Used BTU Pyramax 125N #9165778 for sale

URL successfully copied!

Tap to zoom

ID: 9165778

Vintage: 2010

Reflow oven

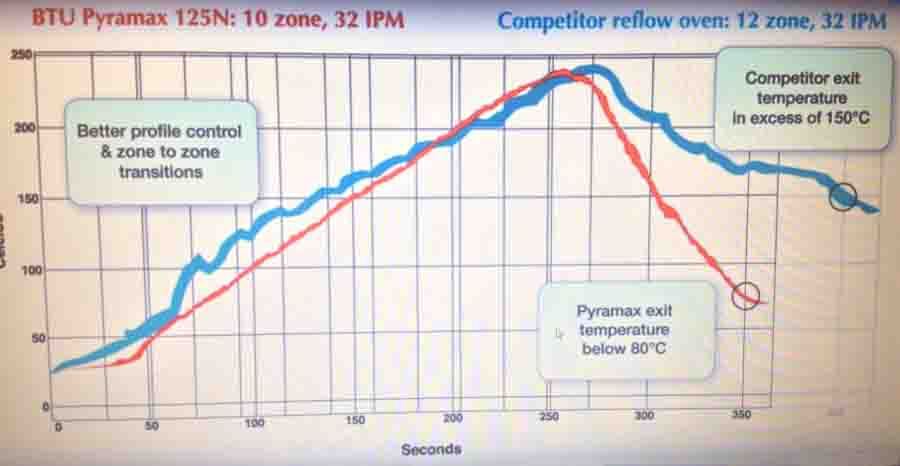

(10) Heated zones (top & bottom)

(2) Cooling zones

Constant heat transfer

Reduced Nitrogen consumption

Low power consumption

Forced impingement convection

Programmable heating & cooling rates

Side to side gas recirculation

Automatic width adjust

Conveyor width: 2-18 inches / 51mm - 457mm

Speed: 10-60 inches/min / 25-152 cm/min

Dynamic gas idle

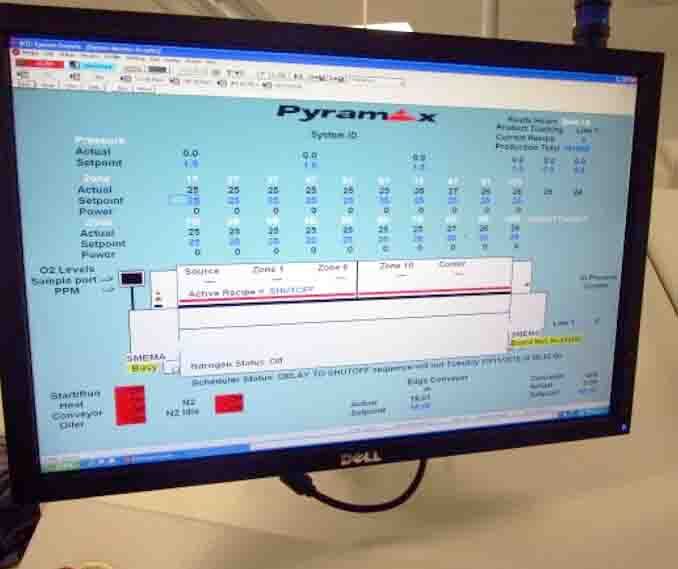

WINCON Control software

Heated length: 125inch / 3175mm

Power: 3 Phase, 480V, 111 Amp, 93Kva 50/60Hz

Options:

Rail/Belt combination (0.190in/4.8mm pin)

Programmable width adjust

Smart tracker SMEMA

Light tower

Closed loop convection control

Bottom water cooling modules (125 systems)

Recirculating water supply-internal (double color)

Dynamic N2 idle

Auto-gas sampling

Oxygen analyzer (PBI dansensor mapcheck with display)

Nitrogen on lamp

2010 vintage.

BTU Pyramax 125N is an advanced reflow oven that offers consistent, repeatable, and reliable reflow soldering of surface mount components onto printed circuit boards. It is designed to meet rigorous Total Quality Management (TQM) standards for electronics manufacturing and is ideal for high-volume, precision manufacturing environments. BTU PYRAMAX 125 N is equipped with dual, independently-controlled systems, including a UL-certified LN2 cooled Nitrogen Atmosphere Reflow equipment. The dual-system capabilities enable the oven to provide maximum flexibility in controlling the reflow process to suit varying component or board macro-topology requirements. The oven can also quickly and easily be switched out from one unit to the other with a simple menu selection. The oven features an adjustable air flow machine, controllable to within a sub-degree of accuracy, for improved temperature uniformity and board-to-board reproducibility. The air flow tool minimizes turbulence and improves surface mount component coverage. The oven also features a fully customizable reflow profile with up to 32 programmable segments. Advanced electronic flow control and monitoring capabilities help improve the consistency of the reflow soldering process and ensure optimal results. The temperature control asset utilizes a closed-loop, heat-seeking PID model with non-contact type PID thermocouples. The thermocouples measure temperature on the top, bottom, and lead sides of the reflow oven. The oven is also designed to meet stringent vapor recovery standards for protecting the environment. Pyramax 125N is equipped with an easy to use control equipment and LCD touchscreen display. User-friendly software provides a secure, intuitive graphical interface with a library of professionally engineered profiles. The oven also features an advanced monitoring system for continuously monitoring the process and troubleshooting any errors. The oven's sophisticated design also features a secure, safe, and efficient operation. It is protected by an integrated, self-monitoring thermal cut-off device that provides extra safety and prevents product or personnel injury that may result from an incorrect nitrous dioxide or PCB level. This unit also monitors the internal environment for potential temperature drift or mechanical defects. PYRAMAX 125 N is a powerful and sophisticated reflow oven that offers reliable, consistent, precision soldering of components onto boards. It is ideal for high-volume production lines and meets rigorous TQM standards for electronics manufacturing. It offers the latest technology with adjustable air flow systems, temperature control, and advanced monitoring to ensure optimal results.

There are no reviews yet