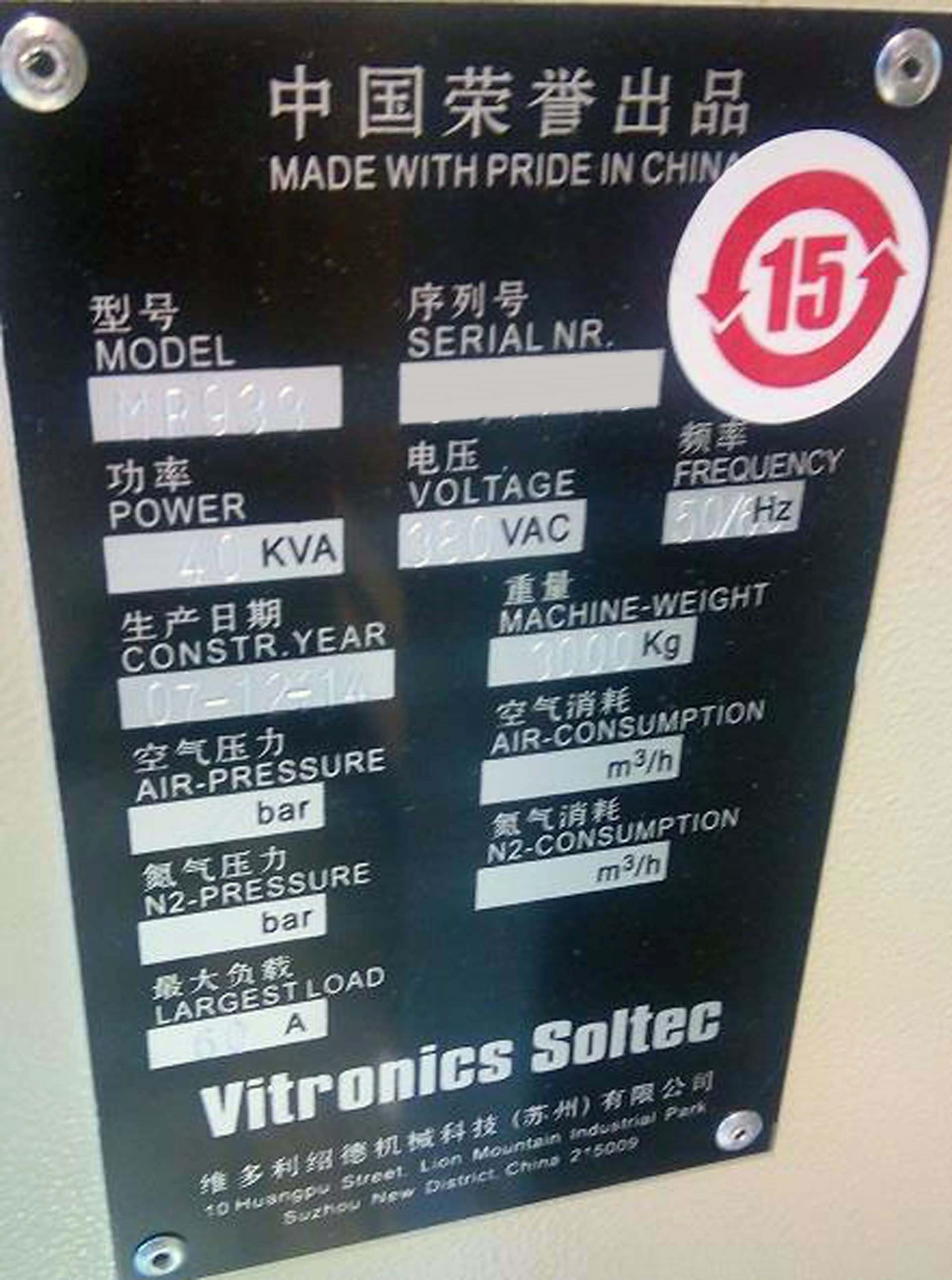

Used VITRONICS SOLTEC MR 933 #9240668 for sale

URL successfully copied!

Tap to zoom

ID: 9240668

Vintage: 2007

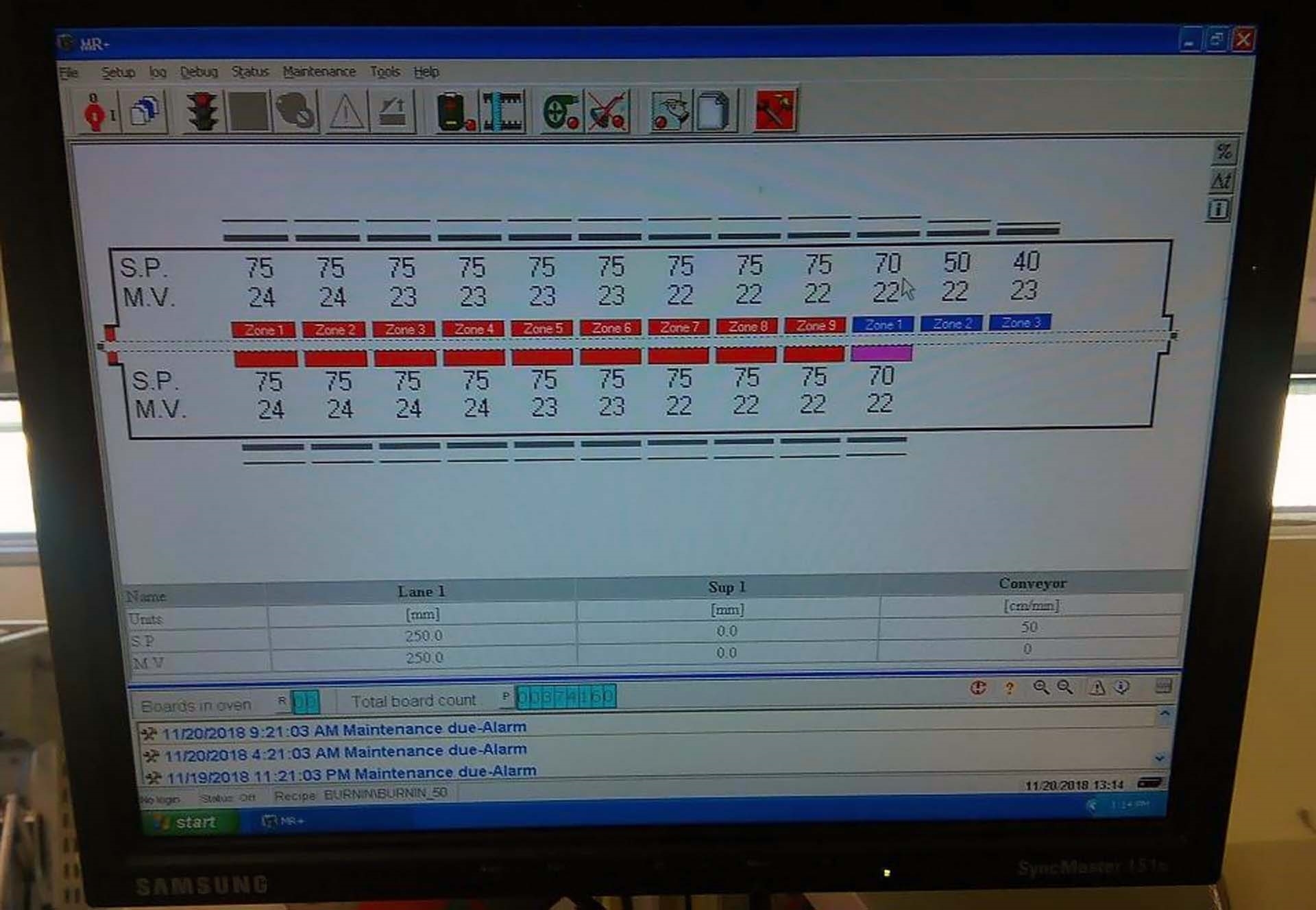

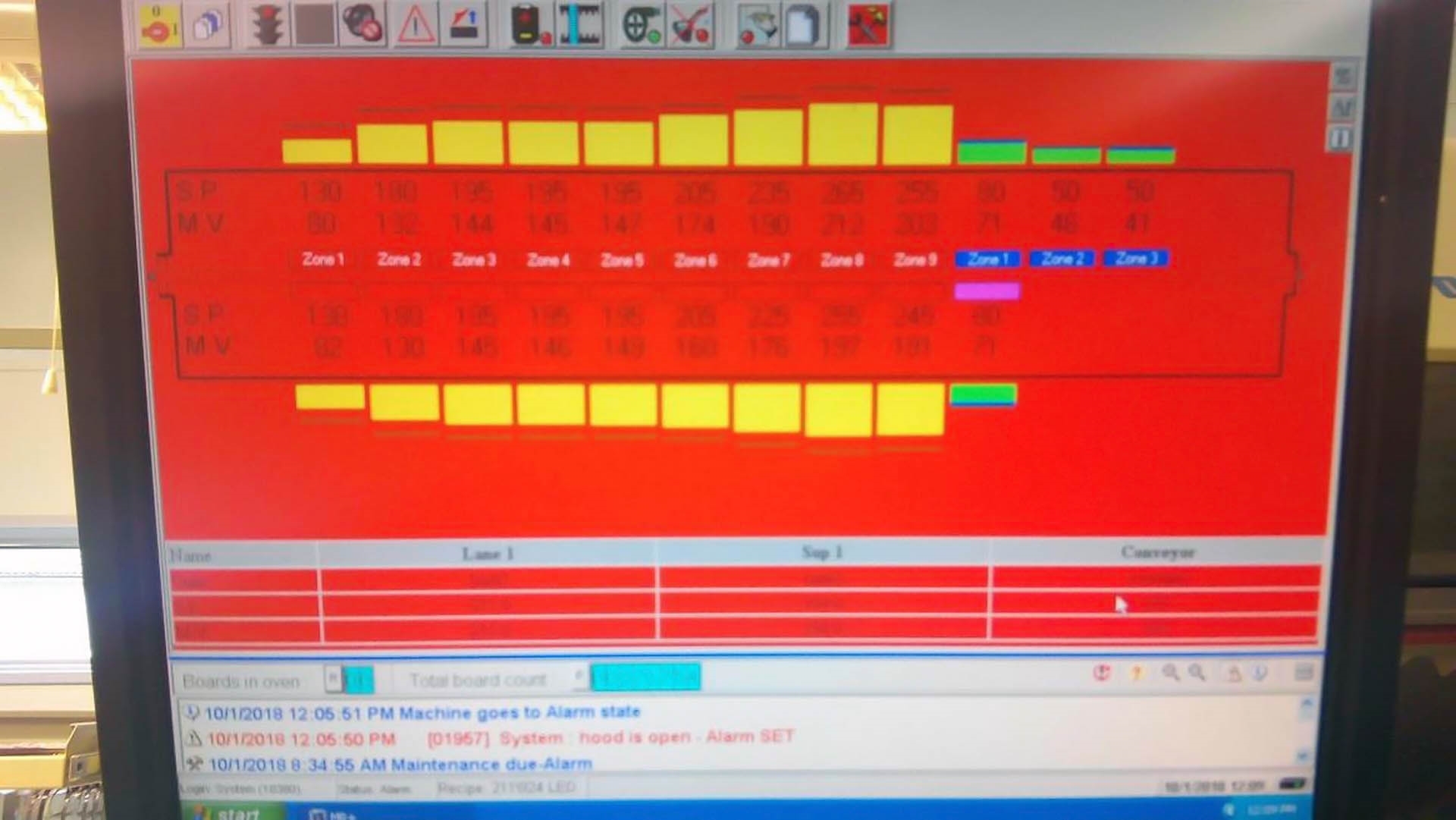

Reflow oven

(9) Heating zones

(3) Cooling zones

Board center support

Auto chain lubrication

Flux trap

2007 vintage.

VITRONICS SOLTEC MR 933 is an automated pin feeder pcb solder machine that offers exceptional accuracy and repeatability. This solder machine is highly automated and features advanced technology enabling precise difference in temperature regulation. It combines multizone pre-heat, the use of a multitude of different solder alloys, and integrated fluxing systems to ensure optimum results. MR 933 features an adjustable pinout for both long and short pin pitch components. Its adjustable pins offer high-accuracy placement of components in the PCB. Furthermore, its adjustable pressure in the squeegee can be used to reduce slippage of pin components. Additionally, it has adjustable cut angles which allow accurate cutting angles when trimming excess solder. This ensures high-precision soldering for optimum performance and reliability. With its top-of-the-line technology, VITRONICS SOLTEC MR 933 delivers superior quality soldering with the finest precision. It also offers repeatability owing to its advanced feeder technology with the ability to detect component size, type, and quantity for easy placement. This allows for efficient process automation, reducing the time spent on soldering. MR 933 is equipped with an advanced integrated flux dispensing equipment that ensures precise flux dispensing and is also easily programmed up to 160 parameters. The temperature control technology also enables efficient repeatability in soldering temperatures. Additionally, the advanced tolerances make it possible to work with very small components along with larger ones without compromising on the production volume. VITRONICS SOLTEC MR 933 also comes with a comprehensive monitoring system to help with the maintenance of the machine. All critical parameters are constantly monitored and instantly reported, if any warning signs are detected. The comprehensive monitoring unit helps operators optimize the machine's performance and prevent potential breakdowns of the machine, saving time and money. Overall, MR 933 offers robust and precise soldering with advanced accuracy and repeatability. The integrated flux dispenser machine and the temperature control technology enable efficient repeatability in soldering parameters. The monitoring tool ensures the machine can be maintained correctly, helping to increase productivity and prevent potential breakdowns.

There are no reviews yet