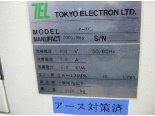

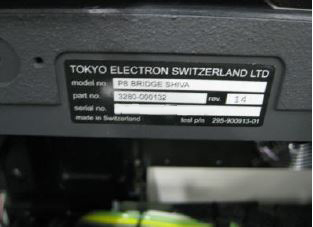

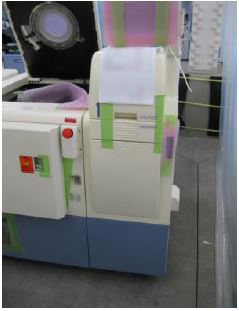

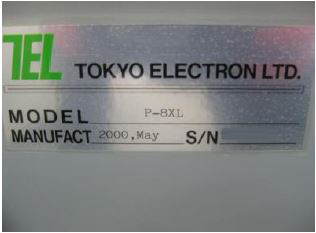

Used TEL / TOKYO ELECTRON P-8XL #9131758 for sale

URL successfully copied!

Tap to zoom

ID: 9131758

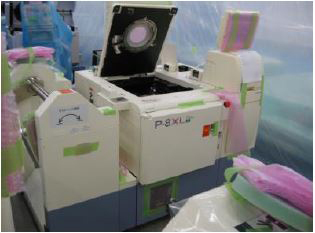

Wafer Size: 8"

Vintage: 2000

Prober, 8"

Hot

200v

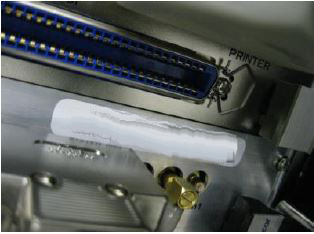

Power Cable

Head plate

Gas-spring on headplate

Standard monitor

WAPP-10K with brush

Card Holder

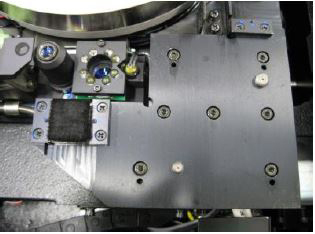

Manipulator

Wafer Table

SACC: 200/300

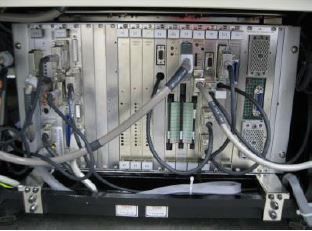

Boards:

147-CON

VIP3

GP-IB

TVB9003-1316

QMC#0

QMC#1

DMC3#2

TESTER

I/F

M-1

M-2

LST-1

LST-2

PST-STD

PST-OPT

SIO

2000 vintage.

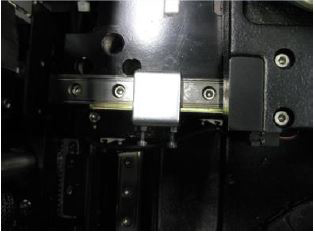

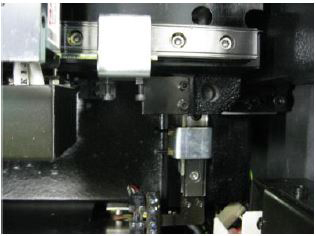

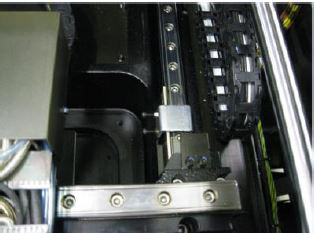

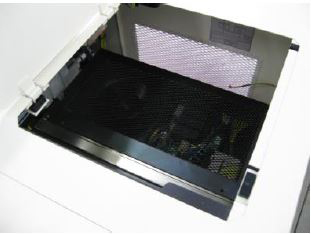

TEL / TOKYO ELECTRON P-8XL Prober is an automated wafer probing equipment designed to test, characterize, and inspect semiconductor chips and wafers. It is equipped with an advanced die handling system, accurate probing positioners, and a high-resolution optical diagnostic unit. The machine provides an ideal platform for characterizing integrated circuits (ICs) at the wafer level. TEL P8XL is a fully automated prober tool that can handle various wafer sizes and types. It is integrated with an integrated dual-axis robotic material handler (X-Y "Xacta" positioner) for efficient wafer transfer. It can accommodate wafer sizes from 4" to 8" with optional adapters. The dual-axis robot handler can move the wafer precisely from storage Site to test area, and back onto the storage site quickly and accurately. TOKYO ELECTRON P8-XL Probe asset is equipped with a high-resolution optical microscope for die characterization and wafer mapping. This microscope enables the inspection and analysis of wafer surfaces and structures. It has a motorized stage that can be operated via software for panoramic visualization of a wafer or die during testing. The microscope also has a high-sensitivity video camera for capturing images for analysis. The automated testing feature of TEL P8-XL prober is enabled by its Probe Drive Unit (PDU). This microscopic, programmable probe adjusts the probing position and angular orientation throughout the testing process, ensuring the accurate and repeatable testing of each chip in the wafer. The PDU also handles automated wafer handling model for sample loading into the prober. Furthermore, the PDU is integrated with various chip testers and testing probes, offering the capability to acquire accurate electrical parameters from each chip. TOKYO ELECTRON P-8XL also has advanced motion control systems for precise positioning of wafer sites. Its programmable air pressure controller ensures the optimal pressure for contact between the probe and the surface of the die. TOKYO ELECTRON P 8 XL prober is able to perform repeatable, high-precision measurements for process development, wafer sort and production testing. It is used in many different industries such as consumer electronics, automotive, biomedical, and material sciences.

There are no reviews yet