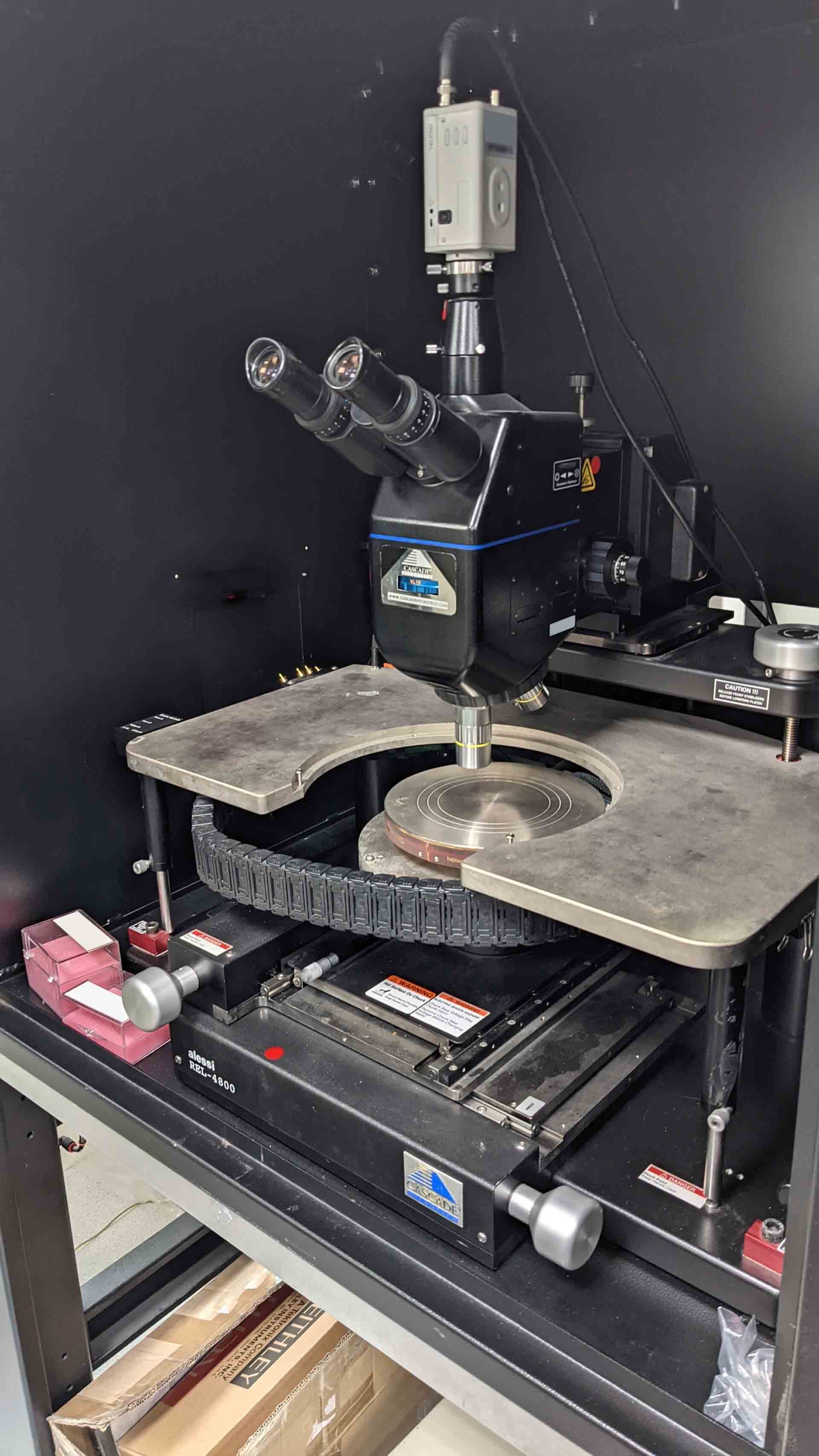

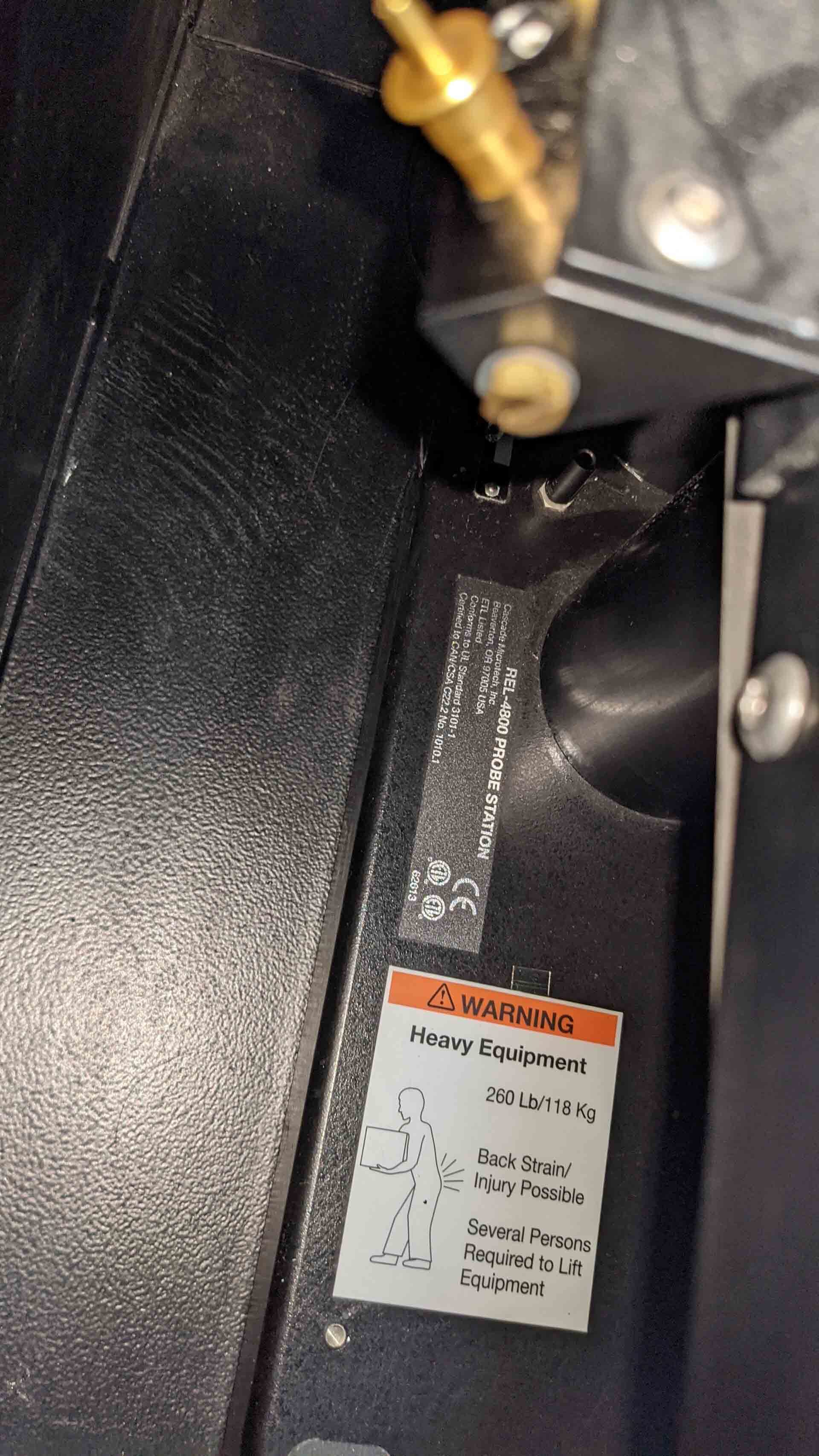

Used CASCADE MICROTECH / ALESSI REL 4800 #9299808 for sale

URL successfully copied!

Tap to zoom

CASCADE MICROTECH / ALESSI REL 4800 is a prober designed for contact probing of a variety of materials, such as metals and ceramics, for measurements in strict accordance with pre-defined standards. It is a highly flexible solution for meeting the demands of testing centre applications with its broad range of probe configurations and range of test field sizes. The prober features a force module designed to control the contact pressure between the sensor and the material tested. The force module is programmable to achieve precise levels of friction, contact force, contact depth, and contact speed. The optimal tension regulation ensures uniform force distribution over the entire test surface so as to achieve the most accurate test results with minimal risk of probe damage. The sensor is designed with a robust aluminum enclosure which contains the laser-positioned sensors, the electronics sheathing, the motors, and the drive train. The enclosed design minimizes the risk of dust and dirt contamination of sensitive components inside the prober and protects the sensor from the surrounding environment. The motion equipment is designed to provide a maximum motion resolution of up to 0.1 nanometers. The motion-control system is based on a 32-bit microprocessor ideally suited to multi-axis applications with high-resolution motion and damping capability. The precision DC servo motor drives, coupled with a high power amplifier, ensure the highest accuracy, repeatability, and low power consumption. The prober offers a number of testing modes, including semi-automated and fully automated testing on a variety of material types. The automated mode allows for tightly-controlled testing cycles which are precise and repeatable. The motion unit of the prober can also be enabled for de-bounce testing, testing in an open envelope or closed rectangle conditions, and contact-closure testing. The prober is also designed with a variety of data acquisition and process monitoring features. The sensor is connected to a secondary board which can be programmed with multiple measurement applications and feedback loops. This board interfaces with a number of inputs and outputs from the prober, enabling the collection of detailed statistics on the operating parameters and tests conducted. In addition to these technical features, the prober is designed according to best safety practices. The robust construction and safety-rated components ensure that the machine is able to withstand daily wear and tear and potential collisions with other objects in the test environment. The enclosure is designed to protect the sensor from dust and dirt, and the ESD protection ensures that the prober is not subjected to dangerous electrical discharges while operating.

There are no reviews yet