Used TEL / TOKYO ELECTRON P-12XL #293618550 for sale

URL successfully copied!

Tap to zoom

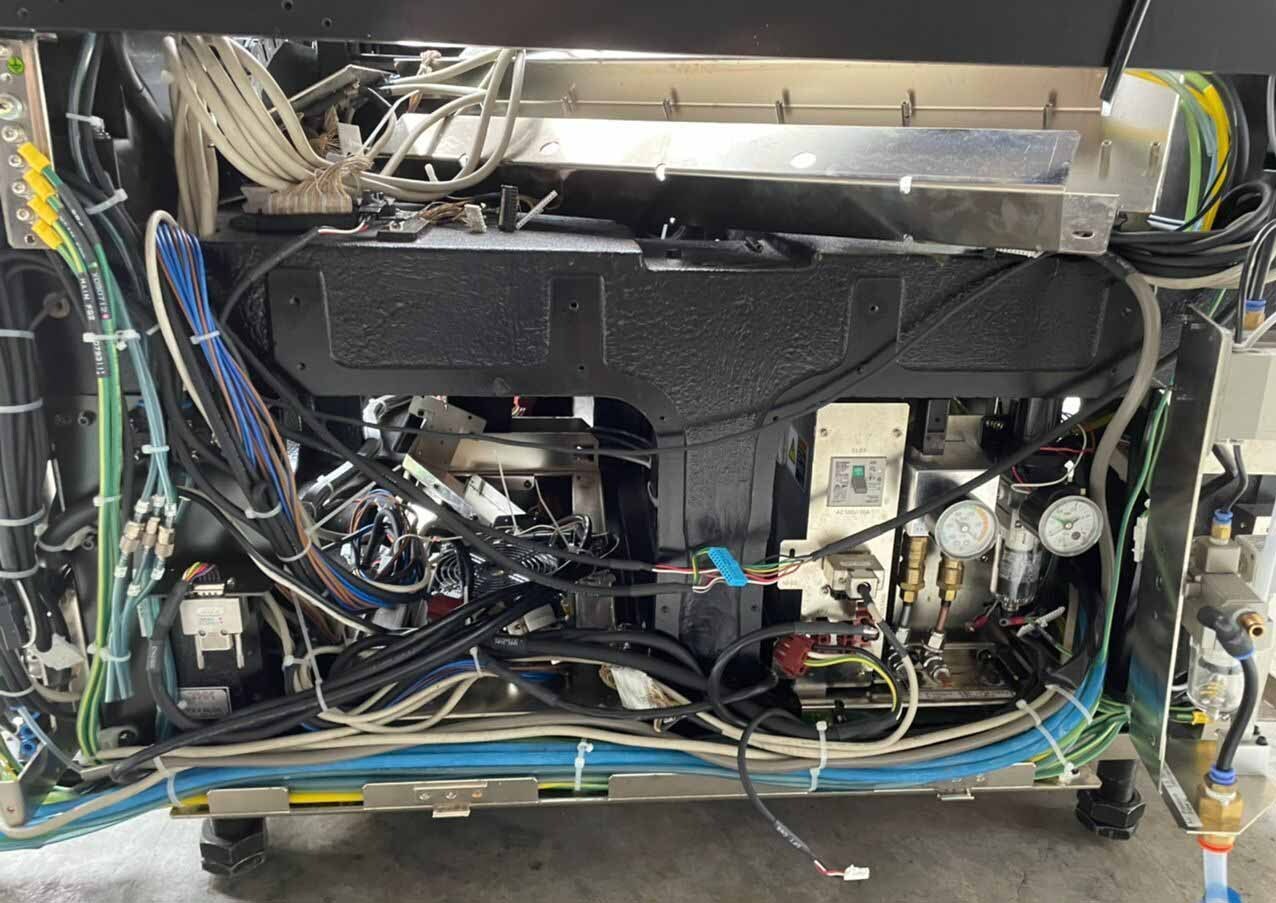

TEL / TOKYO ELECTRON P-12XL prober is a precision tool used in the semiconductor fabrication industry to help ensure the performance and reliability of semiconductor wafers. The prober uses an operating equipment that utilizes a 3-stage temperature control system, with three independent temperature sensors to provide high precision and accuracy over large areas of wafers. The unit also has a large usable area of 1000mm x 800mm, allowing the prober to inspect and identify any potential defects and irregularities on the wafers before they are further processed. TEL P12XL prober is equipped with a high-precision stage control and accuracy to ensure defect recognition and measurement accuracy over wide areas, without any misalignment. It has XY, UV, and five-axis stages for scanning and process control, with an XY-Drive position repeatability of 0.01µm and a Z-Drive position repeatability of 0.001µm. Moreover, the prober has a position accuracy of ±0.01mm over a large area, essential for defect mapping. TOKYO ELECTRON P 12 XL prober also has an advanced real-time tracking machine for automated defect recognition and repair. This tool allows for a fast defect detection process, utilizing hardware and software damage recognition, 2D laser and 3D scanning, and a high-resolution imaging asset. This ensures that any defects found on the wafers are quickly and accurately identified, allowing the user to react quickly to any defect conditions or irregularities. TEL P-12 XL prober is an ideal tool for the semiconductor fabrication process, providing high accuracy and precision to ensure the reliability and performance of semiconductor wafers. With its advanced real-time tracking model and precision stage control, P-12 XL prober can detect and identify any potential defects quickly and accurately, making it an invaluable tool for ensuring semiconductor manufacturing quality control.

There are no reviews yet