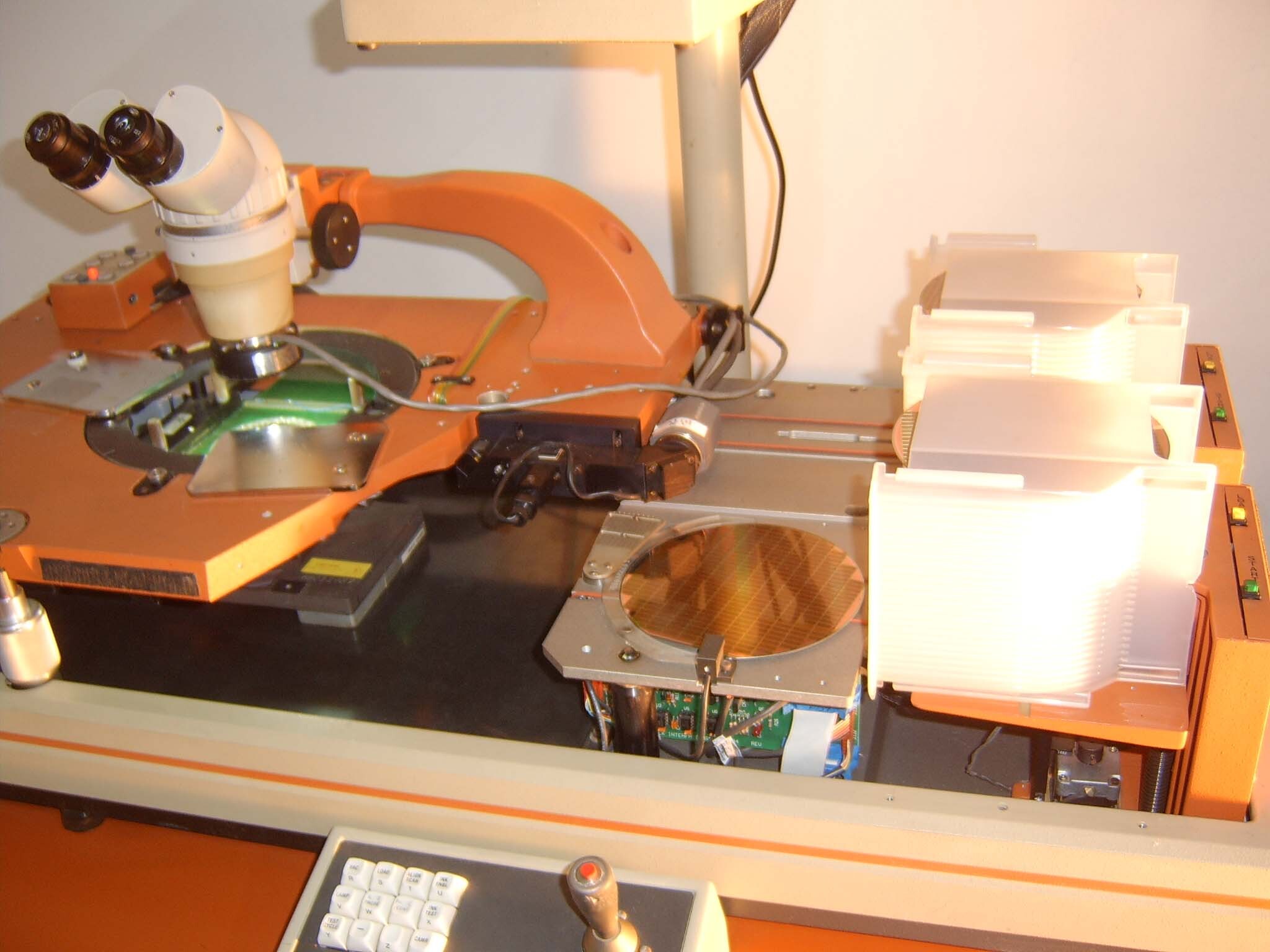

Used ELECTROGLAS / EG 2001X #125078 for sale

URL successfully copied!

Tap to zoom

ID: 125078

Wafer Size: 6"

Full auto probe station, 6"

Version : CD version

Vision module : COGNEX

Hard ware configuration

6" auto wafer prober

ring carrier

probe card holder

6" gold chucktop

Z-stage 0.25 mil

ZY stage with base unit controller

W/F profile unit

Auto ailgn unit w/ccd optic assy

9" B & W monitor

Operator console assy

6" wafer auto loader kit

Interface: TTL / RS232C / GPIB

OLYMPUS microscope

High table & low table.

ELECTROGLAS / EG 2001X is a highly advanced prober designed to provide precision analysis of semiconductor devices. It is a fully automated and configurable analyzer that can be used to perform both manual and fully automated probing operations. It is equipped with an 8-channel equipment which allows for simultaneous probing of up to 8 devices or wafers. The system includes a mechanical/thermal measurement unit integrated into a large environmentally controlled enclosure. This enclosure features auto-adjustable sample stages, contact force sensors, environmental sensors, and integrated contactor/motor controls. The mechanical/thermal measurement machine of EG 2001 X allows for precise data acquisition and analysis of probe-to-target contact force, contact resistance, leakage voltage, and short/opens checks. The probes used in the tool can provide a range of contact forces for different types of tests. Additionally, the asset allows for contact-dependent measurement of thermal parameters. The software suite supplied with ELECTROGLAS EG2001X provides complete control over the prober and the probing operations. It includes a Probing Connectivity Manager, a Thermal Manager, and an SPC Analyzer that can be used to monitor and analyze test results. Additionally, the model has several data logging and statistical analysis capabilities, along with an integrated database for storing test records. EG2001X equipment is extremely reliable and accurate, and it allows for real-time feedback during probing operations. This makes it ideal for semiconductor device production and testing environments, as it allows for the high levels of precision and repeatability that are required in such systems.

There are no reviews yet