Used SEMICS Opus II #9383808 for sale

URL successfully copied!

Tap to zoom

ID: 9383808

Wafer Size: 12"

Vintage: 2006

Wafer prober, 12"

Tempareture: Ambient/Hot

2006 vintage.

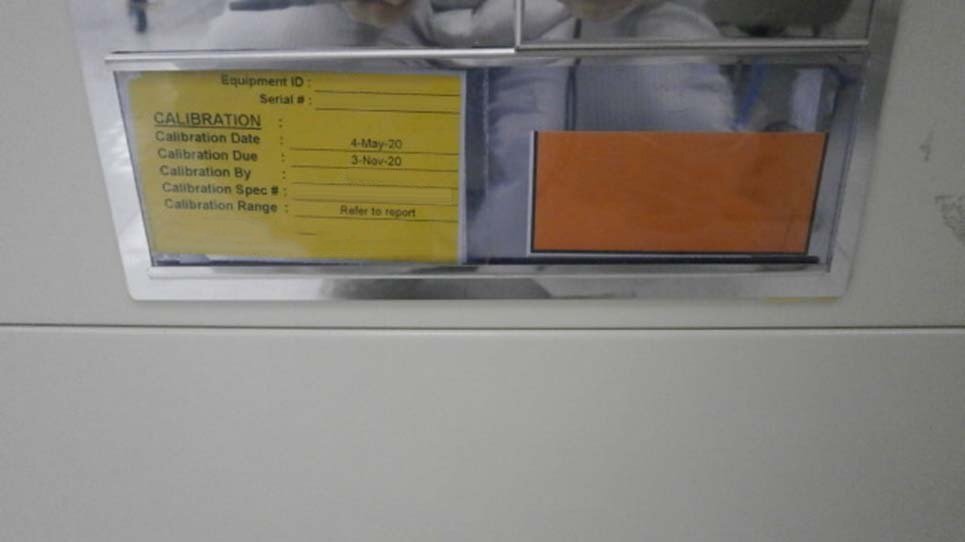

SEMICS Opus II is a prober used in the semiconductor production line. It is designed to rapidly, accurately, and precisely create devices and process them in multiple layers. The prober is a fully automated system that uses a variety of tools such as contact scanning probe microscopes, advanced imaging systems, and machines such as micro-probing and electrochemical potential probes. These tools allow for a wide variety of inspection, analysis, and industry-standard testing. Opus II prober provides specific capabilities to meet specific production requirements. It offers automated positioning and precision alignment of a wafer to the probing stage, robotic wafer handling, and wafer moveable loading. The robotic wafer handling system operates in an enclosed environment, allowing movement between wafer chucks and the scan probe. The contact scanning probe microscope utilizes a variety of advanced imaging techniques and offers a 22-nanometer resolution and vertical image resolution of 2.5 nanometers. SEMICS Opus II also utilizes a retractable probe tip coupled to a specialized calibration device for accurately measuring surface potentials. This allows for non-destructive testing of materials and/or devices. In addition, the prober is able to automatically analyze stored images to identify and characterize components or defects. The automated machine is also able to perform circuit measurements such as resistance, current, voltage, IMD, current leakage, high voltage, and thermal analysis. This advanced prober is designed for use in the fabrication and production of semiconductor parts. Opus II provides an optimal platform for high-speed testing of components and material. It offers comprehensive automated wafer loading, handling, and analysis capabilities that can keep up with demanding production volume. The prober is designed with a versatile feature set that is capable of handling and measuring components in production. Its ability to analyze stored images and to perform automated measurements provides an excellent platform for high-speed testing of components and material.

There are no reviews yet