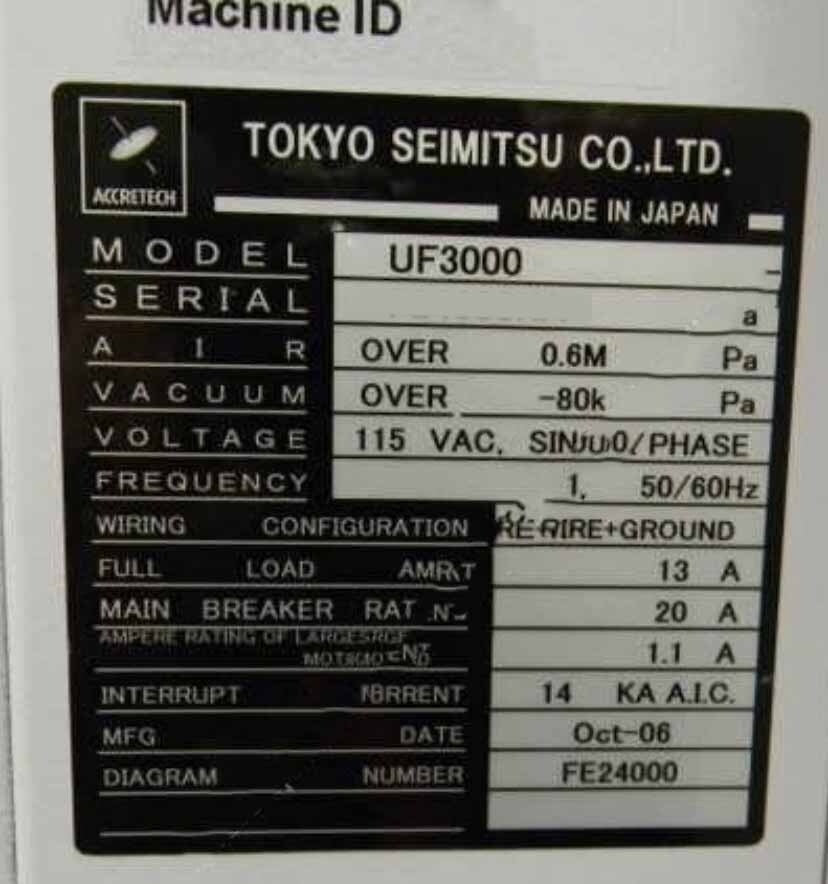

Used ACCRETECH / TSK UF 3000 #293621713 for sale

URL successfully copied!

Tap to zoom

ID: 293621713

Wafer Size: 12"

Vintage: 2006

Wafer prober, 12"

Process: V5400 Hot air

Load port

ATT A300T Air cooled chuck

X,Y Overall accuracy: ±2.0 µm (Temperature stability: ±1°C)

X,Y Stage accuracy: ±1.0 µm

Z Axis stroke (Applicable stroke): 37 mm

Z Axis control accuracy: ±2 µm

Stage durability: 200 kgf

Does not include Hard Disk Drive (HDD)

Power supply: 120 AC, Single phase

2006 vintage.

ACCRETECH / TSK UF 3000 is a prober used for electrical testing of precision electronic components. The device is used in quality assurance and production monitoring processes. It features a 3D pattern recognition equipment that can detect component positions and alignment, and can detect micro-shortages, misalignments of components, and other anomalies in fine electro-mechanical devices. The prober is capable of operating at high speed, with throughputs of up to 600 wafers per hour. It is equipped with automated wafer handling and wafer loading systems that allow for rapid product cycle times and increased throughput. The device consists of a stationary base and a x/y axis system that allows for a wide range of motion. The prober can accurately measure components within a 40mm range and is adjustable for range and precision of measurement. Additionally, it is capable of manual or automated inspection and measurement of parts with a resolution of up to 14 nanometer (nm). The prober is equipped with an AccraGaugeTM optical measurement unit that can detect the presence or absence of micro-shortages, and with AccraVisionTM software, which allows for improved efficiency and accuracy in testing. The prober is also equipped with a vision machine that includes a high-speed camera, surface lighting, and an extensive set of parameter settings. The AccraVision software allows operators to specify certain feature sizes, detection locations, and tolerances so that the device can accurately detect any anomalies in the components being tested. The AccraGauge tool uses a 3D vector map to accurately measure the 3D distances between features on the components, and to create a map of the component surface. The prober is designed for a high level of precision components and is available in three form factors: 1-up low-profile, 2-up mid-height, or 3-up high-profile. It also provides a built-in wafer lift process that allows operators to access corners of the wafer and problematic areas in wafers to access delicate or obscure components. The output of this prober is both in real-time online, and is also available offline for further analysis and review. The prober is designed for the testing and electrically measuring of precision electronic components, and is an ideal tool for quality assurance and production monitoring of components and assemblies. In addition to its features and detection capability, it provides users with a robust and reliable platform for testing components, with a high throughput rate and built-in automated wafer handling and wafer loading.

There are no reviews yet