Used TEL / TOKYO ELECTRON P-8XL #9168299 for sale

URL successfully copied!

Tap to zoom

ID: 9168299

Vintage: 2002

Probers

Hot chuck

Gold chuck

Hot chuck controller

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD)

Single cassette

Fail mark inspection

Needle inspection

SACC

Marking by category

Auto needle alignment

Auto needle height

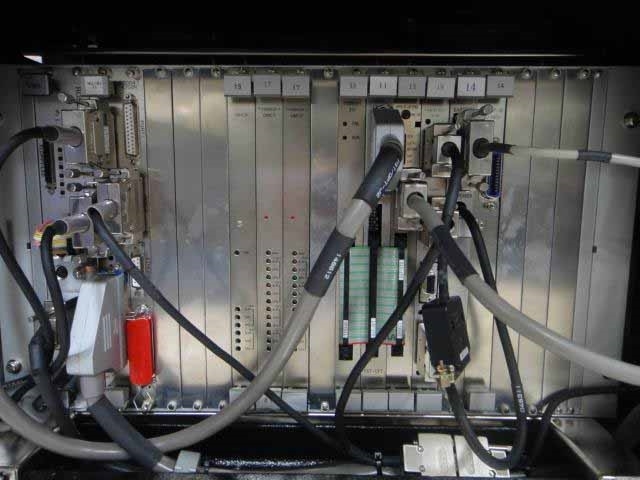

GP-IB

WAPP (Cleaning option)

Chuck type: -40°C~150°C (Chiller model: D214)

Group index

Configuration disk

Signal pole

Function check

VIP Version: VIP3

LST1 / LST2: Version 14/15

No TTL

No RS232

No offsite marking

No menu

No TTL cable

No GP-IB cable

No marker unit

No OCR

Voltage: AC 200 V

2002 vintage.

TEL / TOKYO ELECTRON P-8XL is a prober used to create a uniform and flat surface topography and metrology of advanced technology devices. It is designed to measure and map micro-scale surface profiles of substrates, or chips, for a range of probing applications such as automotive, medical, consumer, and industrial products. TEL P8XL accomplishes this complex task with a highly precise, high-resolution die-tensioning system, allowing for pinpoint accuracy on the smallest of substrates and products. The die-tensioning system consists of three main components: the die-tensioning heads, the die-tensioning roller, and the die-tensioning actuator. The tensioning heads allow for precise control over the application of pressure and torque during the step of die measurement. This is critical to ensure the accuracy of measurements in the product development stages. The tensioning roller/arm provides an additional layer of control over the outputs of the tensioning actuator. The die-tensioning actuator-focusing stage is at the core of the prober. It consists of input signals from the heads, rollers, and the actuator itself, generating outputs to the die-tensioning piezo-electric actuator. This stage works to ensure that the force and pressure is precisely consistent and uniform across all areas of the die-tensioning surface. The die-tensioning actuator is detailed in-depth and includes the benefits of TOKYO ELECTRON P8-XL's ability to generate precise and consistent pressures, sizes, shapes, and topography of the die-tensioning surface. This is done through the use of various Piezo-electric Actuators, allowing the user to adjust the topography of the substrate and chips on a wide range of conditions such as pressure, temperature, and material composition. Overall, P-8 XL is a complex piece of equipment. It acts as a precise and accurate tool for obtaining precise surface topography and metrology results. TOKYO ELECTRON P8XL's piezo-electric actuators, die-tensioning heads, and die-tensioning rollers allow for the user to properly adjust and control the surface of the substrate or chip for a variety of applications. This device can be used to map high-precision surfaces of die and chips used in a variety of industries.

There are no reviews yet