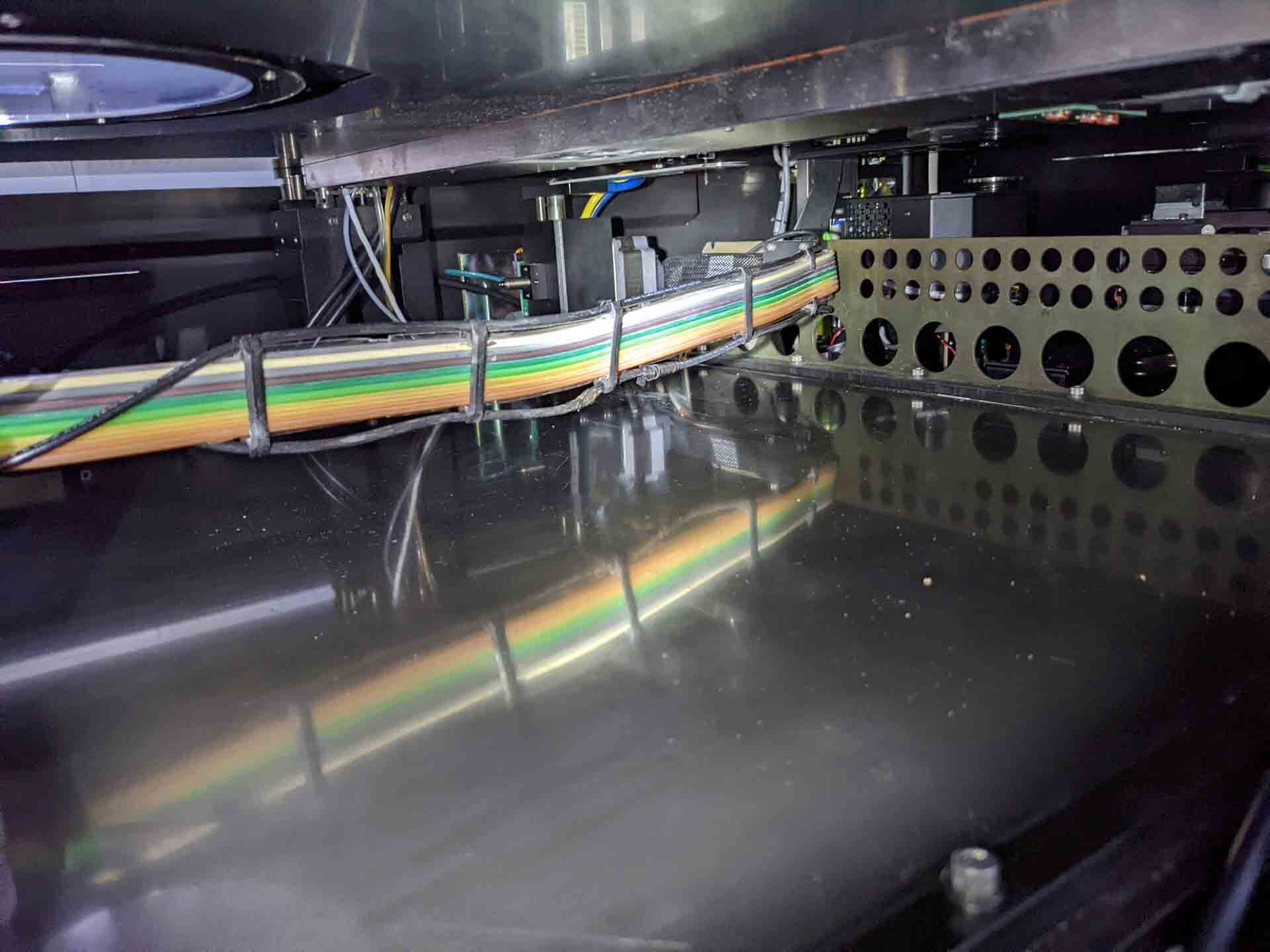

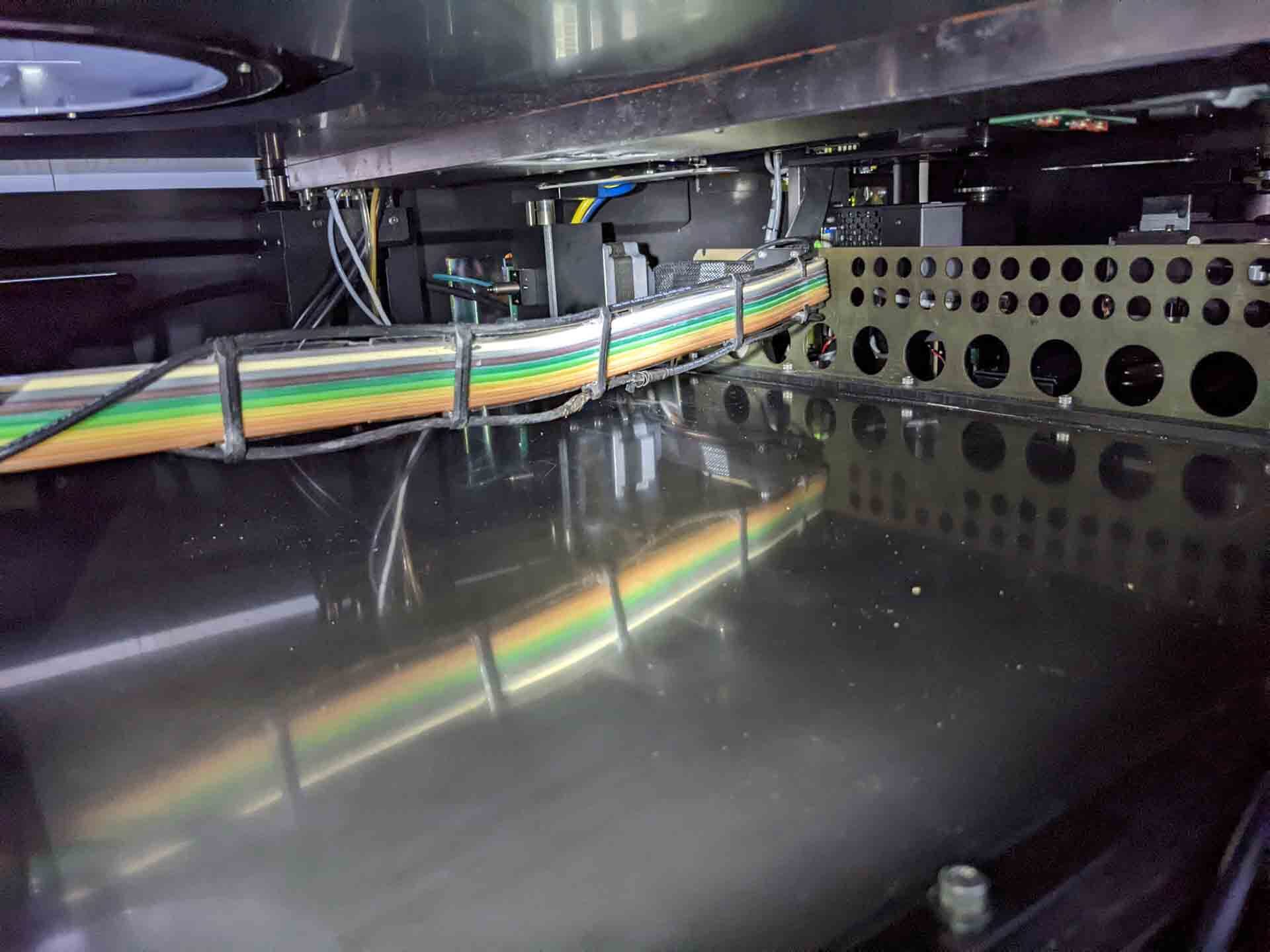

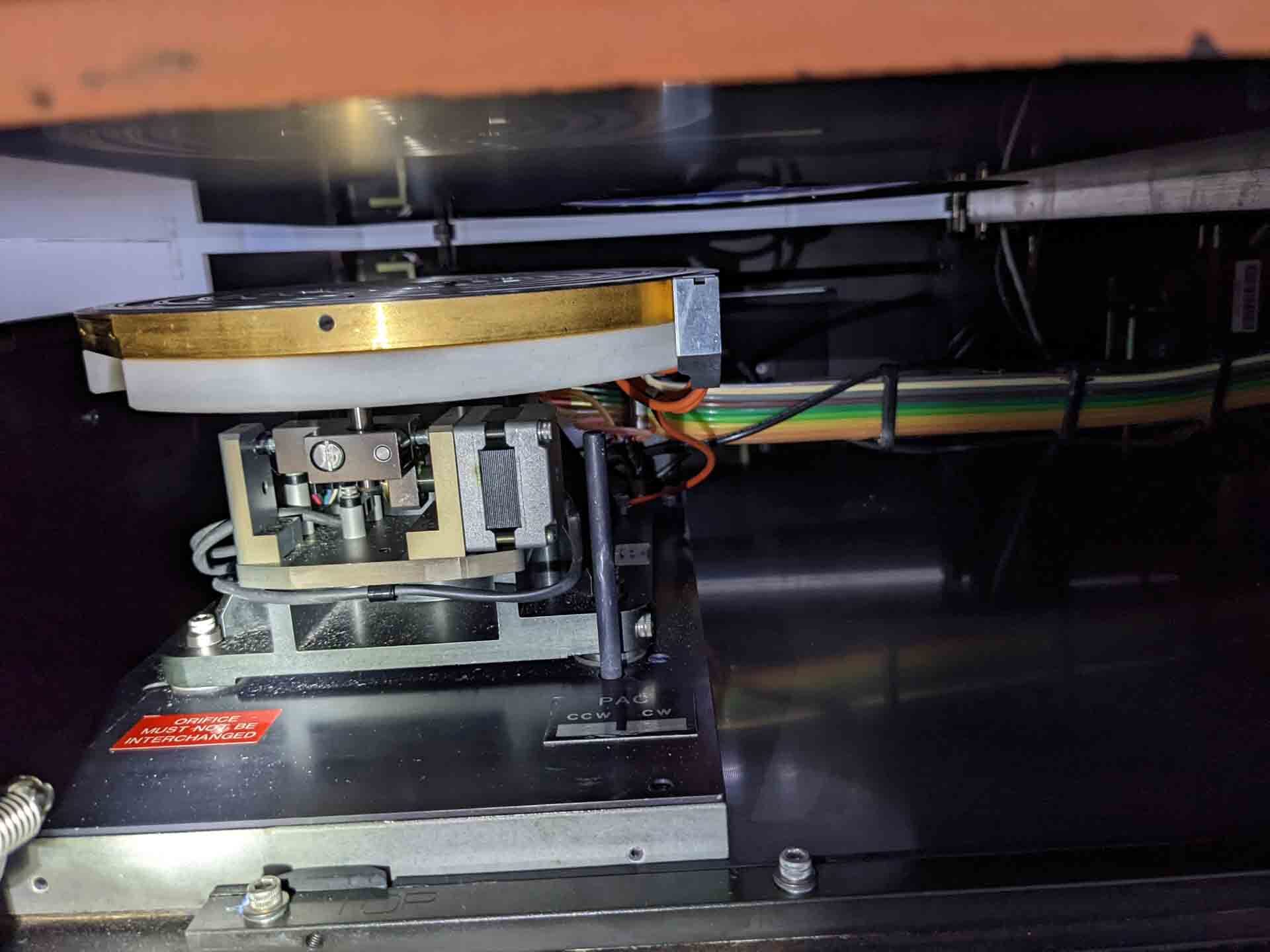

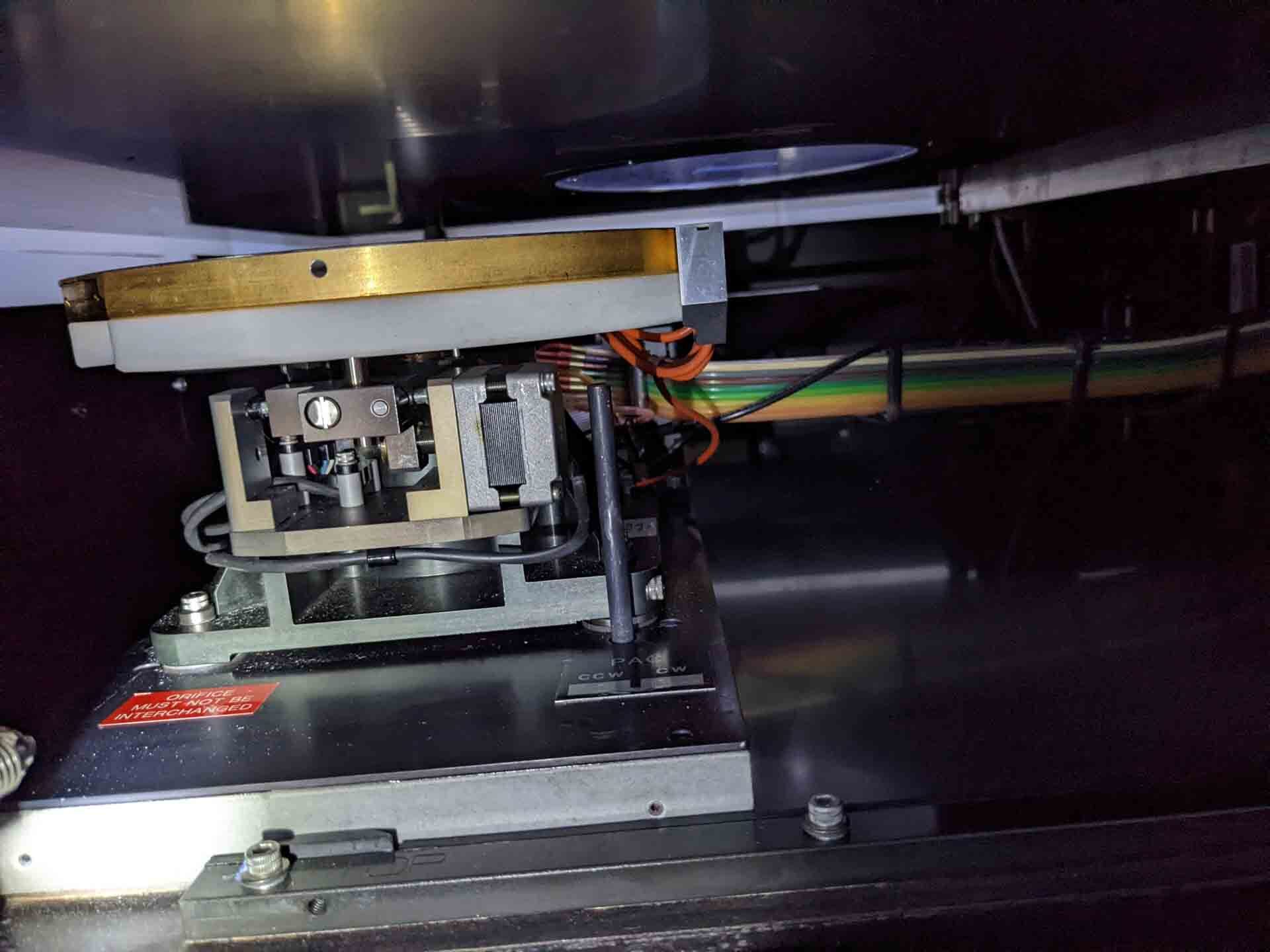

Used ELECTROGLAS / EG 4090u #293589344 for sale

URL successfully copied!

Tap to zoom

ID: 293589344

Vintage: 2002

Prober

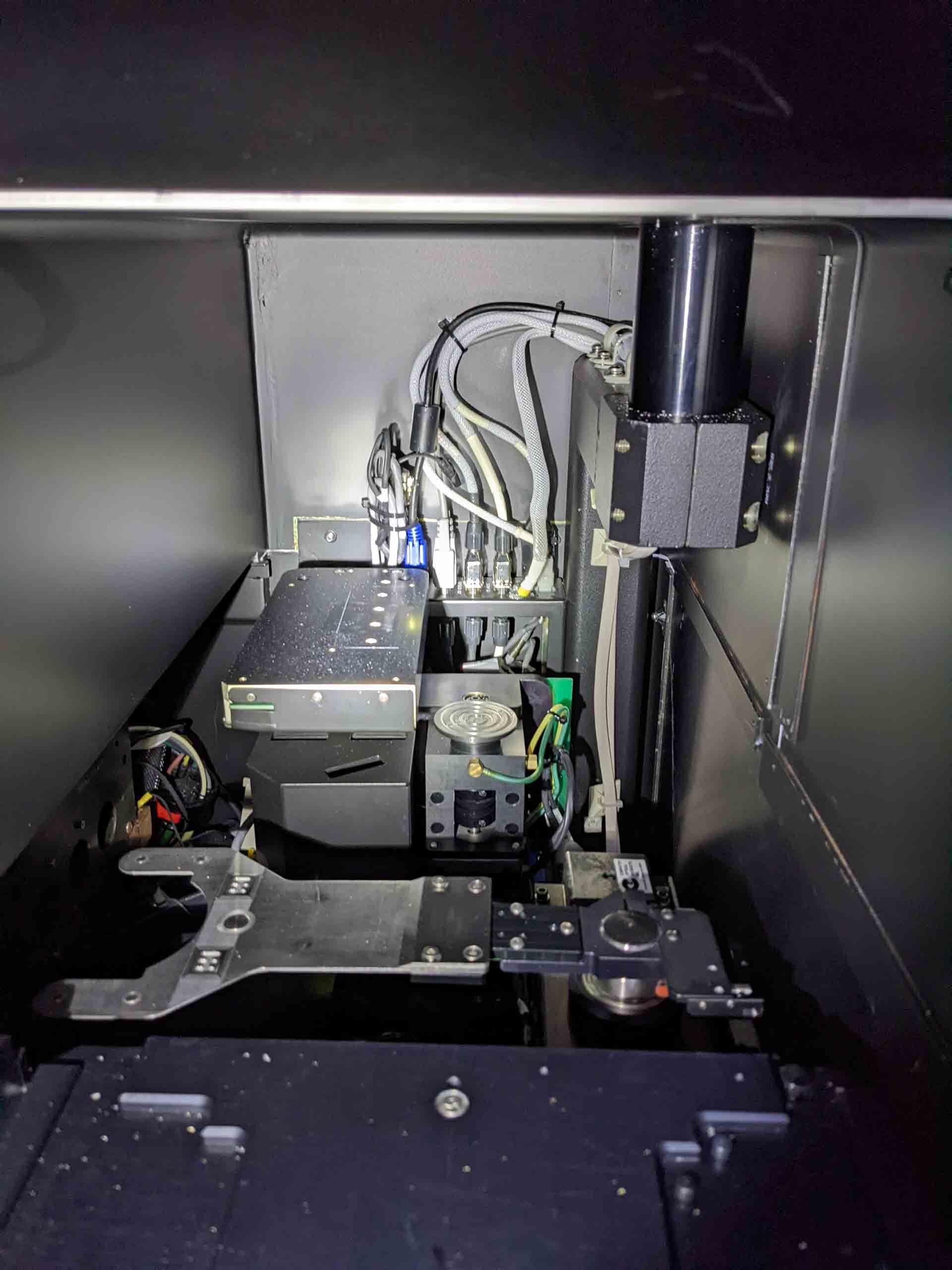

Commander version: DOS EGC 7.3.8

DCM Version: DCM 2

VM Alignment system

Z-Stage: 0.125

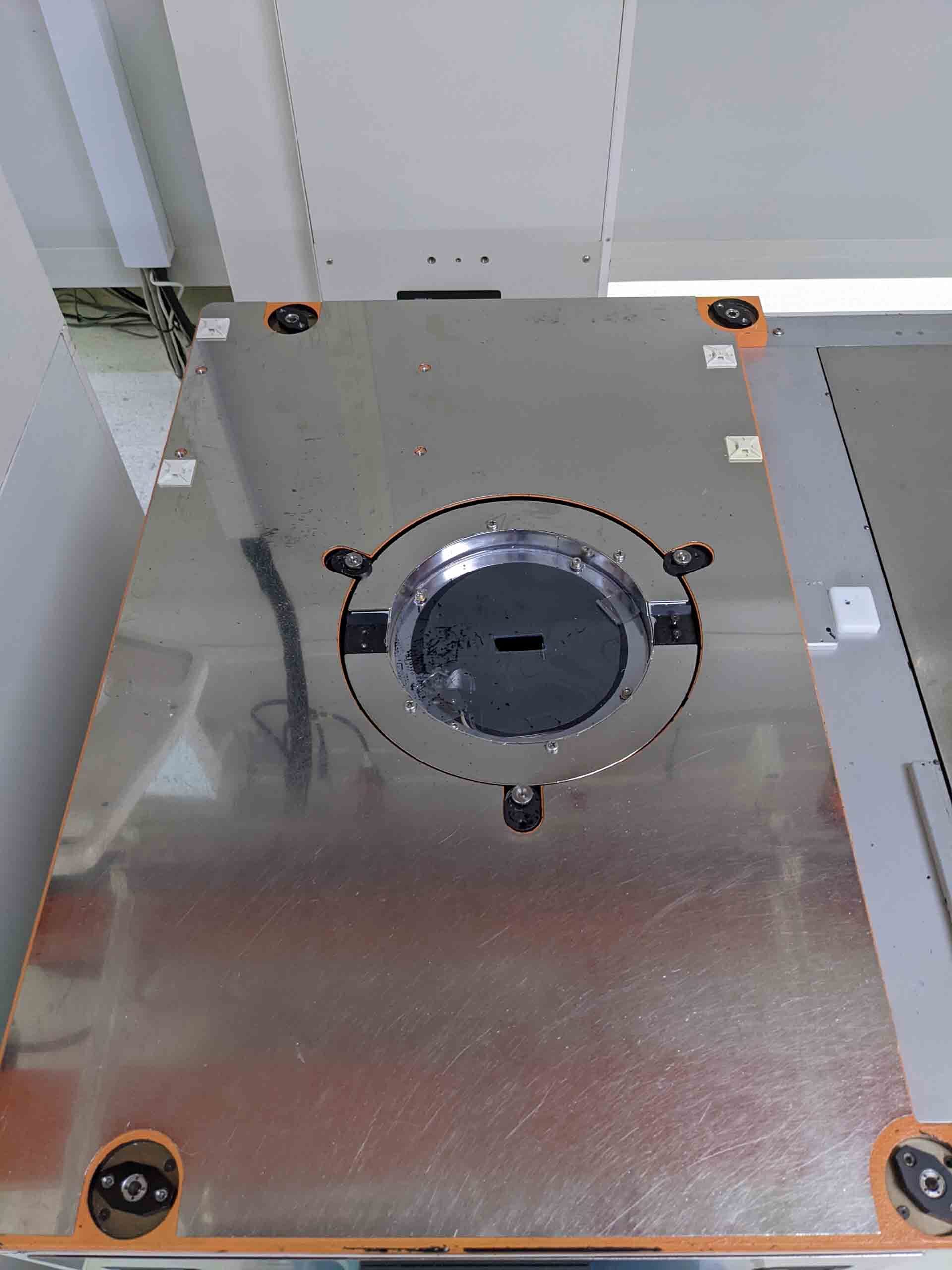

Chuck material: Gold

Chuck type: Hot

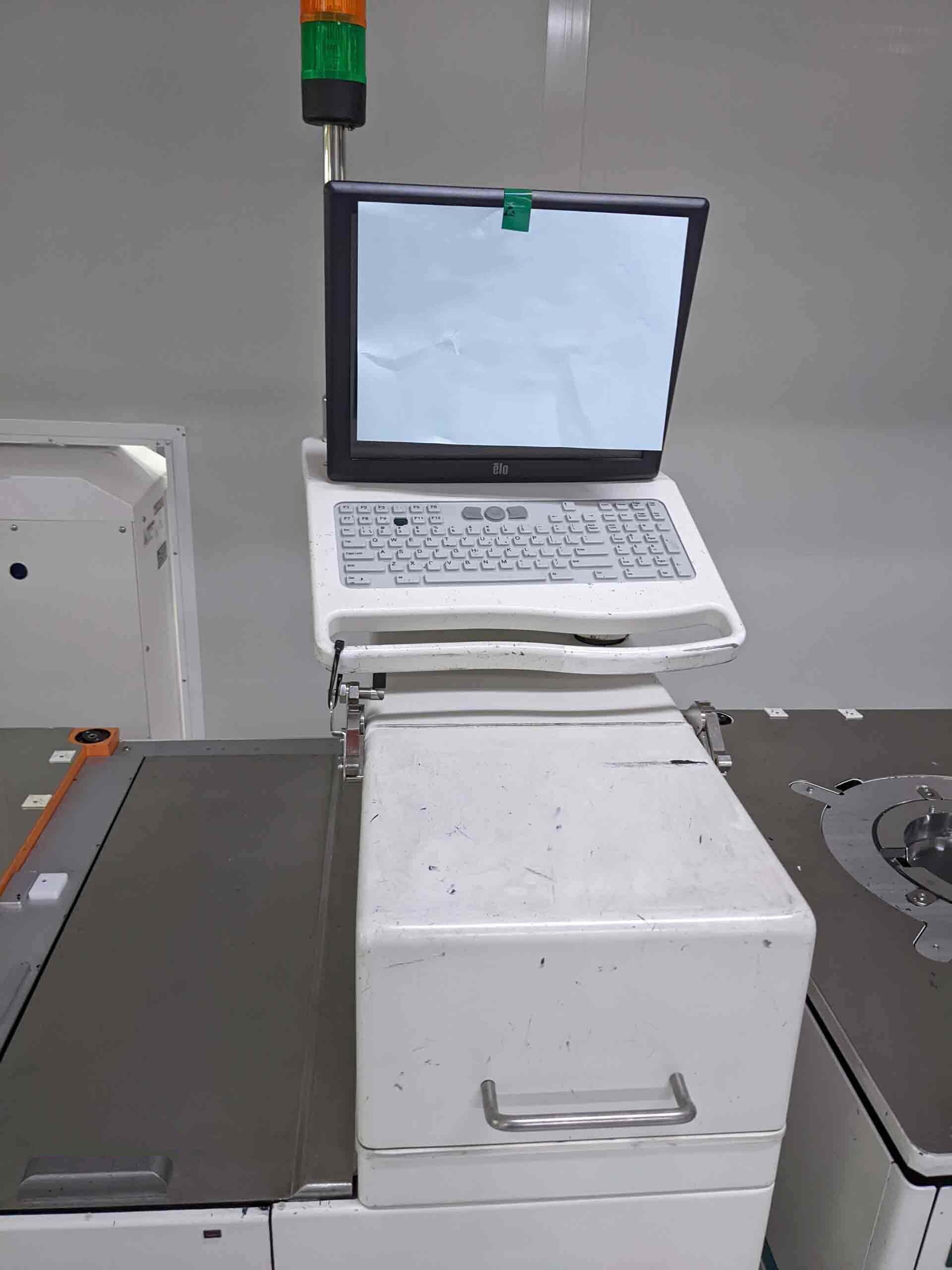

LCD Monitor

Material handler module

Display control module

Prober control module

Vision module

OCR Camera

Bridge camera: COHU

2002 vintage.

ELECTROGLAS / EG 4090u is an automated wafer prober designed for automated testing of semiconductor wafers, bare die, and singulated chips. The prober features a robotic arm capable of travel on three axes—x, y, and z—and a four-point probing equipment. The robust design of the probe can accommodate semiconductor wafers up to 200mm in diameter. The high-resolution, programmable two-axis sample staging system allows for precise placement of the wafers, while the four-point probing unit ensures accurate and repeatable contact. The machine has four different probing technologies: high-resolution x-y (XY), Force Control, Contact Automation, and Interconnects. The XY probes provide reliable placement accuracy of less than 1 micron and a three-dimensional integrated movement tool that securely supports wafer probing. The force control probes provide very fast clamping speed with uncompromised performance, resulting in improved throughput. The contact automation probes are designed for high-reliability contact performance, even in automated reflow environments. The interconnect probes make it possible to evaluate wire bonds and other interconnect features. The asset also features an advanced scanning algorithm to ensure accurate and repeatable probing. The proprietary software can run independent scans for each of the four probing technologies. The model's advanced feedback control algorithms provide reliable performance and improved testing throughput. EG 4090u can also be configured with an optional camera equipment for real-time monitoring of wafer probe sites. Other features of the system include a wafer handling unit, a fault detection machine, and a wafer alignment tool. The wafer handling asset includes a special cassette model which stores and transports wafers in multiple formats. The fault detection equipment enables users to detect faulty sites prior to probing. The wafer alignment system allows for the precise positioning of the wafers, ensuring accurate and repeatable probing results. The unit's intuitive graphical user interface provides operators with easy and direct access to the machine's various functions.

There are no reviews yet