Used MICROMANIPULATOR MM 9920 #9036111 for sale

URL successfully copied!

Tap to zoom

ID: 9036111

Wafer Size: 12"

Vintage: 2004

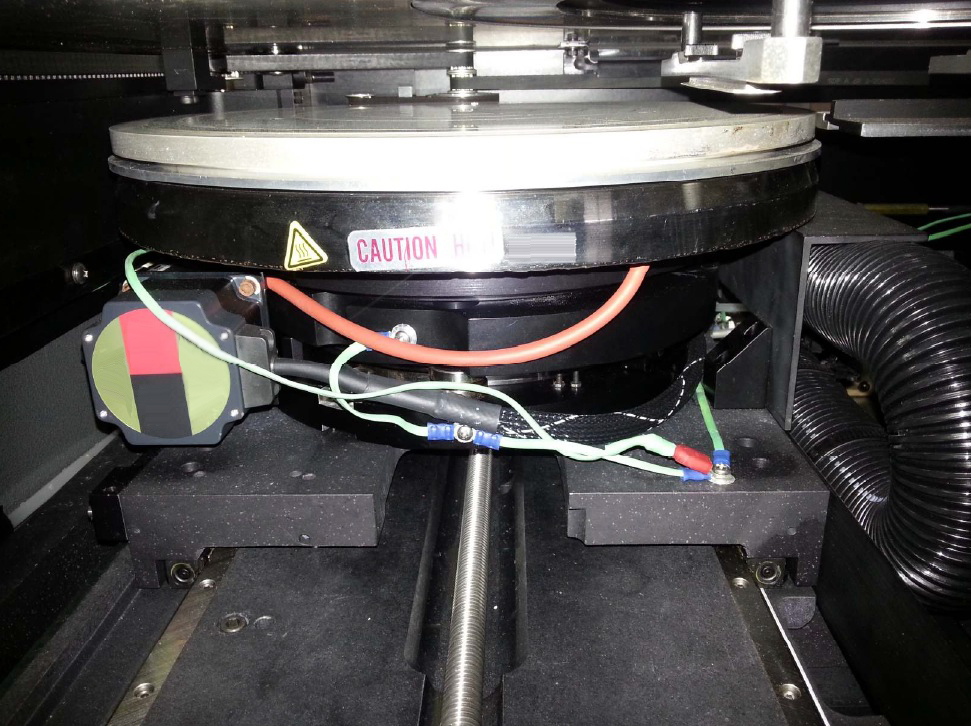

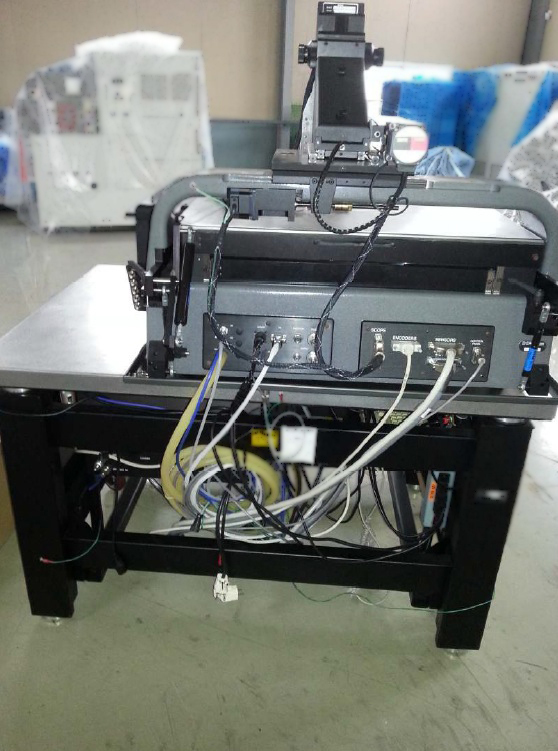

Semi-automatic prober, 12"

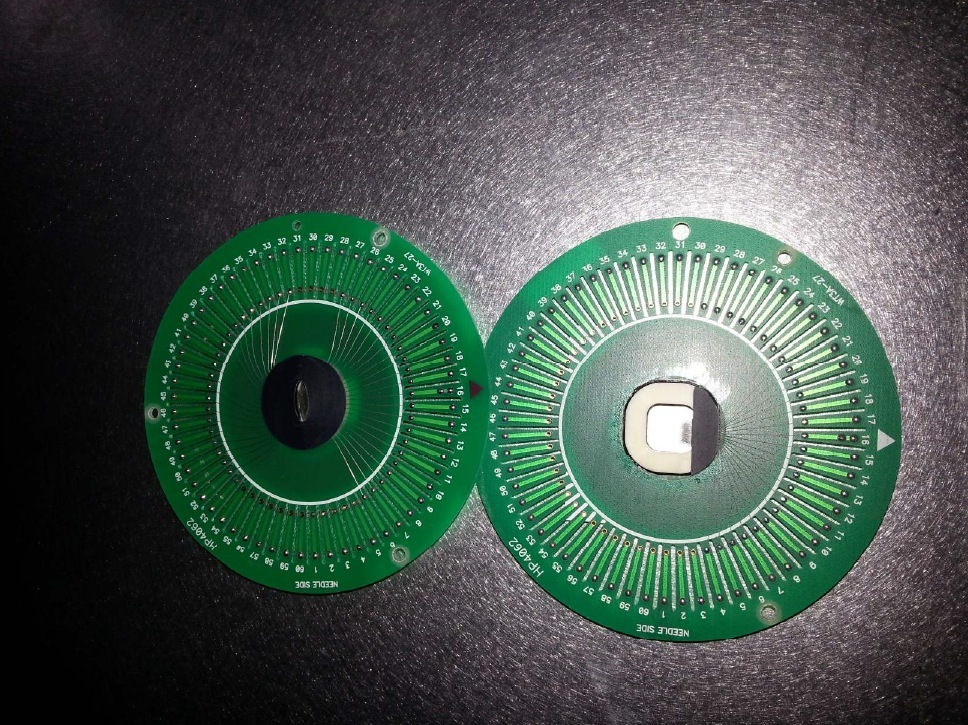

Chuck, 12"

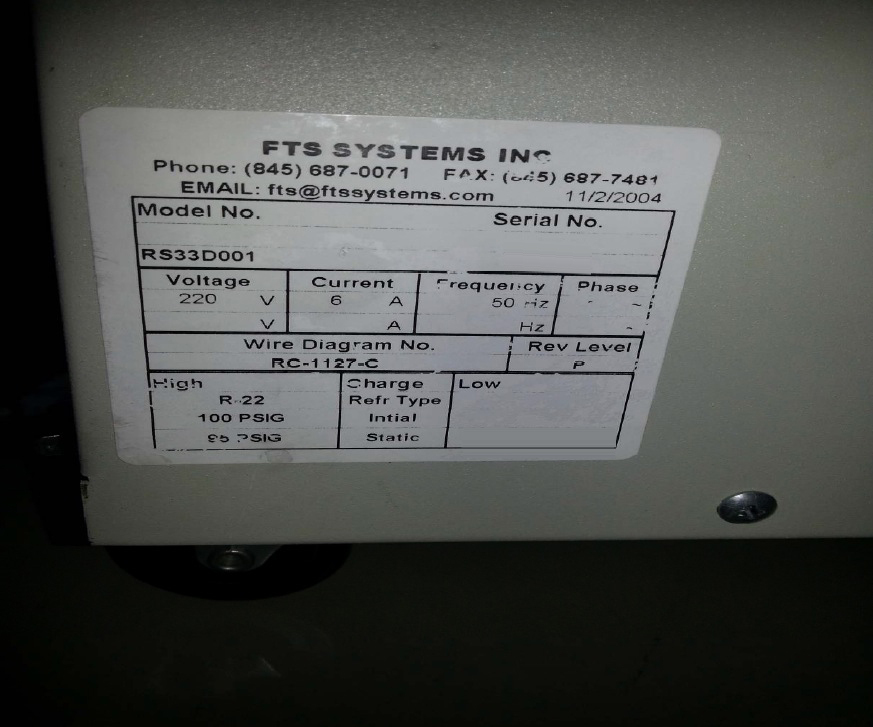

Tri-temperature option

Chiller

CDA, 100 psi

VAC, 25IN-Hg

H2O / Glycol, 2L, 6.1 LPM

60/40

Hard Disk Drive (HDD) missing

Power supply: 230 V, 50/60 Hz

2004 vintage.

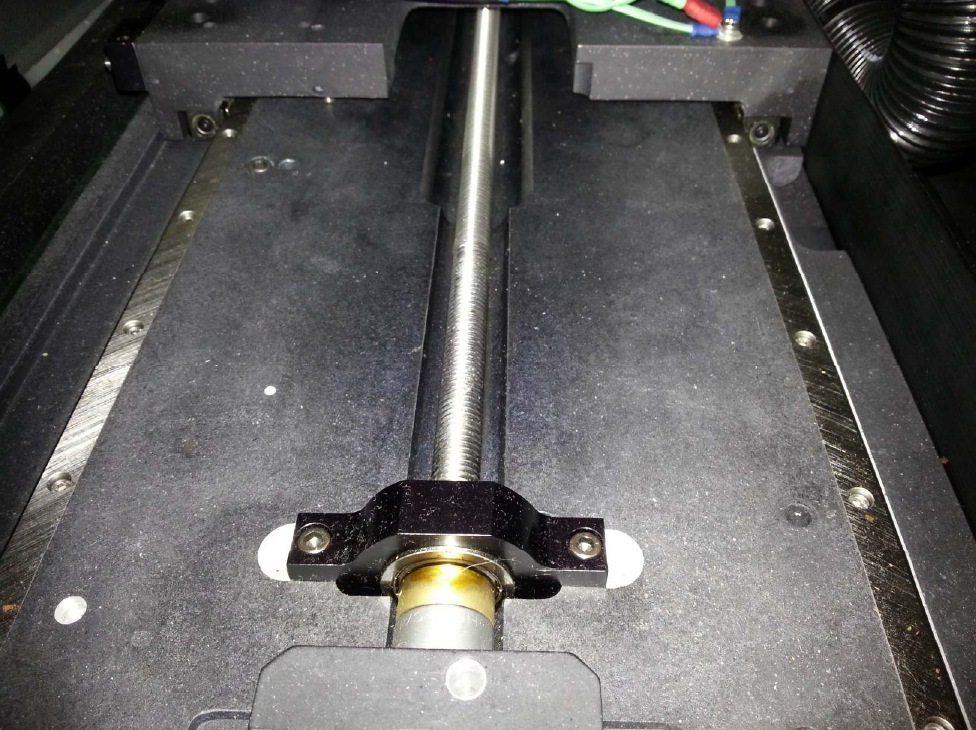

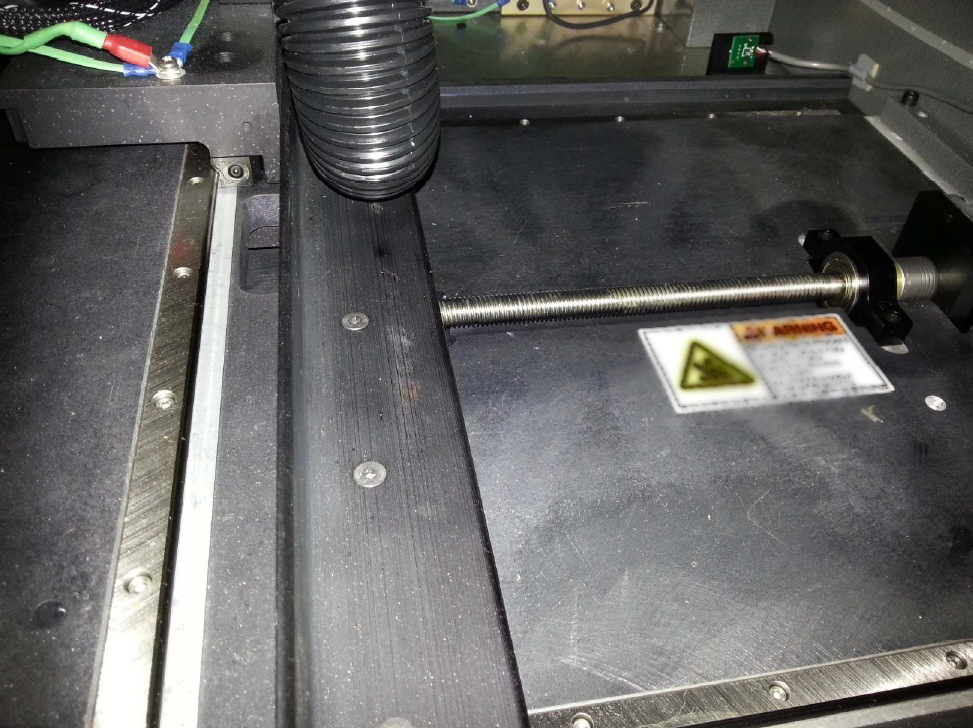

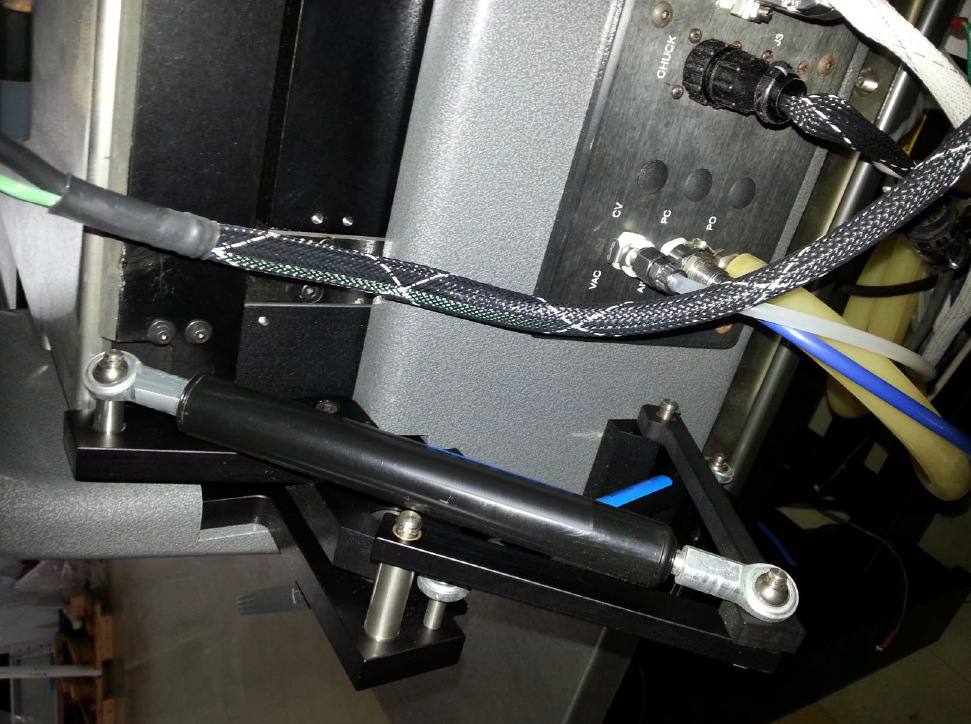

MICROMANIPULATOR MM 9920 is a high-precision, automated handling equipment used in semiconductor manufacturing. It is designed to precisely cut, place, align and handle wafers, components and other small surface mount devices. MM 9920 operates with a linear, high-resolution X-Y motion system, with a precision positioning accuracy of 1.0μm in the X-Y plane. It utilizes a closed-loop, high stiffness encoder and stepper motor control for precision movements in the Z-axis. MICROMANIPULATOR MM 9920 is capable of handling components with a wide range of sizes, shapes, weights, and materials due to its variable force capabilities. Force is adjusted using digital control software and can be programmed to precisely handle delicate components, such as exotic metals or fragile materials. The unit is designed with several standard operating functions, such as indexing (X-Y moves and rotations), cut/scissor actions, and pick-and-place operations. These functions provide the capabilities to accurately pick up, align, and place components onto a substrate during chip assembly. The manipulator is composed of various components, such as the mini-positioner (the X-Y linear motion machine), fine-positioner (Z-axis), digital force control, motorized actuators, and vision systems. The mini-positioner utilizes a pull-back mechanism to lock the wafer onto the positioner via an air nozzle and provide precise linear movement in X-Y direction. The actuators are used to move the components when a motion program is executed. The vision tool allows the asset to detect and recognize the features of the substrate, as well as detect misalignment in the process, preventing unscheduled stoppage due to an incorrect assembly. MM 9920 is designed for harsh industrial and manufacturing environments. It can handle extremes in temperature and humidity, as well as handle high-frequency vibration and shock environments. MICROMANIPULATOR MM 9920 is programmable through a graphical user interface. This allows the user to quickly and accurately program the sequence of operations required to complete a given task. It is connected to a central computer via a communications port for control, monitoring, and data logging. In summary, MM 9920 is a high-precision, automated control model used in semiconductor manufacturing to pick, place, align and handle wafers, components and other small surface mount devices. It features a high resolution X-Y motion equipment, digital force control, vision systems, motorized actuators, and a graphical user interface. It is designed to perform operations in harsh environments with precision and accuracy.

There are no reviews yet