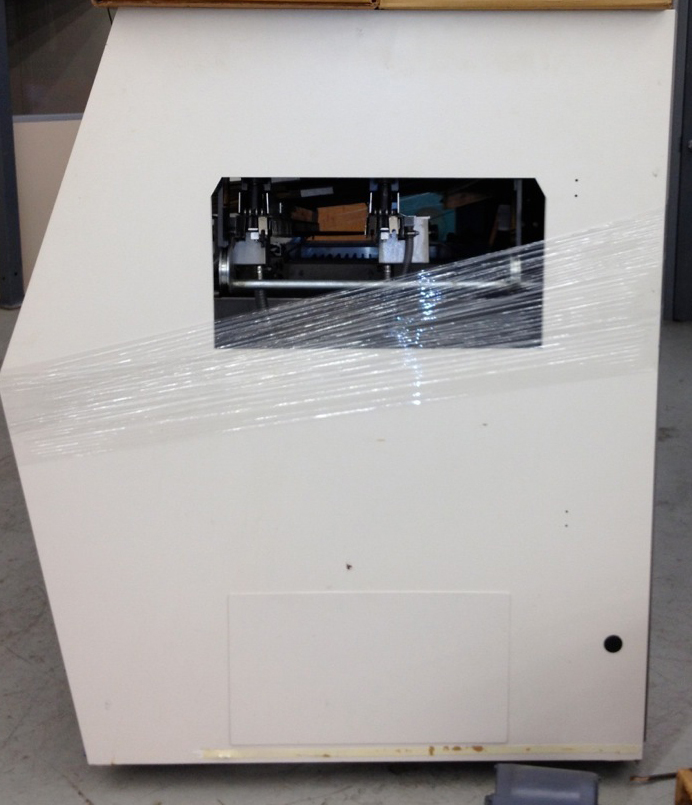

Used VITRONICS SOLTEC Prisma Wave #9017874 for sale

URL successfully copied!

Tap to zoom

VITRONICS SOLTEC Prisma Wave PCB solder machine is a state-of-the-art machine designed to meet the specialized needs of the PCB industry. The machine features multiple layers of high-precision optical and electrical engineering and advanced software algorithms to facilitate complex soldering processes. Prisma Wave is tailored for a wide range of PCB applications and is the most advanced platform in PCB final assembly production. VITRONICS SOLTEC Prisma Wave features adaptive vision-guided automated soldering with advanced optical and laser vision systems that help accurately identify and place components on the board. This helps reduce soldering errors caused by operator errors or changes in solder profiles. It also has an intelligent preheat control equipment that allows for better surface preparation for the placement and soldering of components. Prisma Wave's advanced software algorithms automatically detect component locations using intelligent algorithms that adjust for any component placement related errors. The automated soldering system also helps to minimize solder joint defects by optimizing your soldering process through comprehensive rework and redo capabilities. The machine also has a high-quality solder nozzle that helps to ensure accurate solder joint formation and allows for improved yields and lower thermal stresses on components. Additionally, the advanced solder instrument calibration unit ensures accurate and uniform fill geometry for each soldering job. VITRONICS SOLTEC Prisma Wave has an integrated board handling machine that is designed for secure delivery of PCBs and features a non-contact PCB support tool that minimizes vibration. Furthermore, it has a high-speed conveyor asset that automatically conveys PCBs to and from the station, making it fast and efficient. The machine also comes equipped with various safety features. The automated safety systems are designed to continuously monitor machine performance and to shut down the model in case of safety or performance issues. Additionally, the machine features best in class Electrical, Magnetic, and Mechanical safety systems that help reduce the risk of electrical shocks, incorrect component placement, and other errors. Prisma Wave is designed to meet each customer's unique requirements. It is extremely user-friendly, has a wide range of easily customizable features, and employs tooling and software solutions that help reduce assembly time and enable the production of high-quality PCBs.

There are no reviews yet