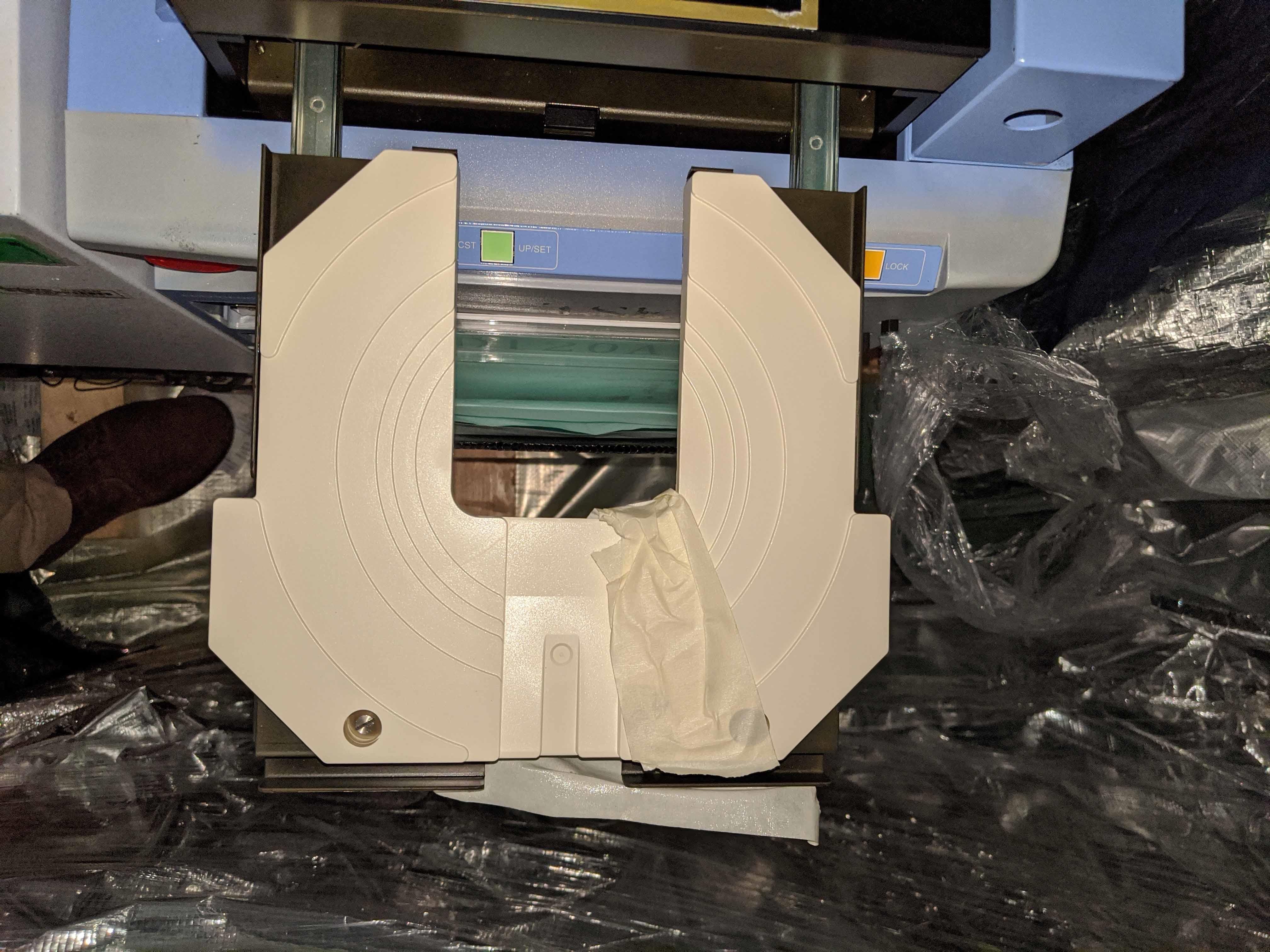

Used ACCRETECH / TSK UF 200 #9283877 for sale

URL successfully copied!

Tap to zoom

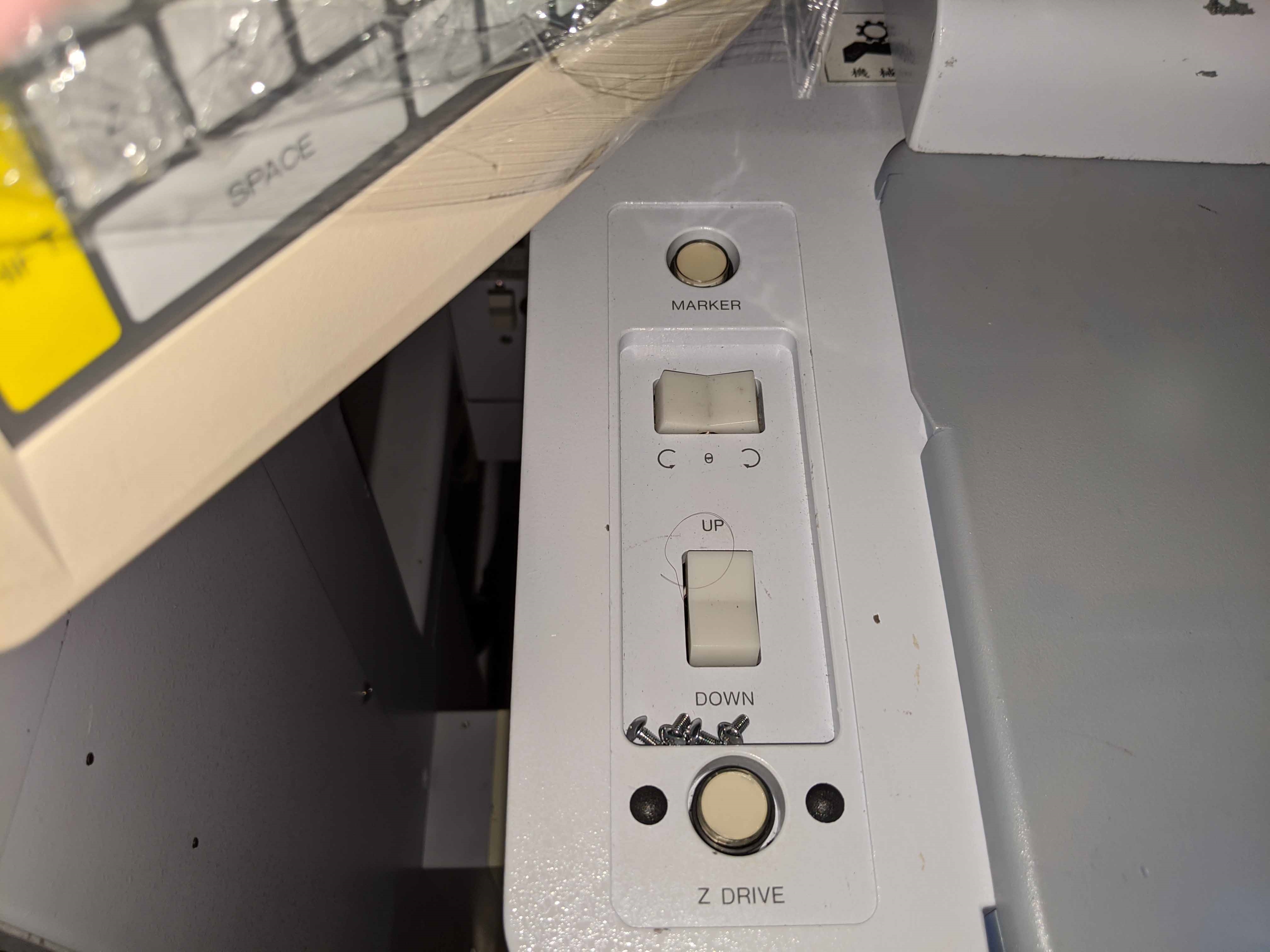

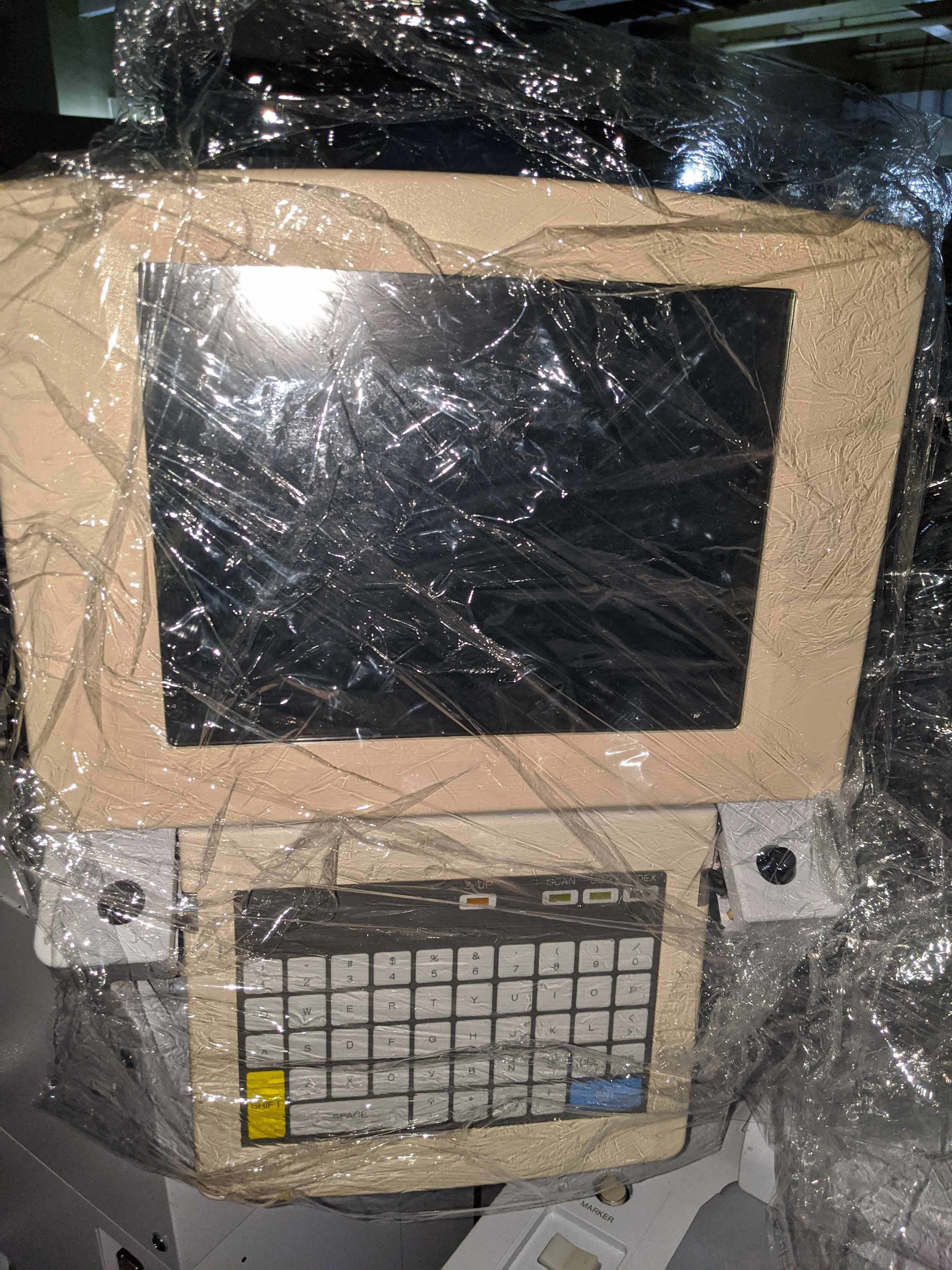

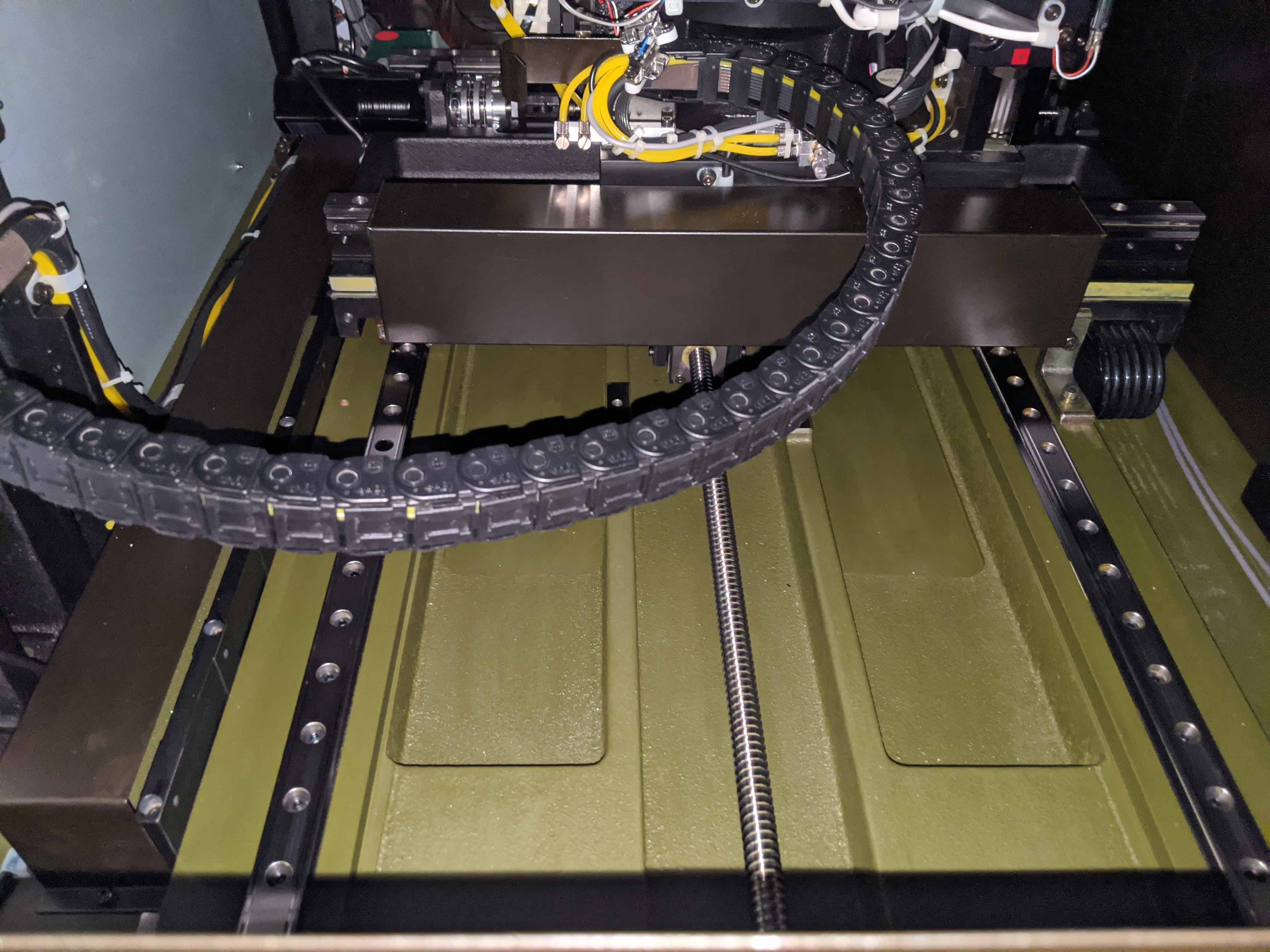

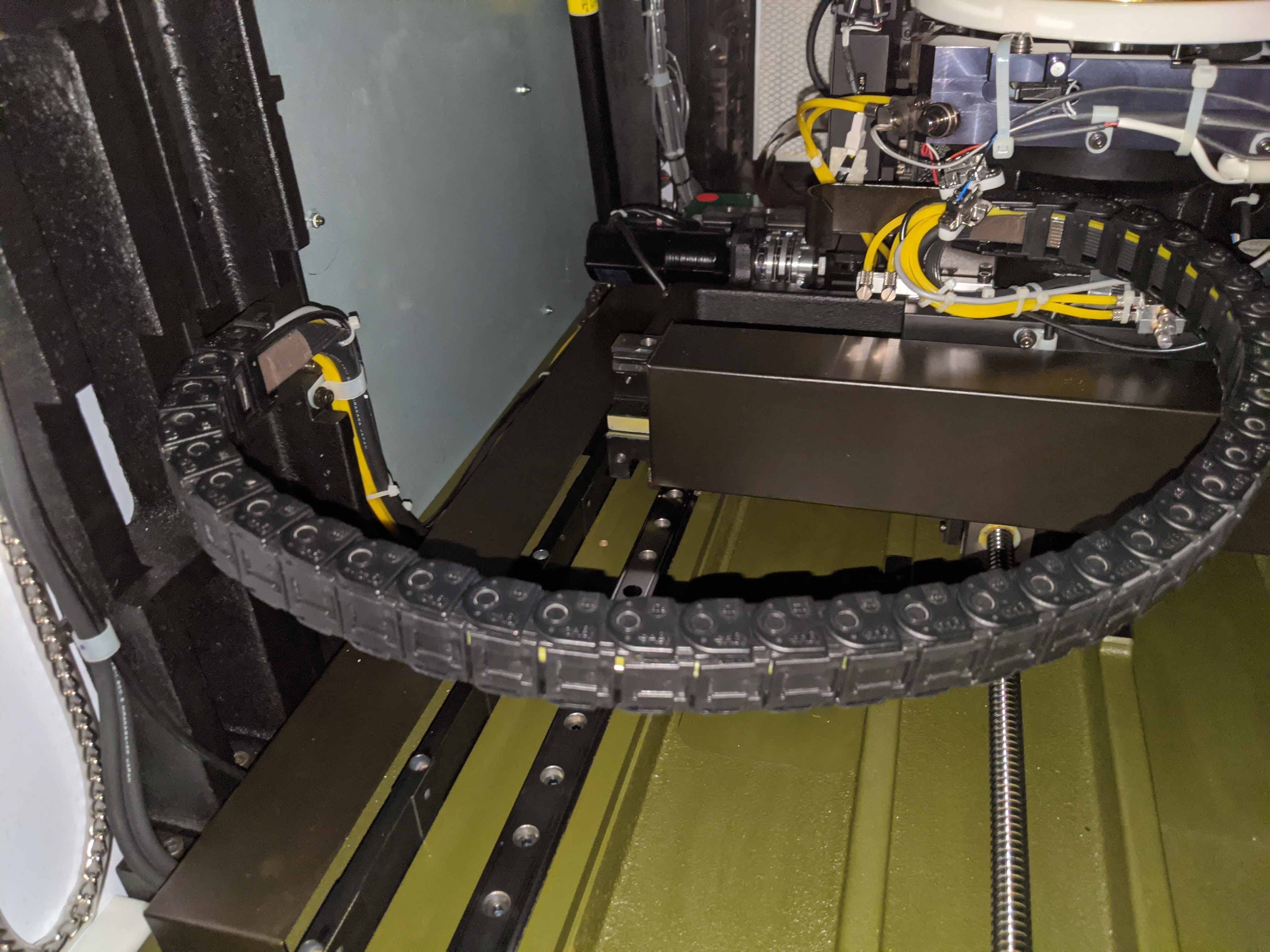

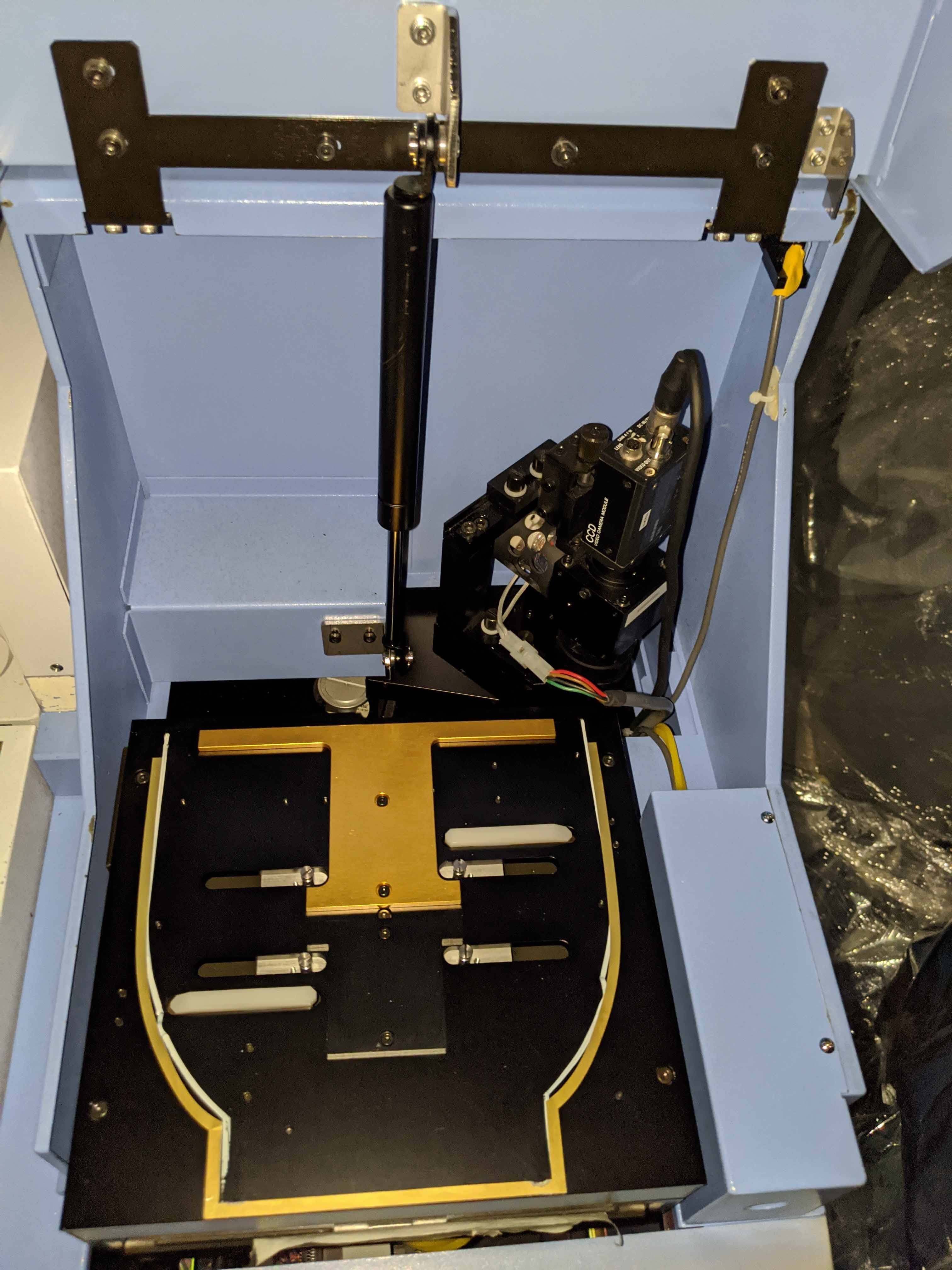

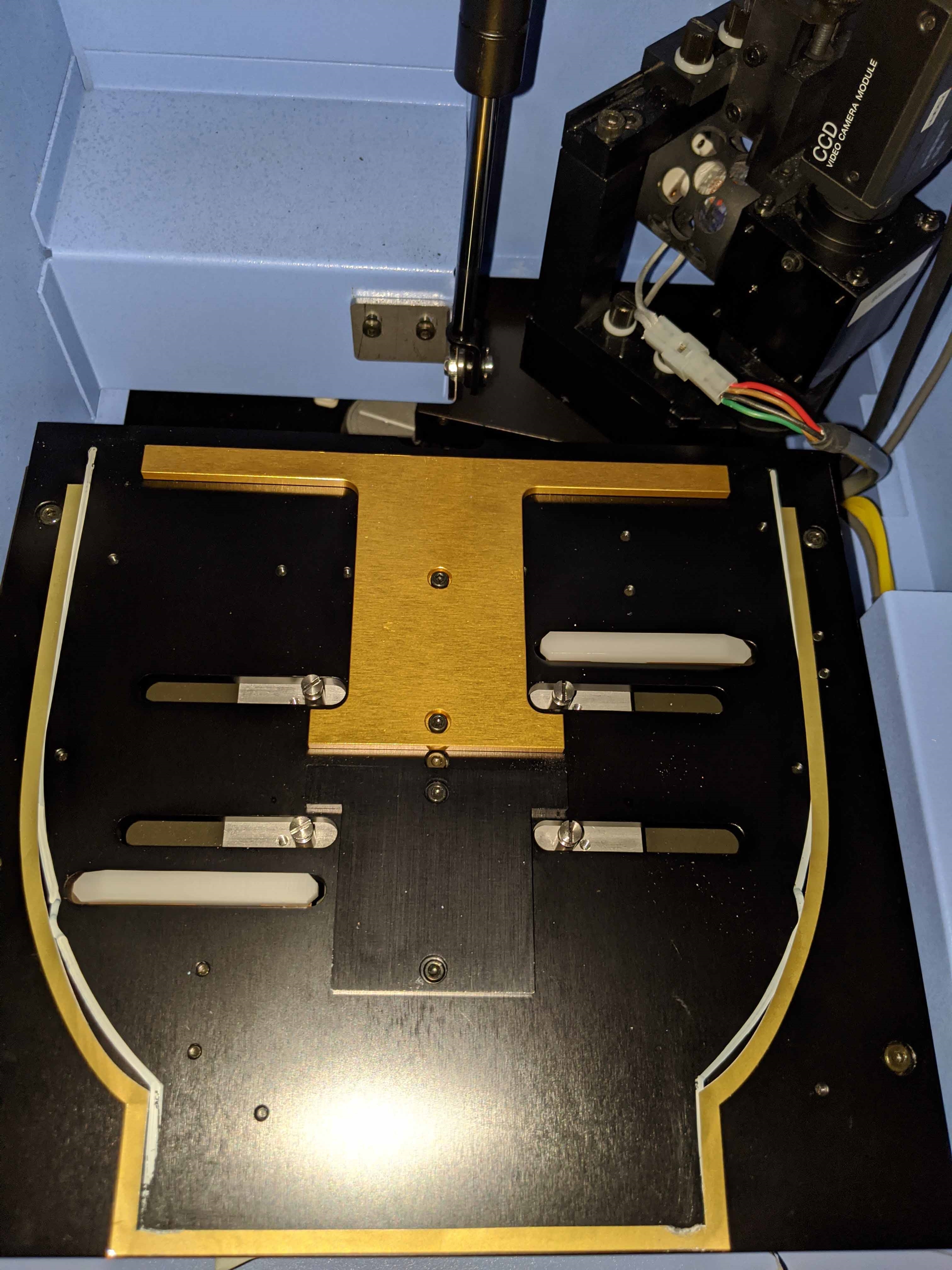

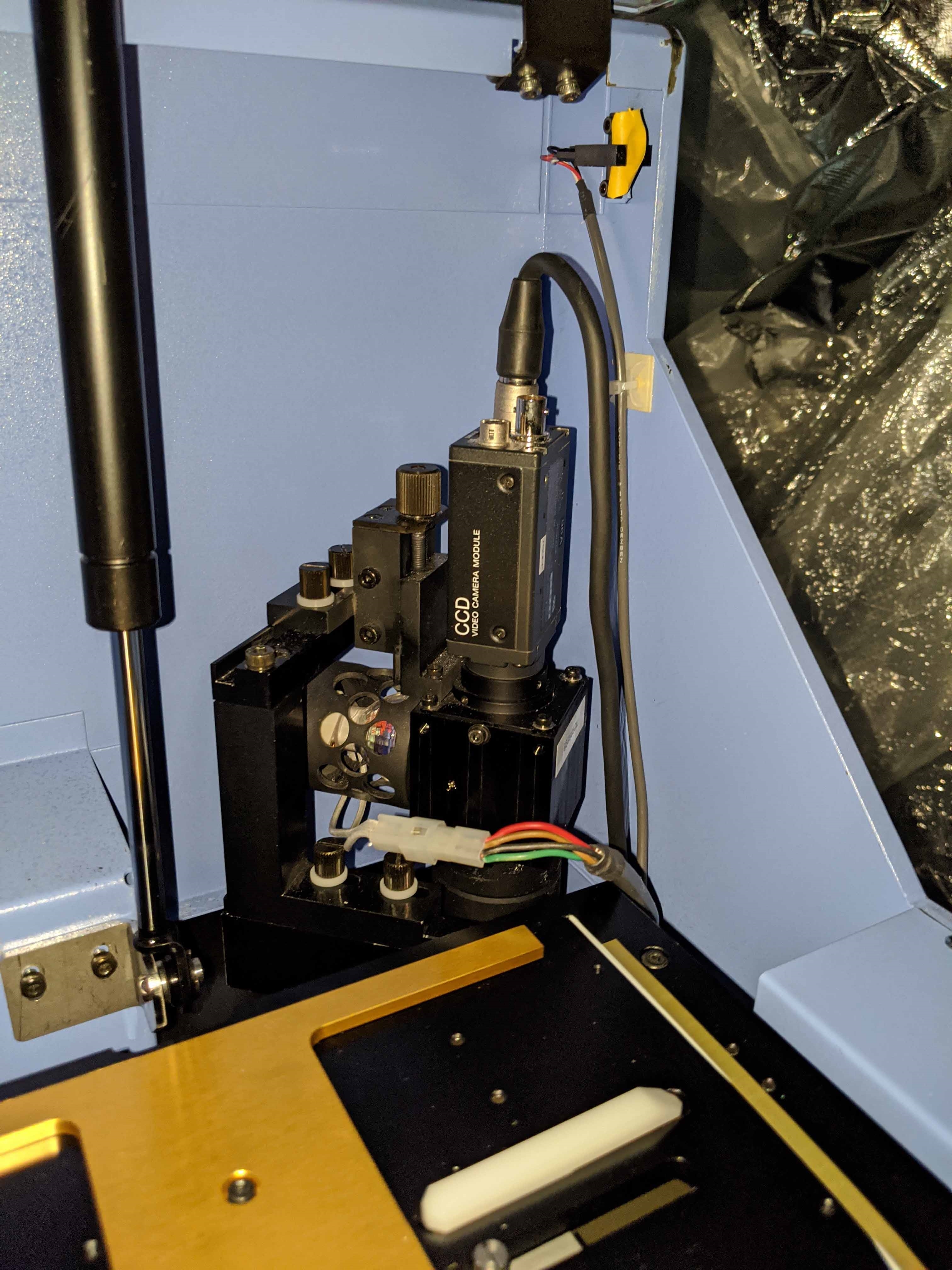

ACCRETECH / TSK UF 200 Prober is a semiconductor inspection and testing machine designed to help engineers assess the quality of integrated circuits (ICs) while they are still in the production process. It is a high-precision, automated equipment that uses a variety of advanced technologies to measure the electrical characteristics of small passes and devices. The system can be configured to test and monitor up to 200 wafers at a time, with a throughput rate of up to 20 wafers a minute. This is allows for easy and efficient testing, without operators needing to manually move or change wafers. TSK UF 200 Prober has a variety of different features, designed to make testing fast and accurate. The unit uses two independent probing stations, each with a 500mm x 500mm probe window and a scan area of up to 4.5mm. Each station has its own high resolution camera, allowing for precise positioning of probes and inspection during testing. It also includes an auto-contact algorithm, with precise settings for probe contact and wafer surface contact, to ensure precise and accurate testing. Additionally, the machine uses a variety of different settings for different devices, including Ohmic, MOSFET, and Electron Mobility Measurement (EMMT). This ensures precise and accurate testing each time. ACCRETECH UF200 Prober also has a variety of additional features designed to optimize testing and inspection. It has a number of optional accessories, including rotation and vibration mechanisms, which help to ensure stable, consistent testing by preventing wafer motion. The tool also comes with a contour pre-alignment feature, which helps to maintain a precise position of the wafers, ensuring accurate testing. Additionally, it includes a wafer-defect mapping asset, which can be used to help engineers identify and pinpoint any possible problems with the ICs being inspected. ACCRETECH / TSK UF200 Prober also has a number of software features to help engineers with the testing process. The model comes with a variety of statistical analysis tools and reporting options, to help give engineers an in-depth look into the testing process. The equipment also includes a hardware debugging system, allowing engineers to quickly and accurately troubleshoot any potential issues with their ICs. Finally, it supports remote access, allowing engineers to monitor and control the unit from any location. Overall, UF 200 Prober is a versatile, efficient, and precise machine for testing and inspecting ICs in the production process. With its variety of features, it is an excellent choice for engineering teams looking for high-precision testing and inspection. Its high-throughput rate and precision make it a great choice for any environment, from research and development to high-volume production.

There are no reviews yet