Used VITRONICS SOLTEC 6721 CC #9036564 for sale

URL successfully copied!

Tap to zoom

ID: 9036564

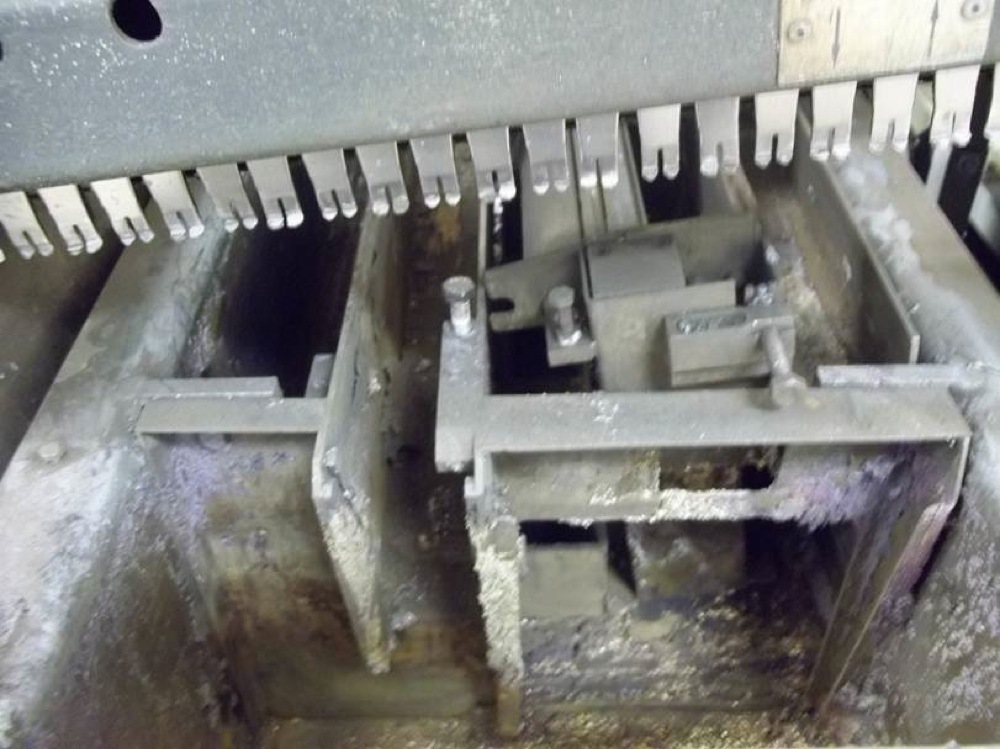

Wave soldering machine

Leaded

Includes:

(2) Preheats

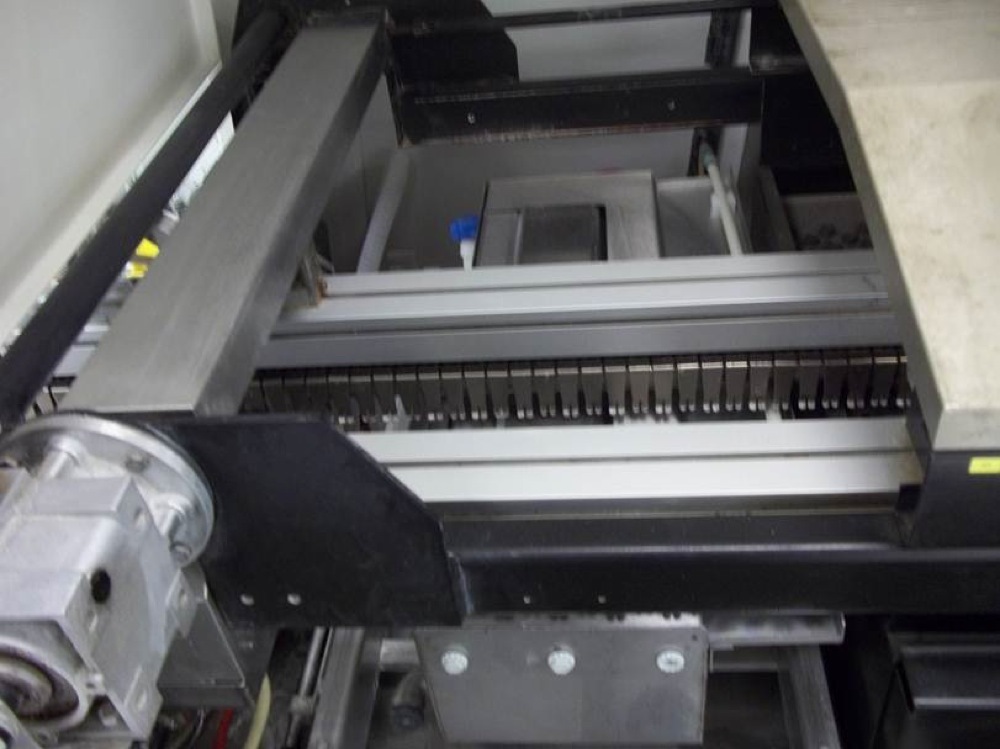

Automatic rail width adjust

Automatic PCB tracking

Fluxer air knife on/off

Solder pot transition (from idle rpm to run rpm)

Smart wave on/off

PCB dropped in machine alarm

PCB counter

Heavy duty transport fingers (50% L-shape, 50% V-shape)

Motorized pot height and rollout

Convection

Calrod

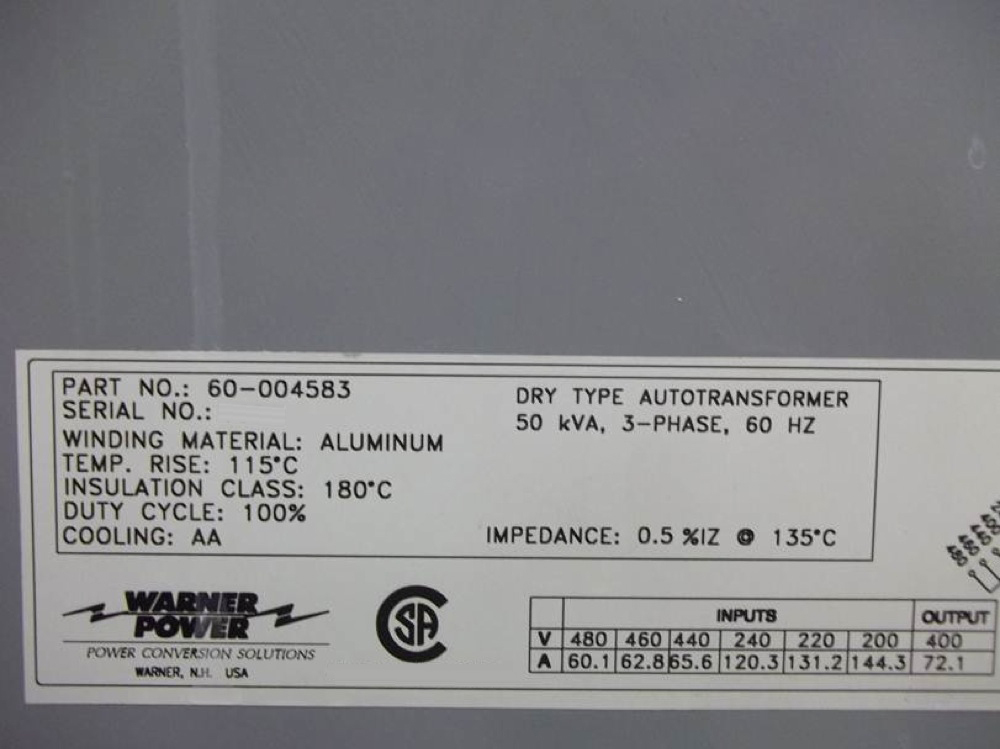

Transformer: 200/480VAC to 400VAC

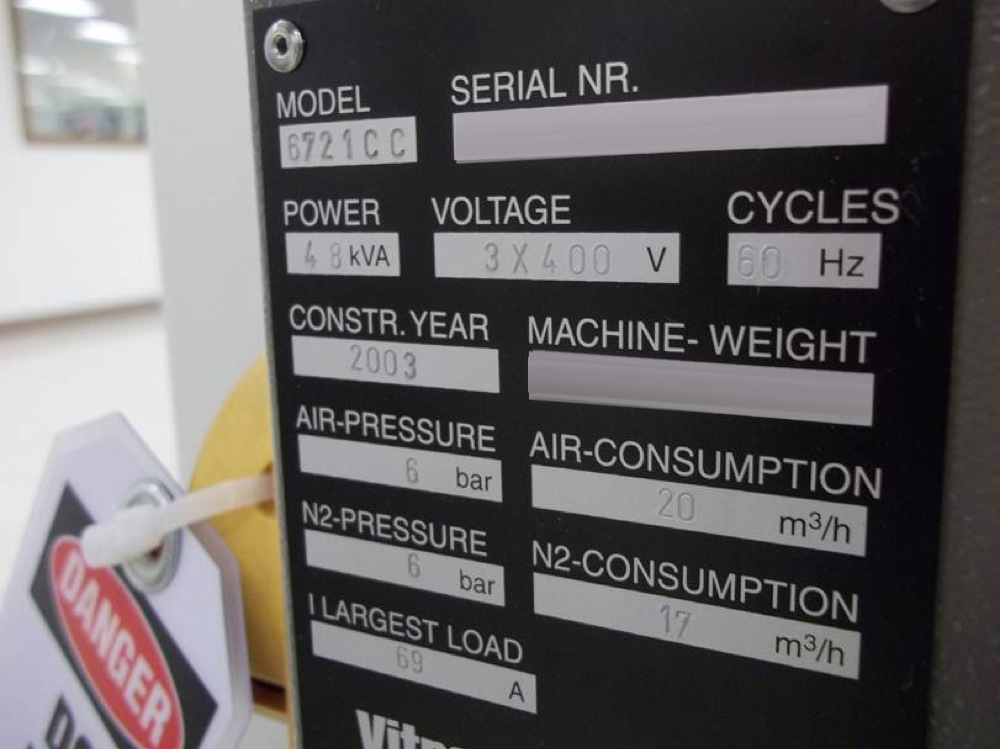

Air pressure: 6 bar

Air consumption: 20 m3/h

N2 pressure: 6 bar

N2 consumption: 17 m3/h

Largest load: 60 A

48 kVA, 3x400 V, 60 Hz

2003 vintage.

VITRONICS SOLTEC 6721 CC is an advanced semi-automatic PCB Solder machine suitable for use in both production and prototyping. This machine offers a flexible solution to a wide range of soldering needs and is capable of processing both single- and double-sided boards quickly and efficiently. 6721 CC features an advanced vision-based equipment, which automatically detects board topology and board components for accurate soldering. The vision-based system is capable of detecting both BGA and CSP pads, as well as SMD components. Additionally, the unit is capable of automatically adjusting its process parameters, including the temperature range, to ensure optimal soldering performance. Furthermore, the vision machine is capable of recognizing any irregular board topologies, such as ground-level components, which can get in the way of efficient soldering. This solder machine also includes an automated fiducial recognition tool, which helps to ensure that all PCBs are accurately registered and set in place prior to the soldering process. This asset eliminates user errors and provides a reliable soldering process. Furthermore, the machine is equipped with a powerful NOx-free hot-air model, which provides precise soldering temperature and proper soldering of sensitive components. In addition, VITRONICS SOLTEC 6721 CC is equipped with an advanced open-loop process control equipment, which provides users with full control over the soldering process, and ensures that all PCBs are properly soldered without the risk of over-saturation or under-saturation of solder joints. Furthermore, the process control system keeps track of temperature readings and uses graphical temperature profiles for precise and consistent soldering results. Finally, 6721 CC features a user-friendly touchscreen interface, which is intuitive and simple to use. This interface enables customers to quickly set up the soldering process, adjust the temperature range, and monitor the soldering process. Additionally, this machine is compact enough to fit into any workspace and is designed to be energy efficient, ensuring that users maintain a low overhead. VITRONICS SOLTEC 6721 CC is an advanced solution for PCB soldering, providing users with precise and consistent soldering results. This machine is ideal for anyone looking for a flexible and reliable soldering process. By combining its automated vision-based unit, fiducial recognition, open-loop process control, NOx-free hot-air machine, and user-friendly touchscreen interface, this solder machine is capable of meeting the needs of users from both production and prototyping environments.

There are no reviews yet