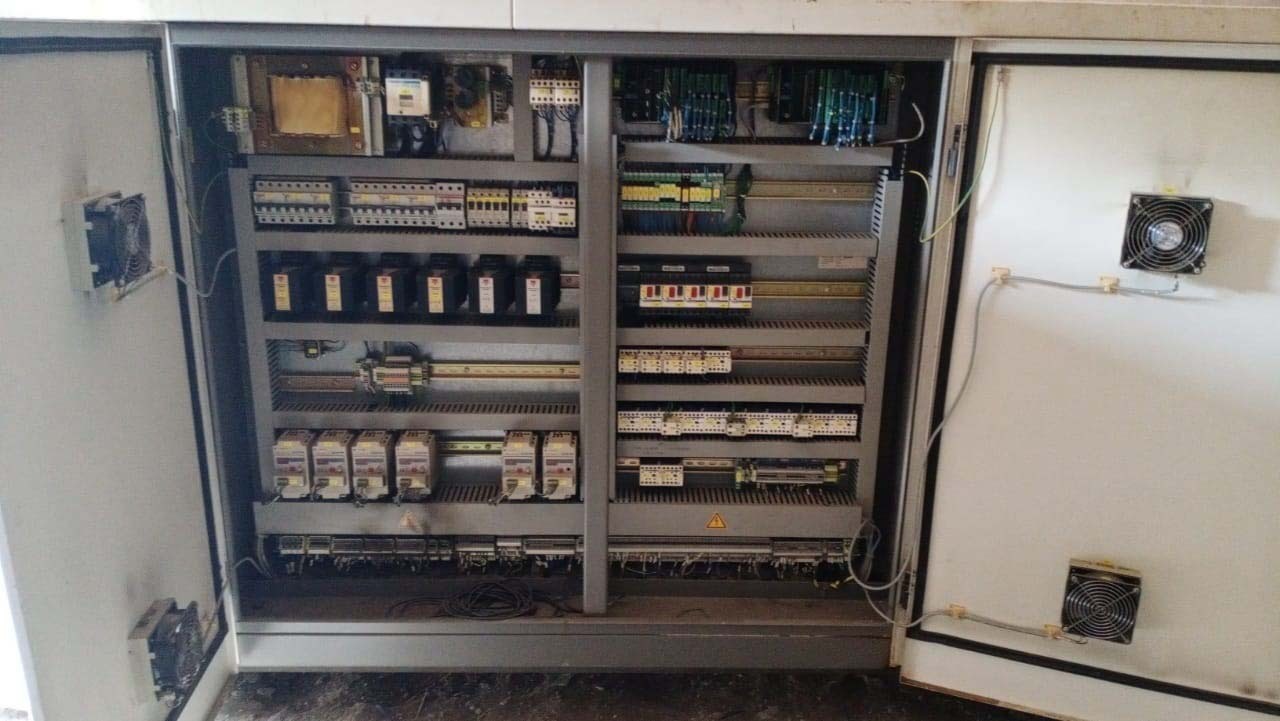

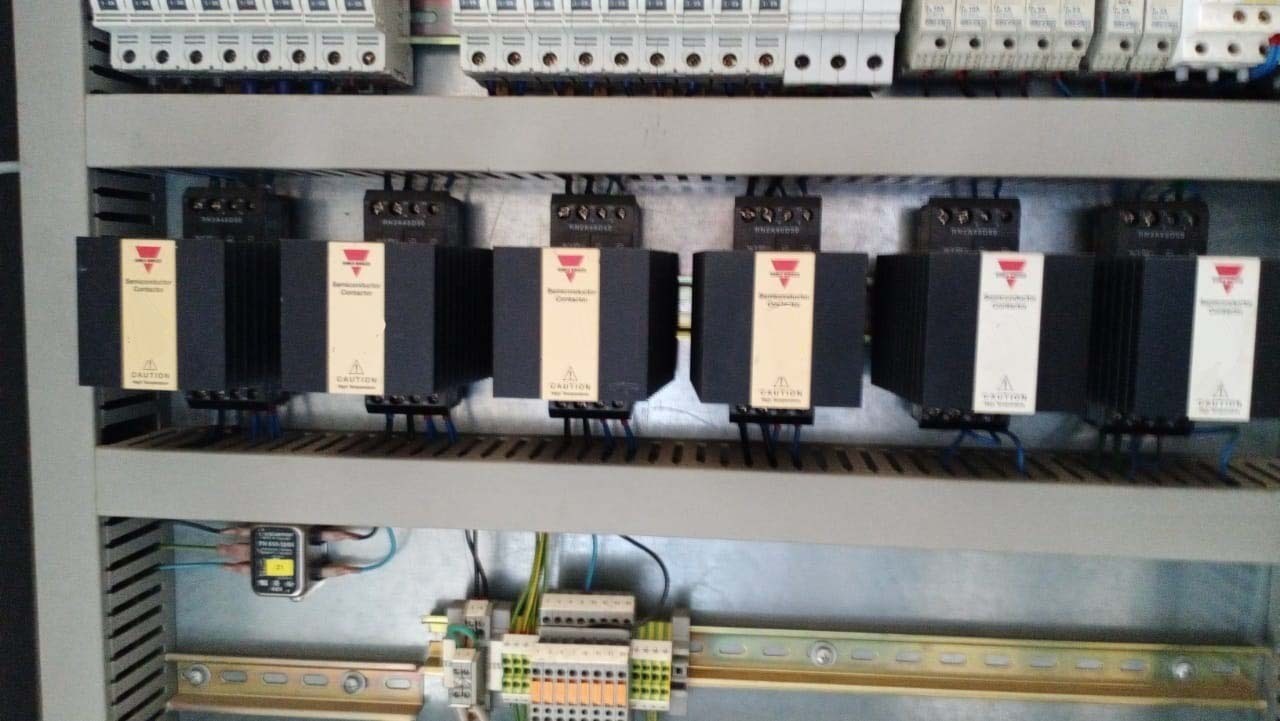

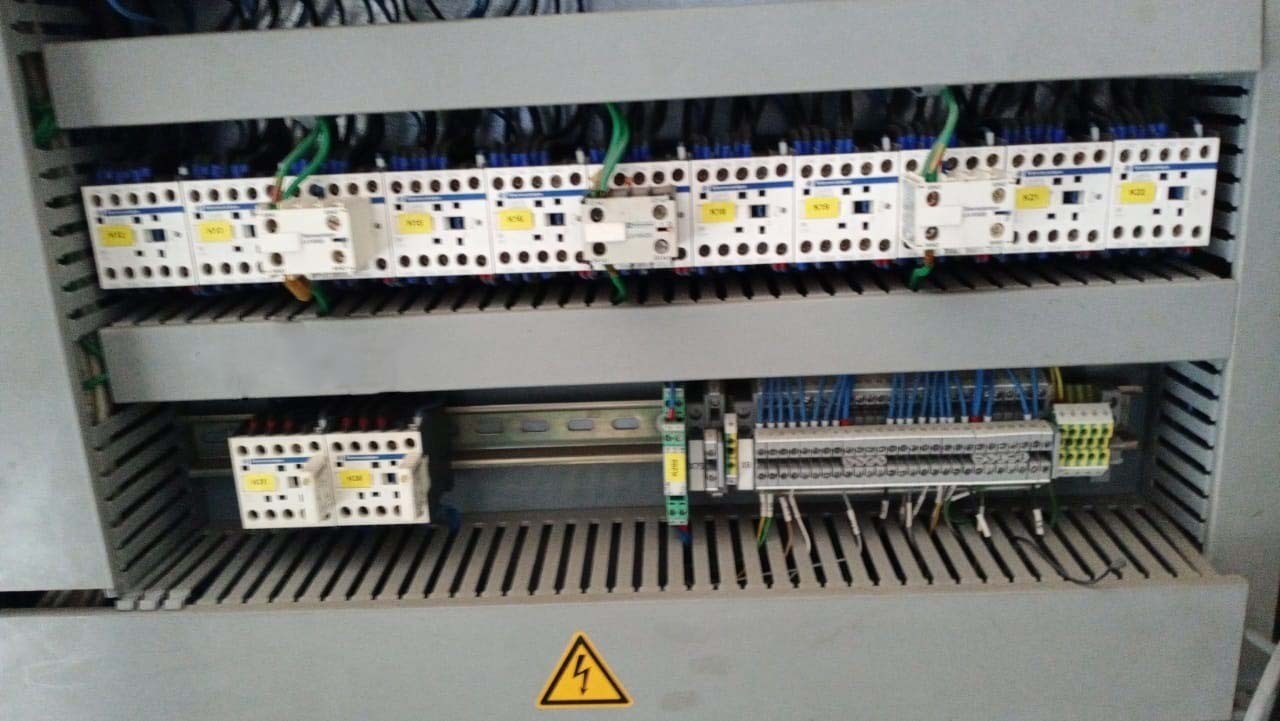

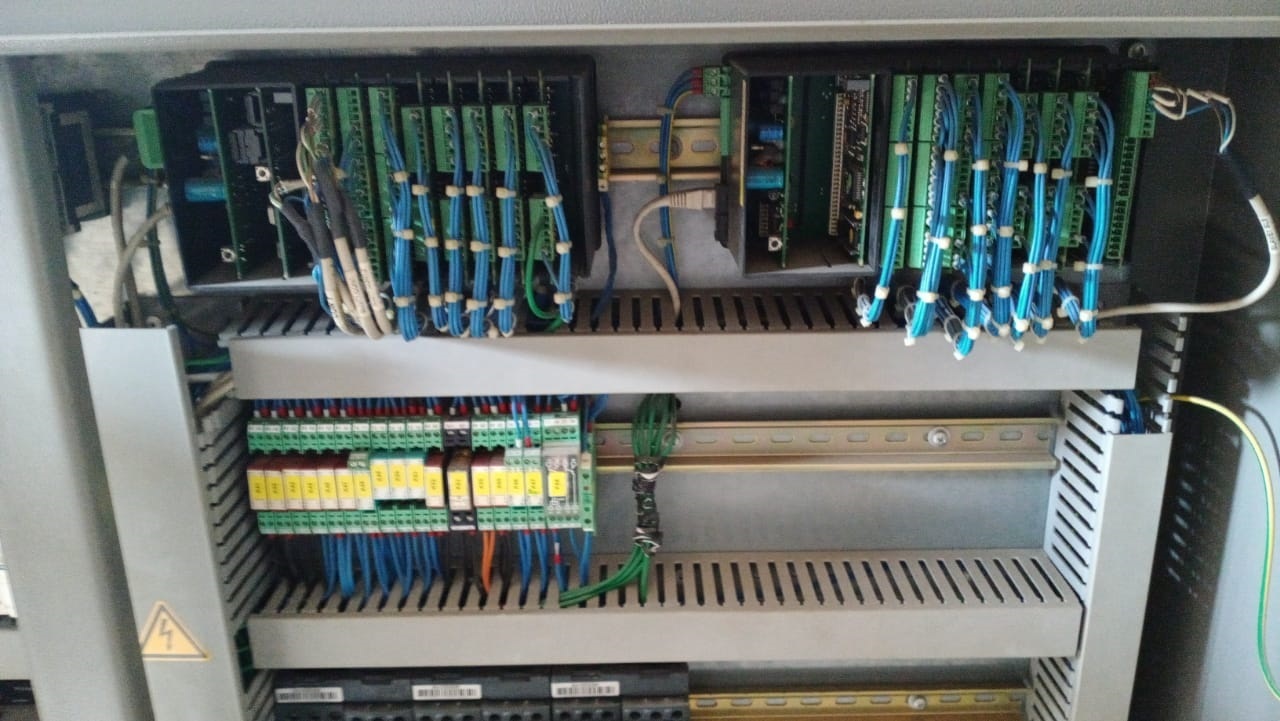

VITRONICS SOLTEC 6622 CC is a precision soldering machine designed for electronic manufacturing applications. This soldering machine is designed for use in the assembly of Printed Circuit Boards (PCBs). It is equipped with a high accuracy motorized point-to-point solder equipment and an adjustable platform height, enabling flexible soldering of multi-dimensional components. VITRONICS SOLTEC 6622CC is capable of easily adapting to meet the different requirements in production due to its versatile program memory and modular design. Feature highlights of SOLTEC 6622CC include a circular teaching system, self-diagnostic program, display panel for real-time status/process deviations, wave soldering program, preheat zone adjustment, dual wave generator, SMEMA interface and open unit architecture. The programmed control machine allows the production to be efficient and reduce costs of labor providing all-round productivity. VITRONICS SOLTEC SOLTEC 6622CC uses the dual wave generator to increase the efficiency of the soldering process; a convection preheat zone uniformly preheats components and solder wave, preventing component cracking of delicate parts, and provides de-wetting of solder joints. The adjustable platform height makes it possible for operators to make changes to the machine, even if the parts on the PCB are of varying sizes and heights. The machine is equipped with an optimized air flow tool that ensures uniform airflow and cooling within the cabin, providing a safe environment for the operator and the components. Additionally, a self-diagnostic program helps detect any anomalies with the machine, allowing quick resolution of potential problems to ensure maximum productivity. To ensure the accuracy of soldering processes, 6622CC features an intelligent circular teaching asset, SMEMA interface with rest interface (RI) and open model architecture. The circular teaching equipment automatically adjusts the width of the laser beam according to the size and shape of the component and the type of PCB, to ensure accuracy and reduce the possibility of errors. The SMEMA interface allows 6622 CC to be integrated into an automated system, helping the process become more efficient and enhance production throughput. The open unit architecture allows for the addition of new software and programs, like PC board layout and process control logic, to be added at any time without having to purchase additional hardware. Finally, VITRONICS SOLTEC 6622 CC is equipped with a wide array of safety features, including: E-stop and safety light curtains for operator safety, foot pedal activation for additional operator protection, and interlock features to prevent unauthorized access to the machine. This cost-effective machine is ideal for a wide range of production requirements, providing the accuracy and reliability needed for high-quality production.

There are no reviews yet