Used MICROMANIPULATOR 1800 #9171121 for sale

URL successfully copied!

Tap to zoom

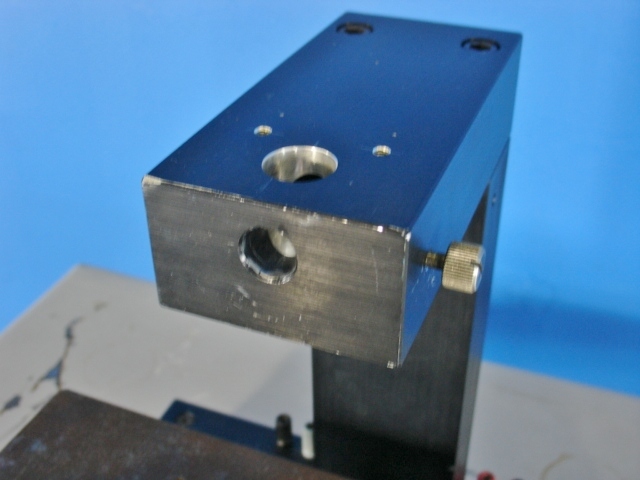

MICROMANIPULATOR 1800 is a highly advanced and sophisticated Semiconductor Prober that is used for precise probing of advanced semiconductor wafers during production testing. It is used by production staff for testing and inspecting individual chips that are being produced. This prober is designed to be used in a cleanroom or lab environment and is equipped with a robust environmental control equipment to ensure that any contaminants or impurities present do not adversely affect the performance of the device being tested. 1800 consists of a vacuum chuck system which holds the wafer securely in place during testing. The vacuum chuck unit ensures that the wafer is level and secure during the probe operation. To ensure precise probe results, the chuck machine contains an array of two-dimensional pins and a fine pitch rotating mechanism. The rotation mechanism ensures that the tip of the prober is always at the correct angle when probing the device. Additionally, the probe itself is equipped with a motorized pin plunger that can be adjusted to suit the device's specific requirements. MICROMANIPULATOR 1800 also features a laser beam alignment tool that can be used to align the probe tip precisely on the area needing probing. This laser beam alignment asset ensures that incorrect readings are not taken due to misaligned probe tips. Additionally, 1800 has a built-in vision model that is capable of performing real-time inspections of the device under test. The vision equipment can take multiple images of different positions of the device and analyse them to draw conclusions about the device. In terms of safety, MICROMANIPULATOR 1800 is designed with a number of safety measures in place, such as a protective transit shield and anti-static bars. The transit shield protects operators from hazardous conditions that could be created through the testing of the device and the anti-static bars prevent damage to the device under test caused by static electricity. 1800 has been proven to be a reliable and robust tool in the production testing environment. Its capabilities of precise probing and real-time visual inspections of devices have ensured its continued usage in production testing today.

There are no reviews yet