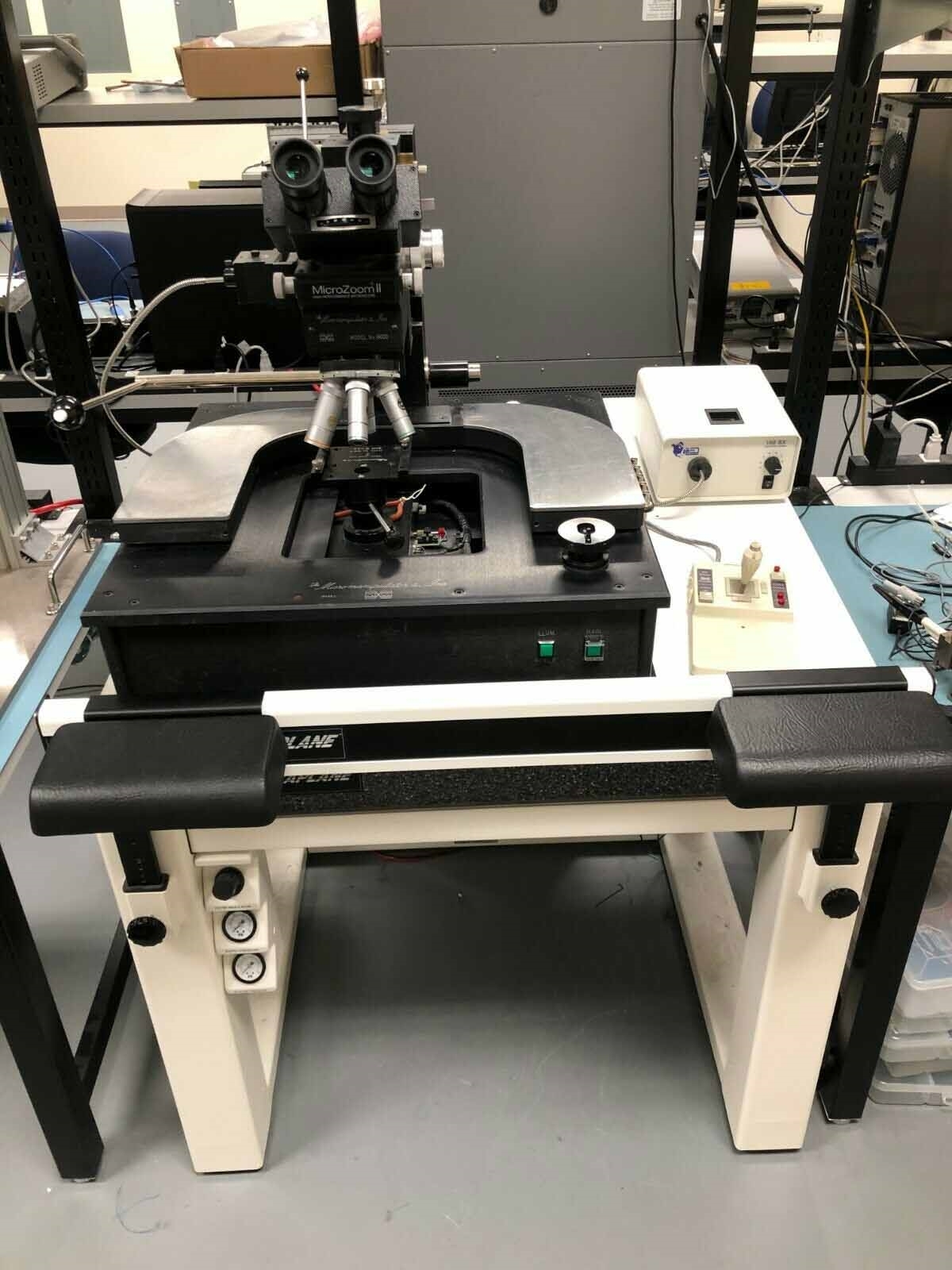

Used MICROMANIPULATOR 6600 #9272821 for sale

URL successfully copied!

Tap to zoom

ID: 9272821

Probe station

With isolation table

Includes:

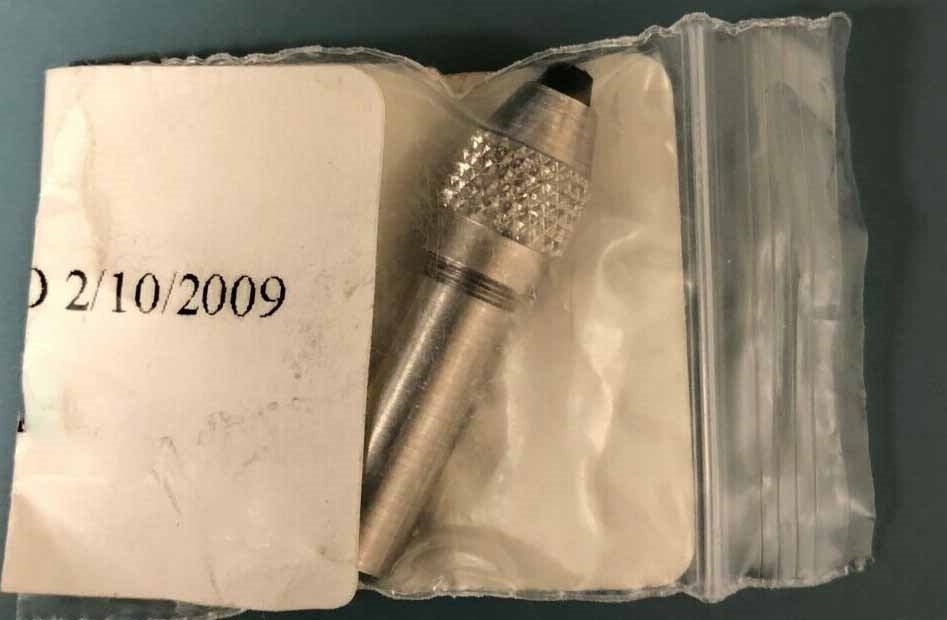

(6) Collet shaft assemblies

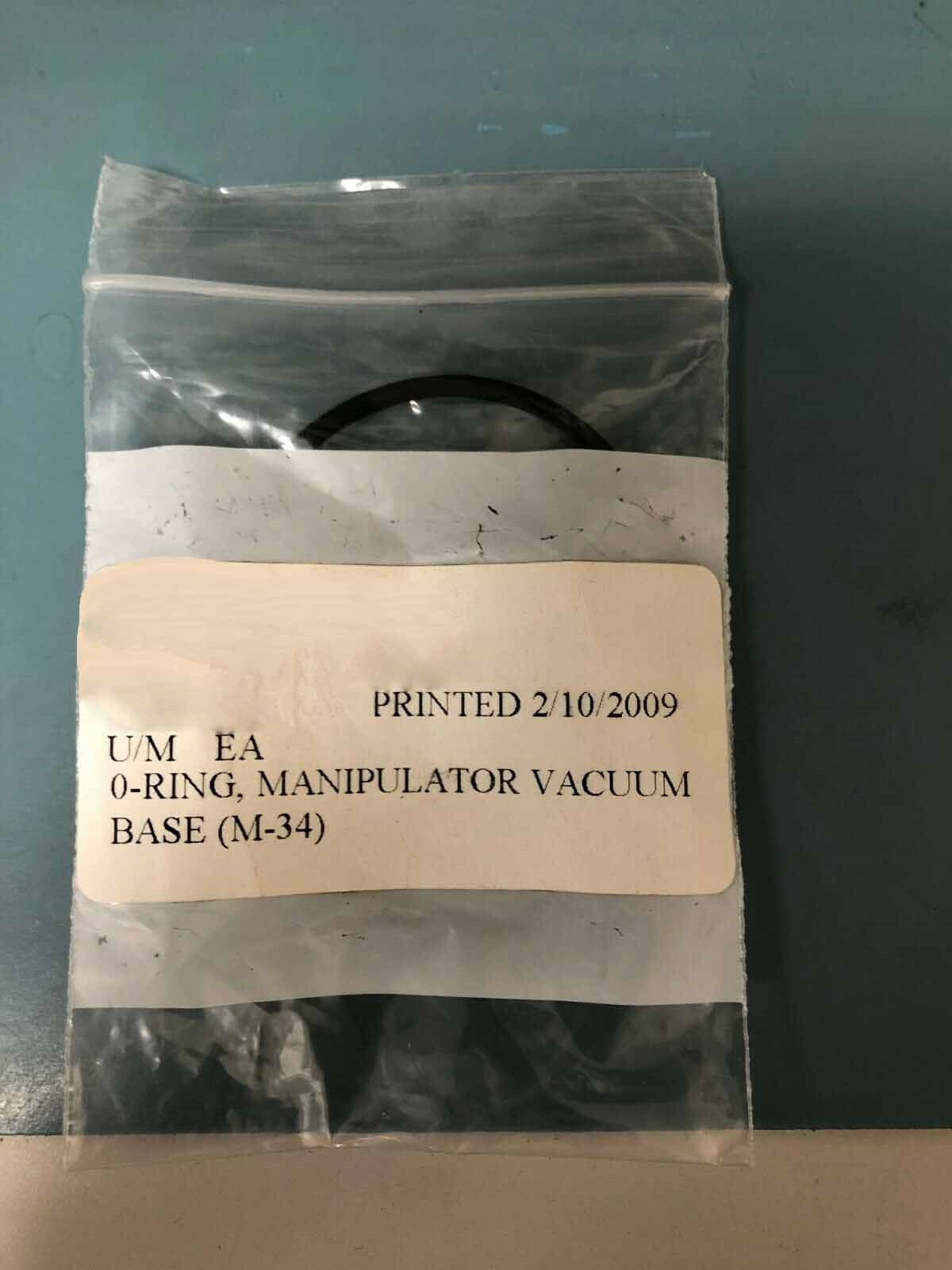

O-rings

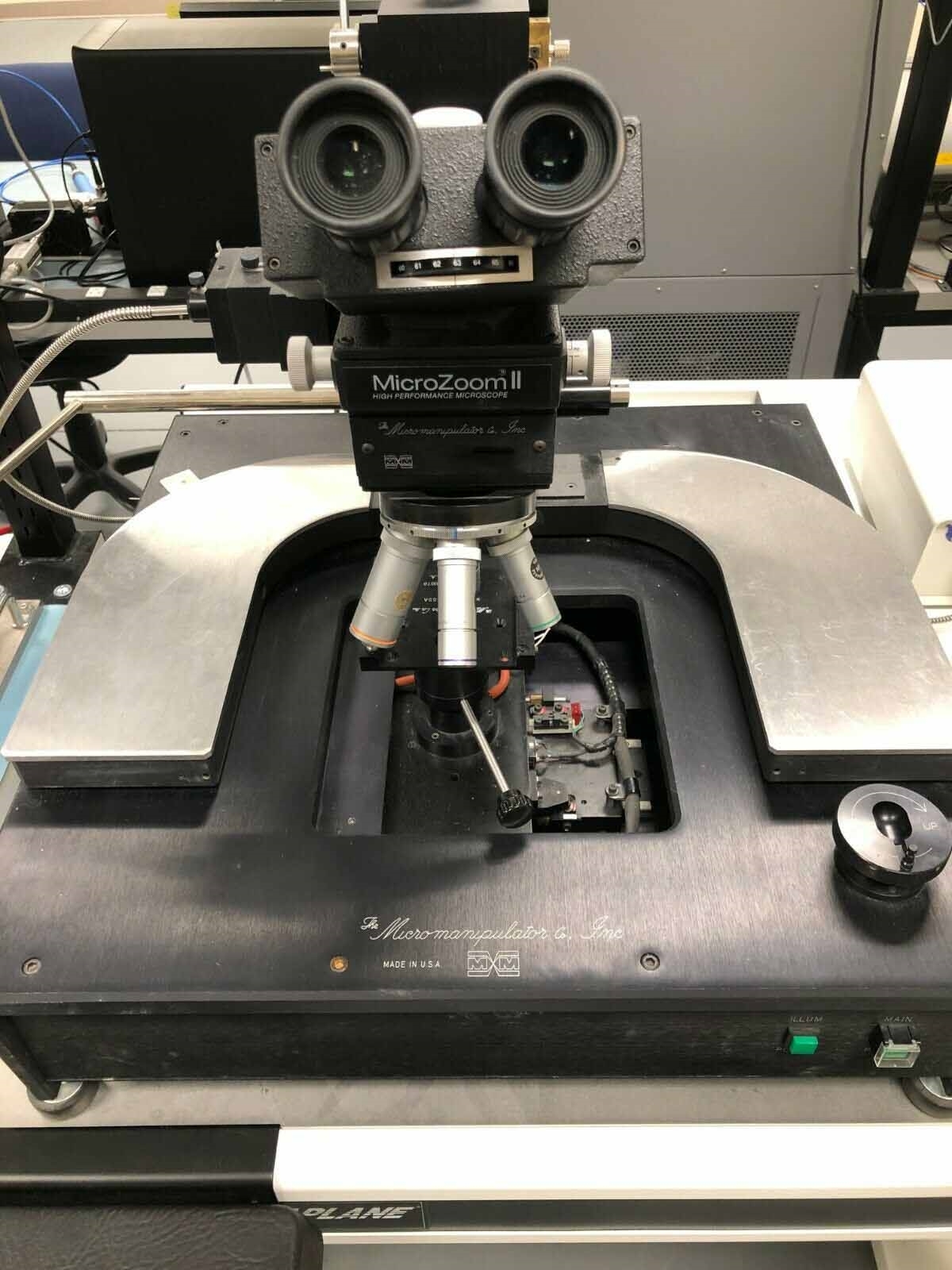

(2) MICROMANIPULATOR 450

(2) MICROMANIPULATOR 550

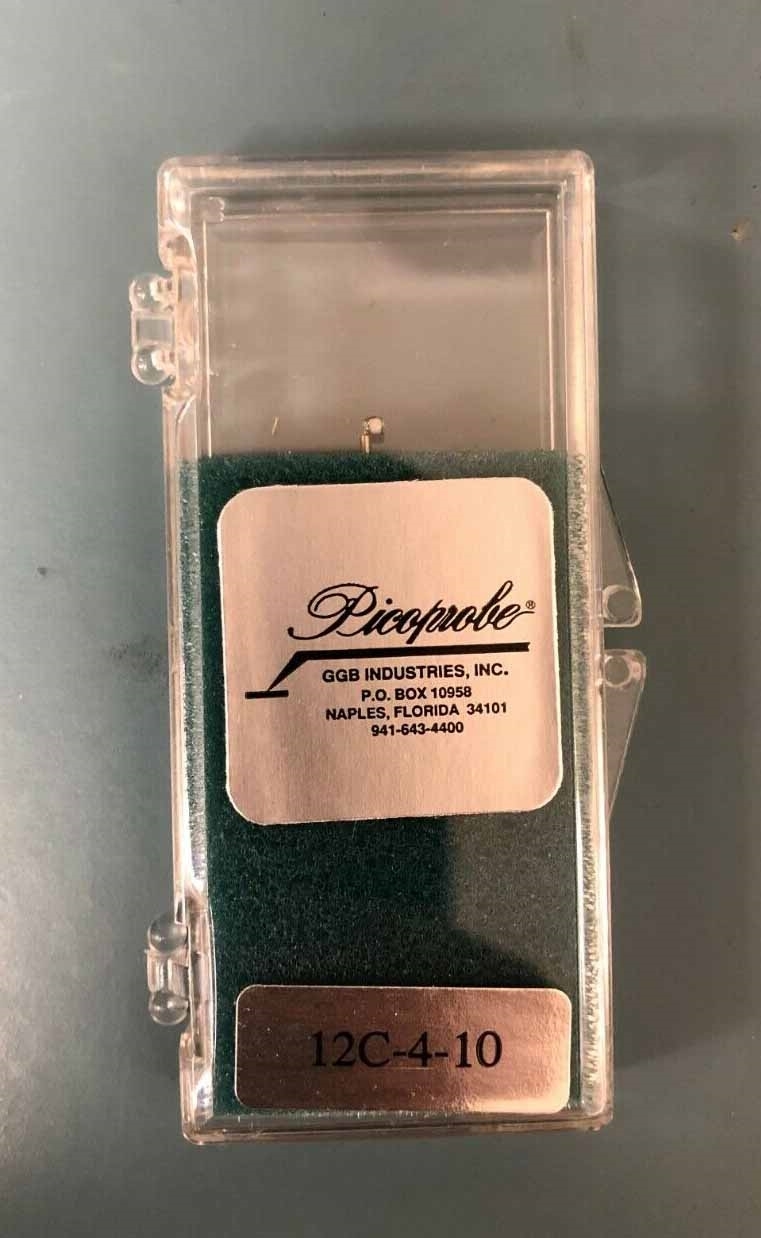

(35) Picoprobe tips:

12C-4-10

12C-1-22

12C-4-22

18B-4-20

18B-4-10

18B-4-20

(5) 12C and 18B picoprobes probe gain

Gomco vacuum for probe station

Air compressor for isolation table

Hot chuck

KINETIC Systems isolation table

With granite slab

(4) Picoprobe controllers

Objectives: 2.25x, 8x, 25x, 50x, 10x Eyepieces.

MICROMANIPULATOR 6600 is an advanced prober designed for use in advanced semiconductor process analysis. It is a highly accurate, high-performance platform that uses an array of built-in sensors to collect and analyze data from the semiconductor process. 6600 is capable of measuring and controlling the temperature of both the process environment and the substrates under test. It features three-channel temperature control, with temperatures ranging from -50 to +190 degrees Celsius. Onboard auto-calibration means repeatable analyses over time. It also has a low drift rate of ±0.05 °C, ensuring high accuracy temperature control. In addition to temperature control, MICROMANIPULATOR 6600 also features a wide range of other features designed to optimize process control and analysis. For example, its auto-sync and auto-focus functions allow for precise alignment of the prober tip with the feature of the substrate that is being measured. Auto-zeroing, auto-offsetting, and auto-coarse alignment ensure that accuracy is maintained over the lifetime of the equipment. 6600 also features an advanced scanning control system in which multiple probe heads can be synchronized to automate data acquisition. The unit can be configured for standard scan rate and fast scan rate for maximum capability. Additionally, sector scanning and skip scanning can be used to reduce the total amount of data collected. Other features of MICROMANIPULATOR 6600 include non-contact trip monitoring, precision lift control, 2-channel electron beam bias control, crash detection, and an alarm machine for critical process flow data and over-temperature protection. The tool is compatible with a wide variety of data formats, providing users with the ability to analyze results in a variety of ways. 6600 is a powerful tool for semiconductor process analysis. Its advanced control features, high precision sensor array, and wide range of features allow users to capture and analyze data in detail for optimal process control.

There are no reviews yet