Used TEL / TOKYO ELECTRON P-8XL #9131783 for sale

URL successfully copied!

Tap to zoom

ID: 9131783

Wafer Size: 8"

Vintage: 1999

Prober, 8"

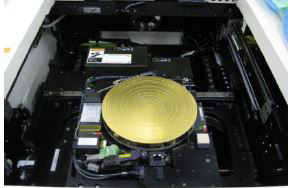

Gold

Hot

200v

GP-IB Cable

Head plate

Gas-spring on headplate

Standard monitor

WAPP-10K with brush

Card holder

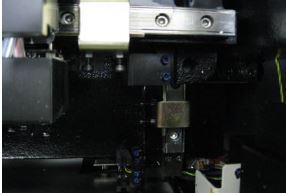

Manipulator

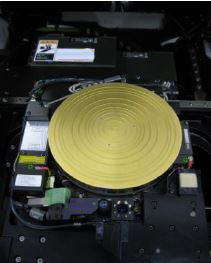

Wafer table

Printer

SACC: 200/300

Boards:

147-CON

VIP3

GP-IB

TVB9003-1316

QMC#0

QMC#1

DMC3#2

Tester

I/F

M-1

M-2

LST-1

LST-2

PST-STD

PST-OPT

SIO

1999 vintage.

TEL / TOKYO ELECTRON P-8XL is a fully automated wafer prober designed to help reduce production costs and increase throughput for Thin Film Transistor Liquid Crystal Display (TFT-LCD) production lines. The prober is a fully automated tool with a closed-loop feedback equipment for precise overlay registration and fast loading and unloading of wafers. It is designed for high throughput technicians with fast loading and unloading time, quick set up times, and the ability to easily switch between wafer sizes or even wafer type. TEL P8XL utilizes a built-in XY motor and encoder to accurately centralize the wafer and keep it stationary while the probe pin is moved into contact with the wafer. Its auto-calibration and re-alignment system ensures the highest accuracy of measurement and records the exact position of each finger location and pattern size, creating an accurate map of the circuit pattern. It features a fully enclosed bed and powerful air-cooling unit which remove heat and reduces sample contamination. The prober also includes a user-friendly graphical user interface (GUI) allowing for efficient and intuitive operation. Multiple wafers can be loaded to improve the throughput of a few wafers. Additionally, it has a user-defined macro program language that can be used to manually input specific positions and settings. This user-defined macro program language adds flexibility to the prober and allows the user to customize the settings or parameters for TFT-LCD application. TOKYO ELECTRON P8-XL prober is a high performance and reliable solution for TFT-LCD production lines. It is capable of handling thin film deposition, transfer and test operations with precise overlay registration, fast loading and unloading times, and quick setup times. The automated machine and user-defined macro program language increase the customization for the production line, helping to reduce production cost and improve throughput. With its low maintenance and quality assurance features, P-8 XL is the perfect solution for production lines of TFT-LCD modules.

There are no reviews yet