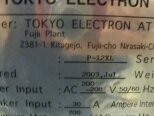

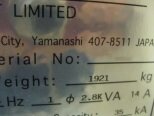

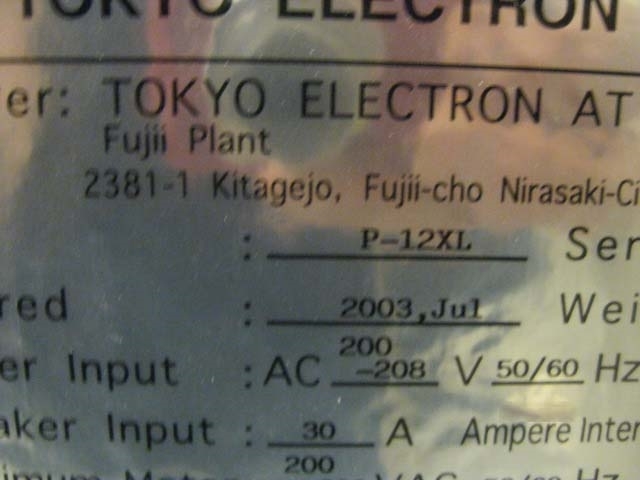

Used TEL / TOKYO ELECTRON P-12XL #9254711 for sale

URL successfully copied!

Tap to zoom

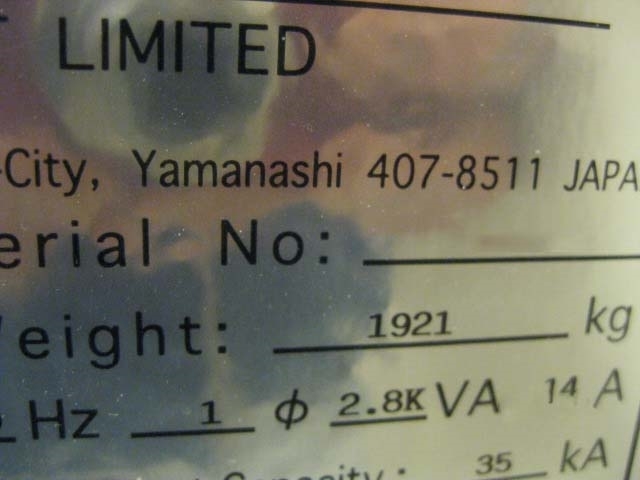

ID: 9254711

Vintage: 2003

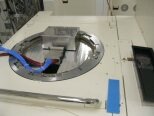

Wafer prober

XY Probing accuracy: ±4.0 μm

Z Probing accuracy: ±5.0 μm

Probing force: 100 kg

Optical system: ASU/BCU-I

2003 vintage.

TEL / TOKYO ELECTRON P-12XL Prober is widely used in semiconductor analysis and test. It is designed to quickly and accurately deliver quality data for a range of products, from low-end to high-end. It delivers reliable wafers and die performance data to the maximum. TEL P12XL Prober is an automated systems solution for probe testing and device level measurements. The precision prober features an advanced motion control with high speed, accurate positioning and repeatability. The 12"x 12" prober enables the easy positioning of die onto the 12" x 12" test pattern area. Quick and accurate data for a range of products are guaranteed by the prober's precision probing EDM (electrical discharge machining) technology. TOKYO ELECTRON P 12 XL Prober offers a full range of wafer and die testing capabilities including die probing and full wafer level probing. Its powerful wafer level precision prober is capable of accurately inspecting and probing different types of electrical devices, such as DRAM, SRAM, SRAMC, ROM, DRAM Memory cards and on-board Semiconductors. TEL / TOKYO ELECTRON P12XL Prober features an easy-to-use graphical user interface with a wide variety of functions. The user-friendly design allows for the programming and testing process to be performed quickly and accurately, while the display offers full visualization of the die or wafer under test. The prober is completely automated and ensures reliability by providing detailed statistical information. The quality system ensures accurate and repeatable data in every test cycle, while the interchangeable wafer test head enables complex probing configurations. P-12 XL Prober is also equipped with advanced analytical software for testing and simulation, ensuring the most accurate and reliable measurements of die and wafers. The flexibility of system hardware and software are tuned to produce the highest accuracy data in the shortest time. This leads to higher quality and no failure rate for any production, process or device.

There are no reviews yet