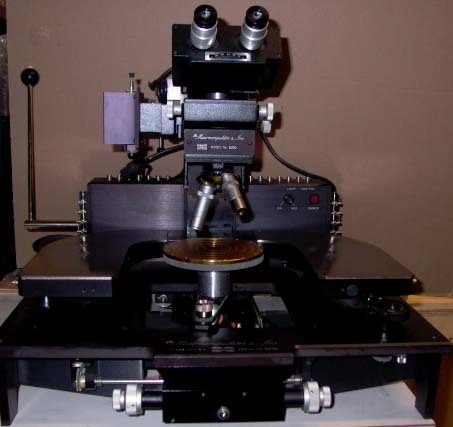

Used MICROMANIPULATOR 6200 #85275 for sale

URL successfully copied!

Tap to zoom

ID: 85275

Wafer probe station, 6"

Includes B&L Micro Zoom optics with (2) objectives, 6" chuck, 6x6" travel, manual movement

Accepts 10 or more magnetic or vacuum based manipulators

1 in. (25.4 mm) thick honeycomb construction for maximum stability

Fine Lift Control

True planar vertical motion, convenient knob control

Resolution: 0.3 micron per degree revolution

Range: 0.5 in. (12.7 mm)

Fast Lift Control

Raises platen and microscope with adjustable microscope lift delay

Range: 1.35 in. (34.3 mm)

Three locking up positions

Resolution: 18:1 reduction (handle:platen)

XY STAGE

Stage Movement

Range of motion 6 in. x 6 in. (152 mm x 152 mm)

Movement and vacuum stage planarity permanently set

at factory

Theta rotation control full 360° with conveniently located

locking knob

Control knobs coaxial X-Y for single hand operation from

either side, located center front

Vacuum Stage

Standard 5 in. (127 mm) diameter with dual tweezer

slots

Gold plated brass for low contact resistance

Flatness t.0005 in. (t 12 microns)

Electrical isolation exceeds 5000 megohms at 500VDC

OPTIONAL SOCKET STAGE

Conversion time vacuum to socket and back to vacuum

stage less than 60 seconds

Accepts P.C. cards with ZIF sockets for probing packaged devices while operating

Locking handle for theta rotation control

MICROSCOPE AND POST

Vertical positioning +1.4 in. ( support)

Vertical motion 0 -1.35 in. (34.3 mm) by platen fast lift

handle or fine control knob with adjustable delay

X-Y translation: 1 in. x 1 in. (25.4 mm x 25.4 mm) with

convenient knob control

Factory planarized X-Y translation

Coarse/fine focus control

Microscope

B&L MicroZoom with 2:1 zoom in body

3 long working distance objectives (2.25X, 8X, 25X)

Quadruple nosepiece accepts optional 50X objective

Trinocular head with camera port, 10X eyepieces

Coaxial illuminator with system mounted transformer and

infinite rheostat control.

MICROMANIPULATOR 6200 Prober is a high-precision instrument designed to accurately manipulate and measure microscopic components. The unit is designed for probing, imaging, and manipulation of microelectronics and can be used in a variety of applications. The precision and accuracy of the prober is ensured by a combination of both the manual and automated features. The prober offers an industry leading range of precision probes which are highly accurate, low back-drift and feature a wide range of tip sizes and shapes. This versatility allows for reliable, accurate probing of component pads and terminals. The probes are also suitable for imaging and analysis, as they can provide real-time digital imaging and analysis of components under test. The probes also allow for automated testing of components, such as electrical circuit elements, leads and components, as well as programming and component characterization. The prober also features a range of advanced image capture and analysis capabilities. This includes advanced vision software which can be used to analyze components and to create 3D images. The software also supports automated component detection and recognition for component sorting and manipulation. It also features automated component probing and determination. These features allow for accurate and repeatable component measurements and automated testing of components. 6200 Prober is designed for maximum user comfort and is easy to use. It features an intuitive user interface and intuitive documentation. It also features both a remote and on-site support network for technical assistance. In addition, the prober come with a comprehensive library of software tools, including a scripting language, firmware updates and. Overall, MICROMANIPULATOR 6200 Prober is a powerful, reliable and accurate tool which is ideal for a range of applications and uses. It is a high-precision instrument designed to accurately manipulate and measure microscopic components. It offers an industry leading range of precision probes which are highly accurate and feature a wide range of tip sizes and shapes. The prober also supporting advanced image capture and analysis capabilities and is easy to use. It is an ideal choice for those who need reliable, accurate and automated testing of components.

There are no reviews yet