Used ACCRETECH / TSK UF 200AL #9283865 for sale

URL successfully copied!

Tap to zoom

ID: 9283865

Vintage: 2000

Prober

Platform: 93K

Floppy Disk Drive (FDD)

Hard Disk Drive (HDD)

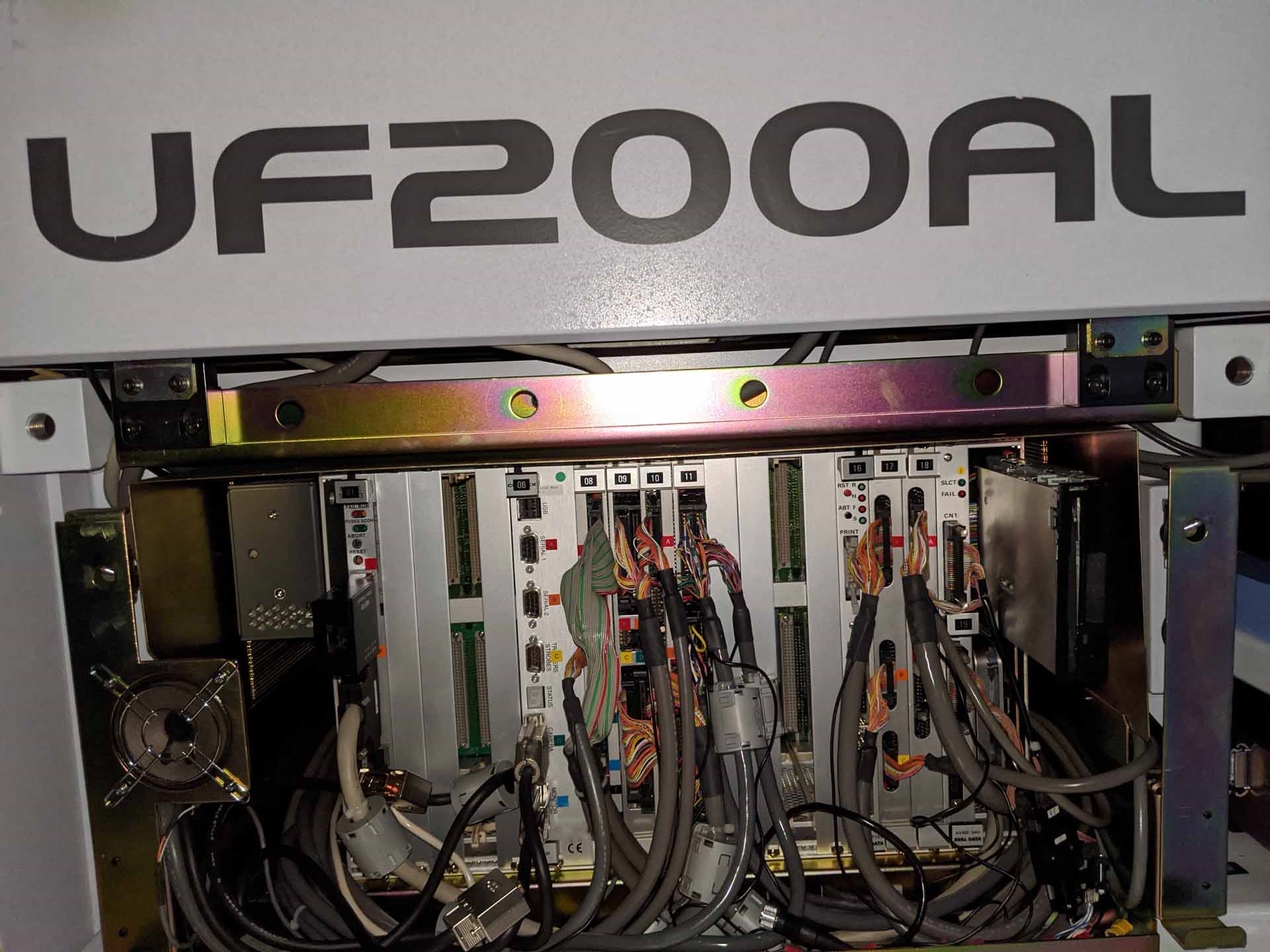

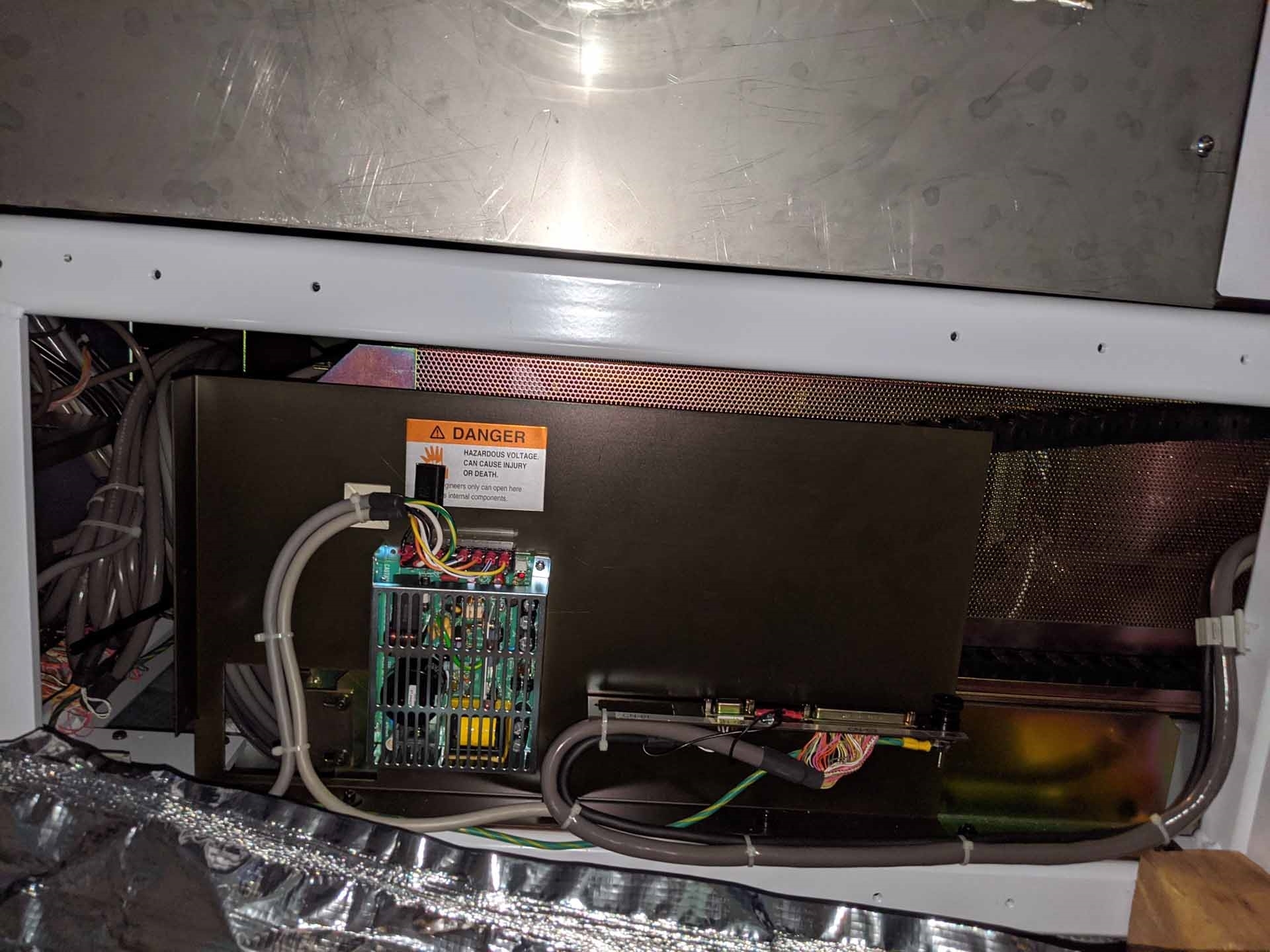

Control rack:

Z-Axis driver

XY Servo drivers

Power control board

Video interface board

Power supply: (2) 24 V, 12 V, -12 V, 5 V, 48 V

VME Rack:

Slot / Board

Slot 1 / Master CPU

Slot 4 / VGA Card

Slot 5 / VGA Card

Slot 6 / COGNEX Board

Slot 8 / PIO Board

Slot 10 / GPIB Board

Slot 11 / 5-Channel PGEN board

Slot 14 / DISP Sensor

Slot 16 / Slave CPU

Slot 17 / Loader I/O

Slot 18 / Loader PGEN

Main body read side:

Driver board

F-Server driver

Theta server driver

(2) Fans

Moire divider board

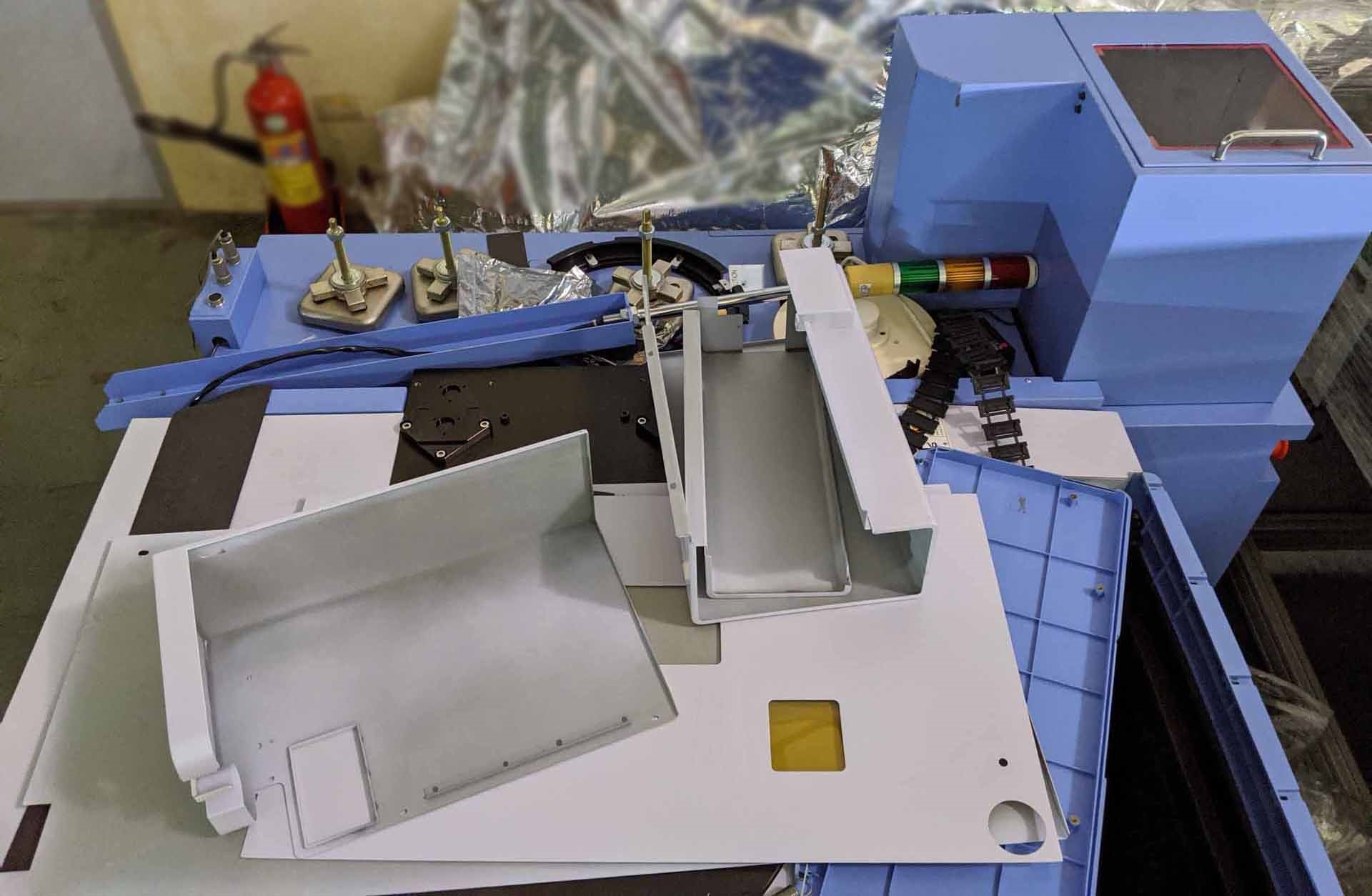

Loader side:

Loader driver board

OCR Camera

Loader sensor board

Loader axis board

Cassette cover

Elevator motor driver

Sub-chuck rotation motor driver

Turntable motor driver

(2) Transfer motor driver arms

Pre-alignment sensor

(2) Arms

Sub-chuck

Inspection tray

Temperature controller

Elevator / Clamper

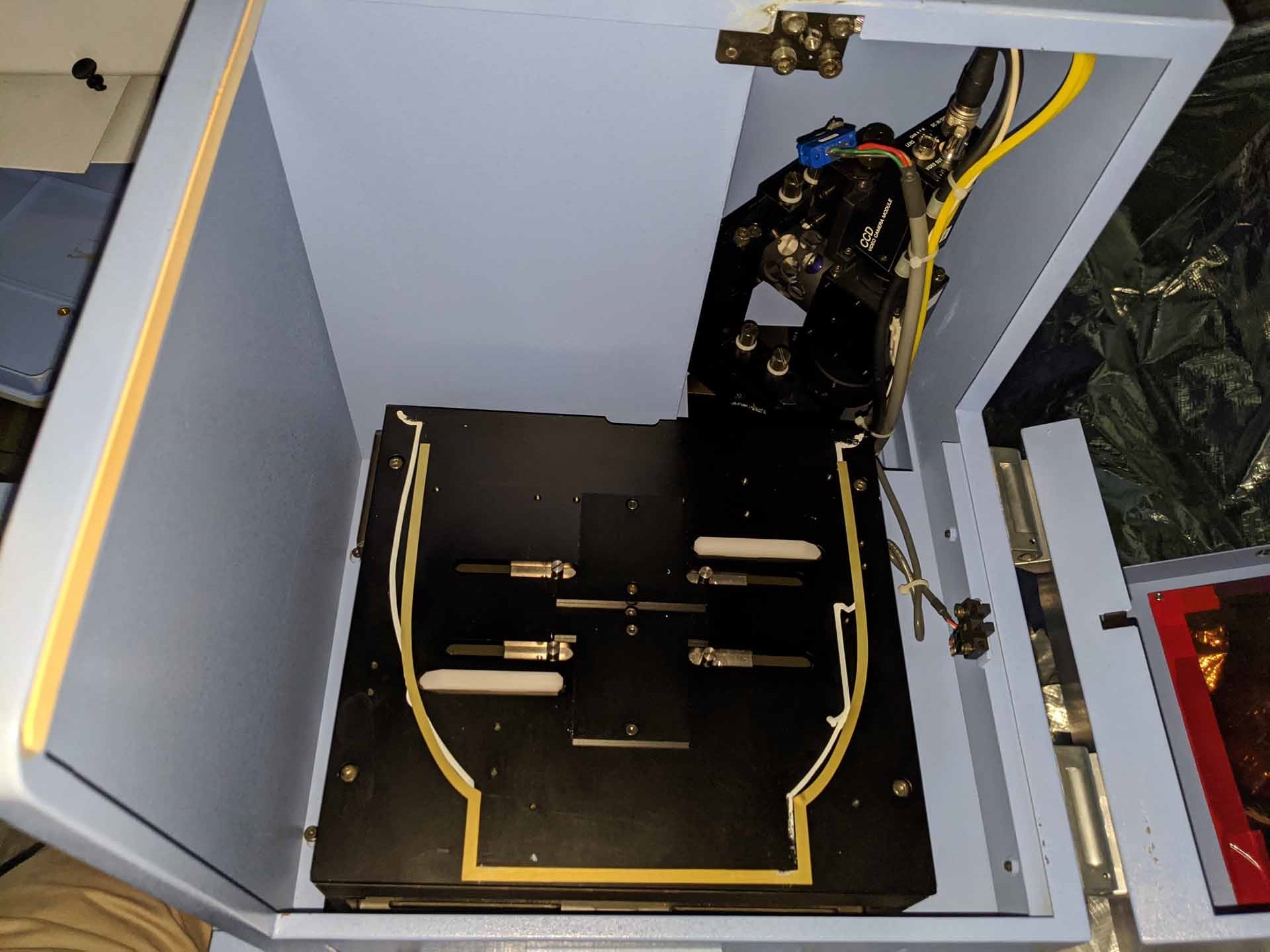

Chuck top

Z-Unit

(2) XY Axis screw and motors

F-Axis screw

E1, E2 Camera module

Touch panel

Keyboard and joystick

Keyboard control board

Alarm lamp pole

Miscellaneous:

Free stopper (Cassette cover)

Valve

2000 vintage.

ACCRETECH / TSK UF 200AL tool is a probe solution for on-site debug and fault isolation. This device offers a unique combination of a high sensitivity probe head and low mass, low noise force-measuring capabilities, allowing for fast and accurate measurements of accuracy, on-site adjustments and fault detection. TSK UF200AL features a low noise, differential force/displacement sensor that can measure forces with a resolution as low as 10 nanonewtons. The design of the probe head also helps to minimize dynamic and static calibration errors for more stable measurements. ACCRETECH UF 200 AL also offers an optional ultra-fine adjustment flex arm, which allows for measurements to be taken from the same location without subjecting the probe head to high forces. ACCRETECH UF 200AL includes a digital data acquisition equipment that integrates with a PC or PLC. This allows for data from the probe head to be acquired, stored, processed and displayed on the user's PC or PLC. The internal memory also allows for up to 20,000 measurements which can be routinely compared to pre-set thresholds. ACCRETECH / TSK UF 200 AL can also be used to create a point-by-point correlation between probe force and displacement. This correlation system helps users measure with great precision and accuracy in the compact form factor. The unit also allows the users to measure assemblies and adjust tolerances. UF 200 AL features an intuitive and easy-to-use user interface, allowing operators to quickly and easily calibrate the probe head. The interface also comes with software options and settings, which allow users to acquire live data and locate any defects with great accuracy. UF 200AL is designed to be robust and reliable, providing consistent performance while measuring and diagnosing faults. The machine also comes with a wide range of accessories to ensure a wide selection of applications and material configurations. Overall, TSK UF 200AL is an ideal solution for on-site solution for debug and fault isolation, with its high sensitivity probe head and reliable, accurate and repeatable measurements. With its wide range of accessories and intuitive user interface, UF200AL also offers great flexibility for users to customize the setup and make quick adjustments to optimize the tool for the application, enabling faster and more accurate diagnostics and modifications. As such, ACCRETECH UF200AL is ideal for on-site adjustment and fault detection in a variety of situations and settings.

There are no reviews yet