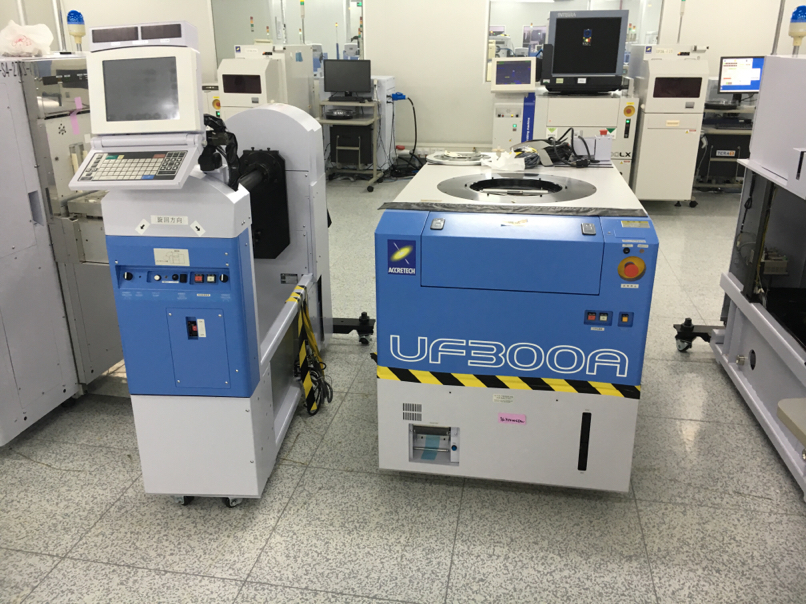

Used ACCRETECH / TSK UF 300 #9128306 for sale

URL successfully copied!

Tap to zoom

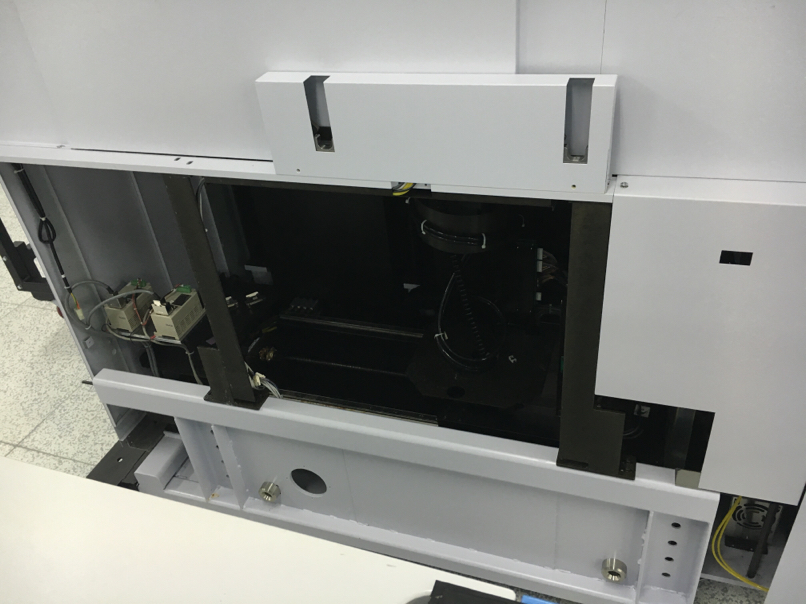

ACCRETECH / TSK UF 300 is a prober equipment from the Osaka, Japan based TSK Corporation. The system is used for a variety of device analysis and electrical testing tasks. TSK UF 300 unit features a 4-axis prober arm, with six probes and a vision machine for localization. It is designed to be a flexible, reliable and cost effective tool for a variety of probing tasks. ACCRETECH UF300 asset is capable of testing wide range of device sizes and types. It utilizes a 150 mm x 150 mm x 3 mm test area with a maximum stroke area of 105 mm x 75 mm. The 4-axis prober arm affords motion in the X, Y, Z, and ⅔ axes, with a maximum speed of 5 m/s and acceleration of 5G. The model also supports a variety of probes, including flat tipped probes, spring loaded probes, vertical (tungsten) probes, electrical probes, and alignment pins. The equipment is automated, allowing for easy testing of devices, both manual and automatic. ACCRETECH / TSK UF300 also features a vision system for localization, allowing for automatic and efficient scope mapping and accurate device positioning. The unit consists of a digital image camera, CCD camera, micro-mirror array, and light sources. It can process images with a resolution of 400nm x 400 nm and performs image acquisition, device alignment, and probe positioning automatically. The machine is capable of integrating a wide variety of test tools, such as ultra-thin porometers, environmentally sealed resistors and capacitors, wavelength meters, and colorimeters. The tool has software options available, such as E-Z Test, which can be used to run automated test scripts and perform statistical analysis, and TestLogger, a data acquisition and analysis program. Overall, ACCRETECH UF 300 is an automated prober asset designed for industrial testing of a wide variety of device types. It features automated vision model for device localization, and a 4-axis prober arm with 6 probes and a max speed of 5 m/s. The equipment can integrate a variety of tools, both manual and automatic, through the use of software options. The system is cost effective and reliable, making it suitable for use in a variety of industries and applications.

There are no reviews yet