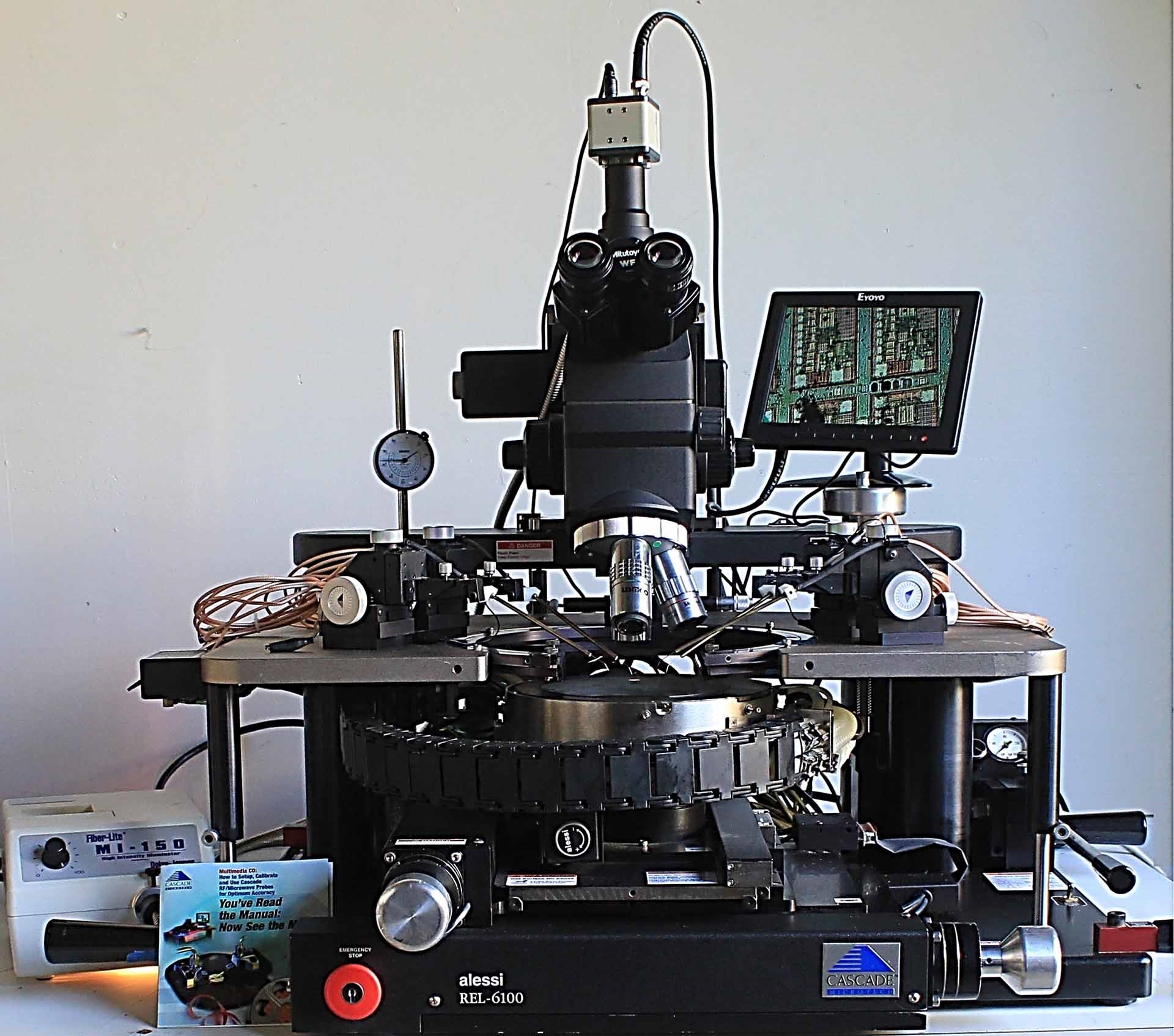

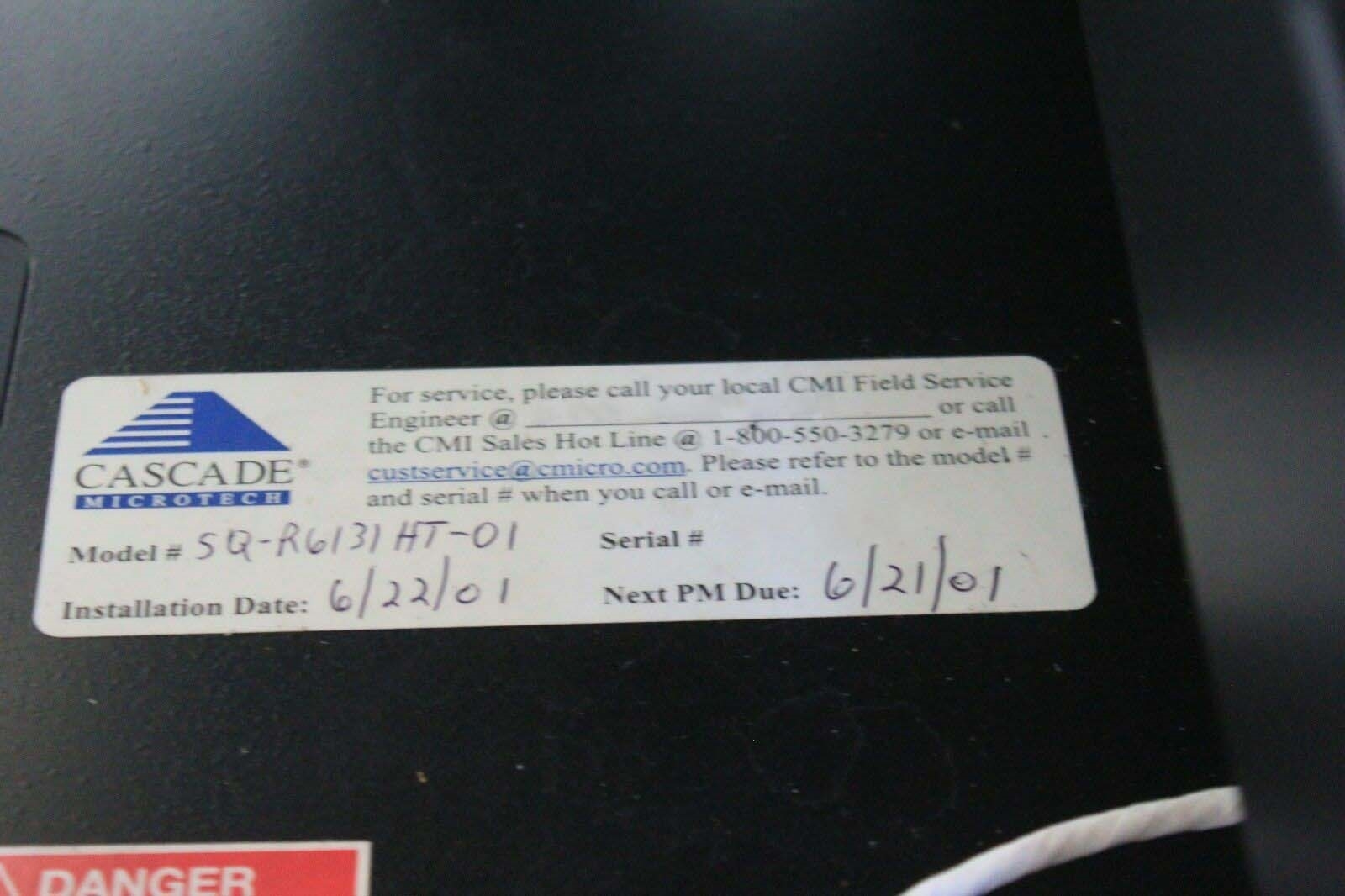

Used CASCADE MICROTECH / ALESSI REL 6100 #9209134 for sale

URL successfully copied!

Tap to zoom

ID: 9209134

Wafer Size: 8"

Prober, 8"

For DC, RF probing

Thermal chuck

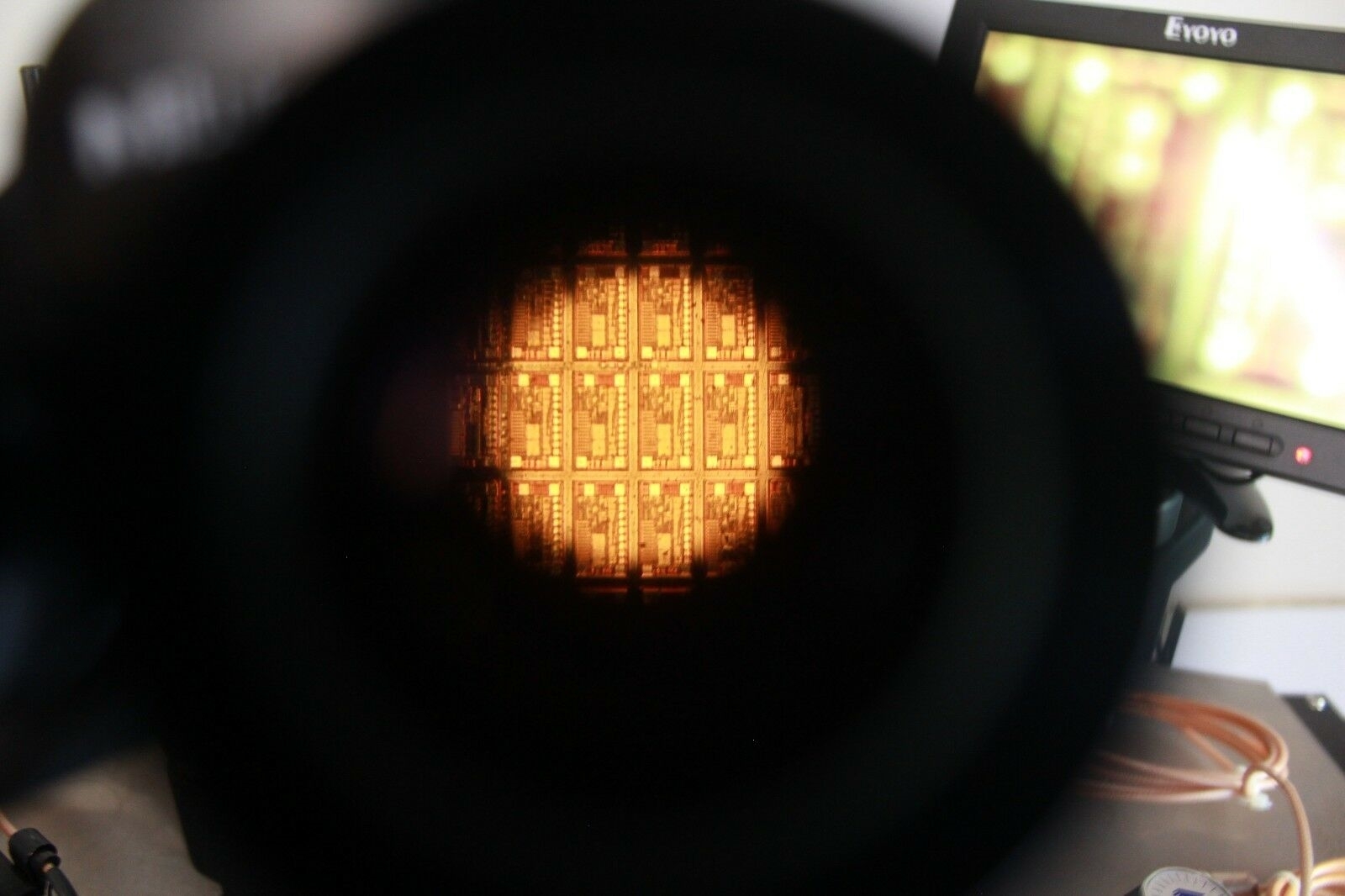

MITUTOYO Scope

Chuck:

Guarded triaxial hot chuck with cable sand tube, 8"

Microscope:

MITUTOYO Microscope

10x Eyepiece

Magnification: 400x

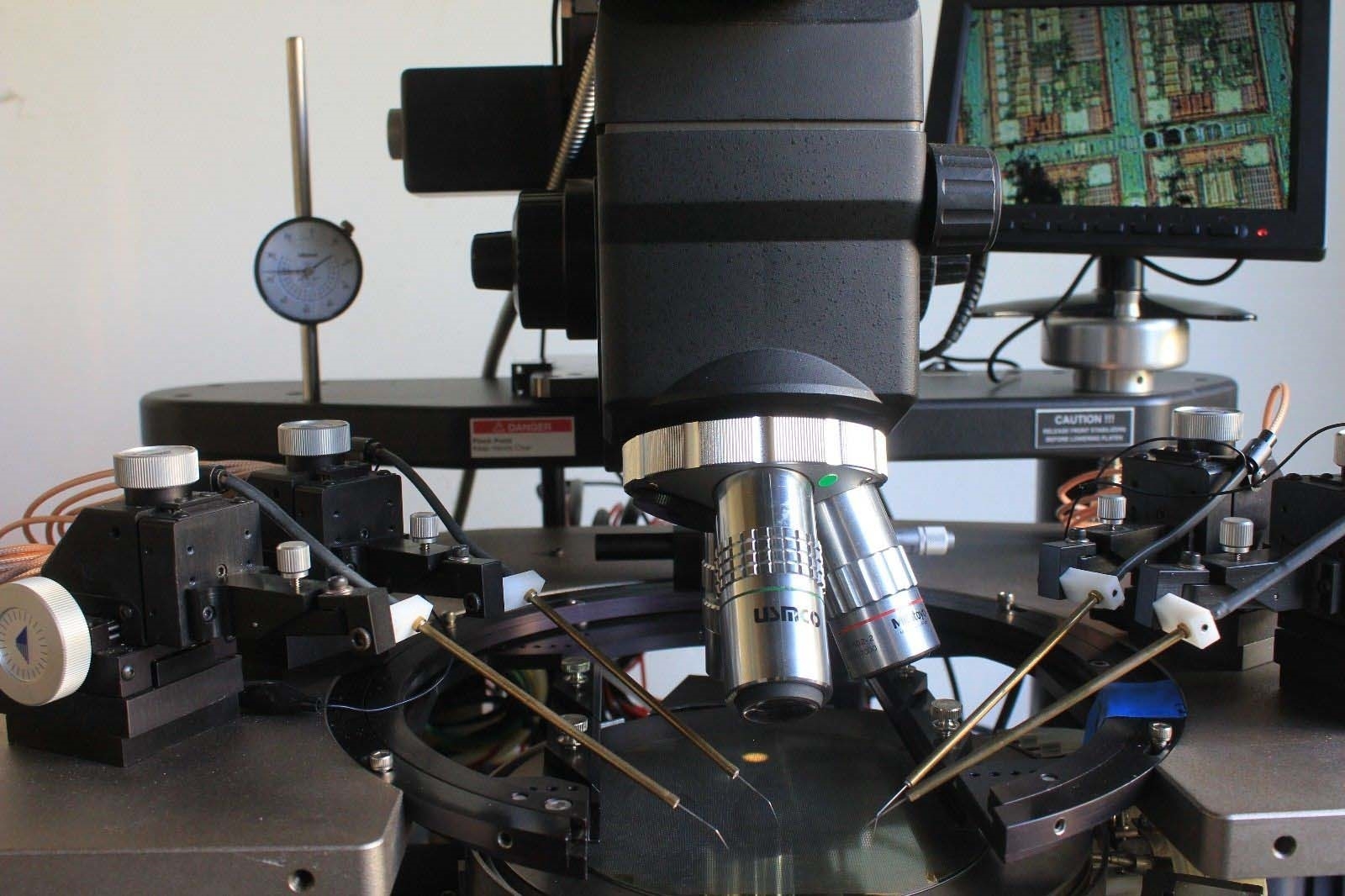

(3) Objectives: 2x, 5x, 20x

Color CCD camera with monitor

Power supply

Cables included

Does not include:

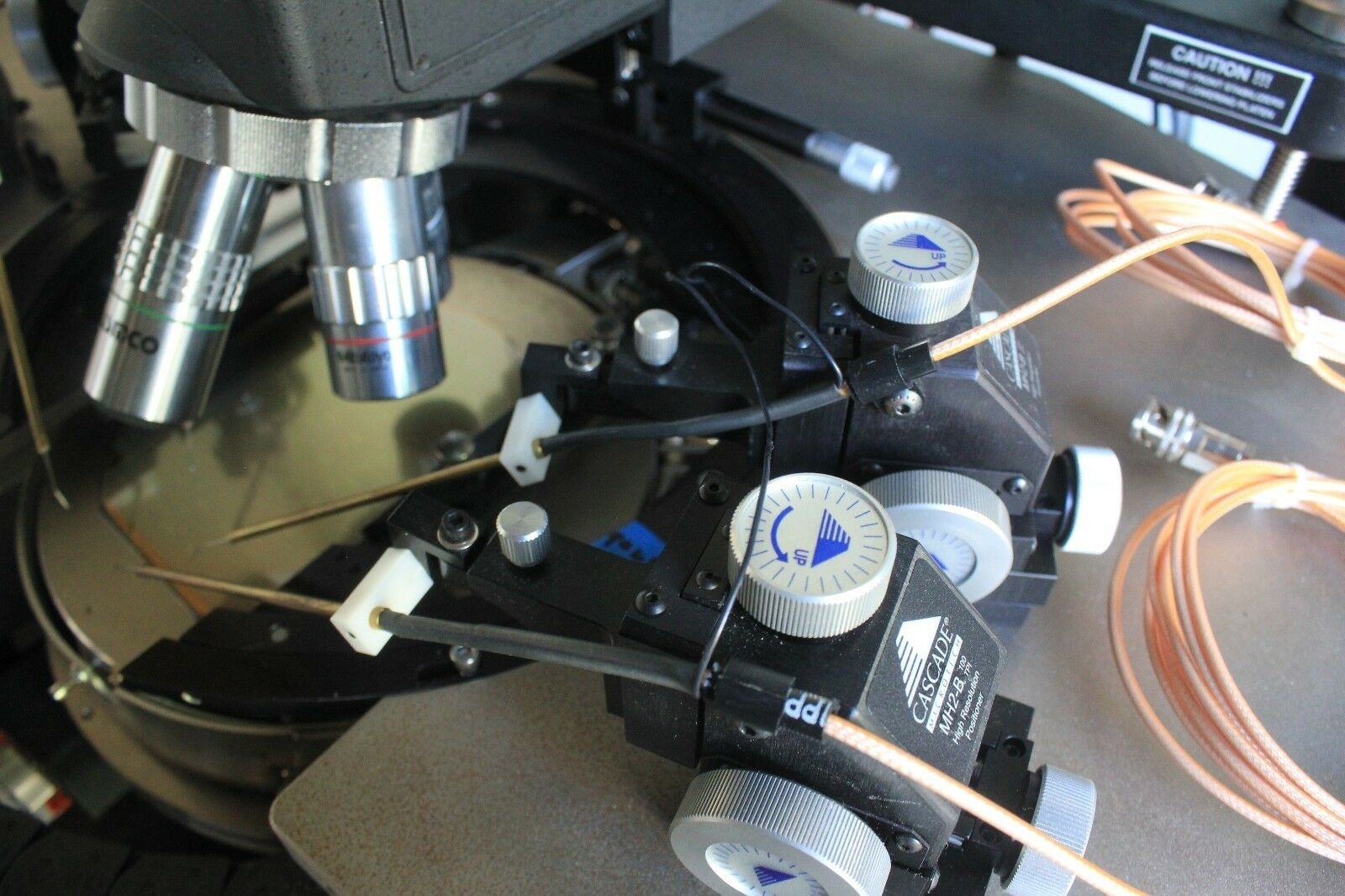

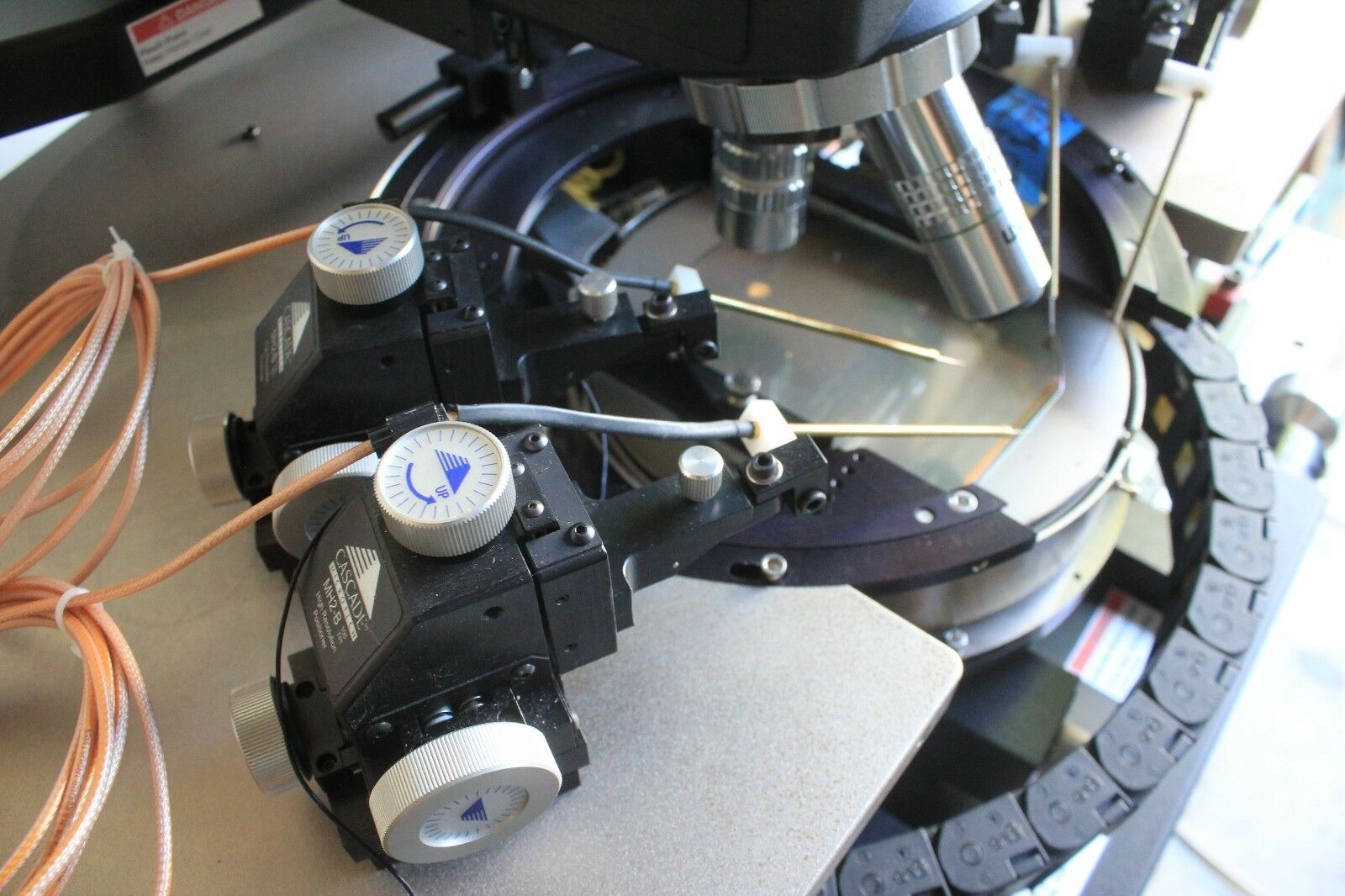

(4) CASCADE DC positioners

MH, DC and RF Probes

Thermal controller

EX56

Joystick

Stability bridge

X, Y, Theta control of 8"(200 mm) chuck and platen Z

Platen configured for cascade RF, DC positioners

No laser.

CASCADE MICROTECH / ALESSI REL 6100 is a prober specifically designed for probing applications in wafer sorting and fault isolation. ALESSI REL-6100 prober is configured using automated programming of the stages, sample load, static and dynamic probing tips, and selection of optional components and extension structures. CASCADE MICROTECH REL 6100 has an innovative stage design for excellent stability, as well as the ability to quickly adjust to different test and contact environment setups. The prober has a static and dynamic probe carriage equipment, which enables the testing of several contact points simultaneously. The static probe is mounted on a carriage that allows for quick and precise positioning of the contact points within the sample area, while the dynamic contact probe carriage system allows for a more accurate, repeatable measurement of electrical properties. CASCADE MICROTECH REL-6100 features a high-precision XYZ stage unit that ensures a highly-accurate application of force, featuring a maximum travel of up to 50 microns. The stage machine can be programmed for precise movement, which is then incorporated into the stage movements for faster and more accurate probing. The motion tool of CASCADE MICROTECH / ALESSI REL 6100 is driven by a brushless DC servo motor, which ensures smooth and repeatable motion and low power consumption. The servo motor is also able to adjust its speed based on the severity of the probing action, and can be programmed to achieve a maximum of 10,000 cycles per minute. The constant velocity feature of the servo motor ensures that the speed of the motion is consistent throughout. Built-in automation systems can be used to adjust the sample-loading parameters, as well as the conditions and parameters used for probing. To ensure proper alignment and alignment accuracy, REL-6100 prober includes an optical alignment asset. The model includes an alignment scope that is built in to the design, so it can be adjusted according to the user's requirements. REL 6100 from ALESSI is an excellent prober for wafer sorting and fault isolation applications. Its high-precision XYZ stage equipment, brushless DC servo motor, and automated programming make it an ideal choice for precision probing and mapping of contact points. The integrated optical alignment system ensures accurate alignment and provides the highest level of contact-point accuracy. The prober is suited for a wide variety of applications, including digital, analog and high-frequency testing.

There are no reviews yet