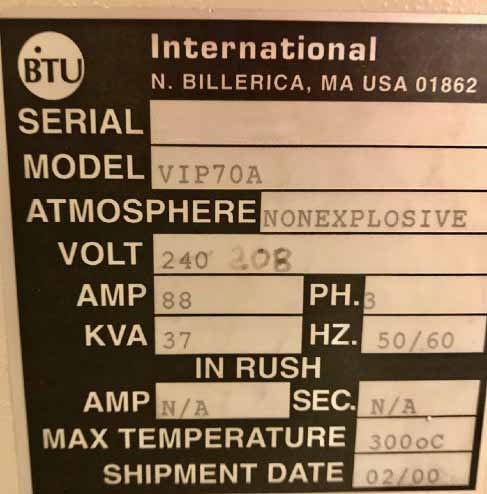

Used BTU VIP-70A #9215546 for sale

URL successfully copied!

Tap to zoom

ID: 9215546

Vintage: 2000

Reflow oven

(5) Zones

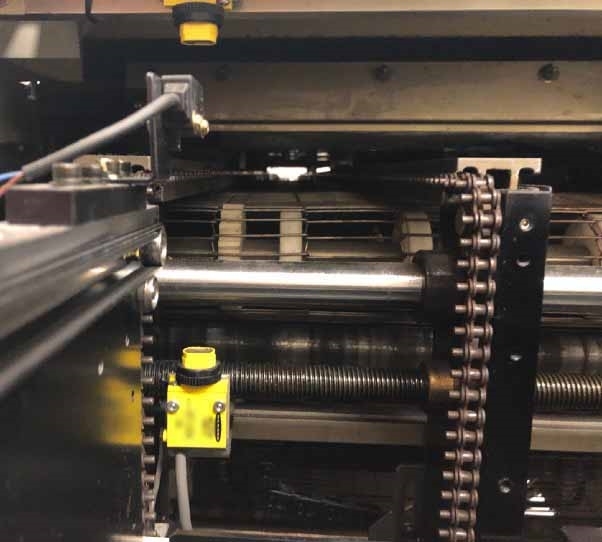

Edge pin, 18"

Chain mesh belt, 22"

Maximum temperature: 300°C

Power supply: 208V, 88 A, 3 Phase, 60Hz

2000 vintage.

BTU VIP-70A reflow oven is an advanced production tool used to heat solder joints on circuit boards. This tool is constructed with high-quality components that benefit from precise temperature control, which is essential for providing a quality finish. The oven has advanced pressure sensors that provide fast and exact temperature profiling, allowing the user to make adjustments as the board moves through the oven tunnel. The oven can also detect solder paste thickness, which eliminates the need for manual measurement. This oven features an infrared radiative heat source, providing maximum reliability with minimal energy consumption. VIP-70A has four independent heating zones and contains an advanced gas-injection equipment that is used to control the reflow process. The flames, which can reach temperatures up to 600 degrees Celsius, are evenly distributed throughout the oven, allowing for precision and accuracy with each reflow cycle. This model is also equipped with a four-zone split-level conveyor system. This unit allows boards to be loaded and unloaded efficiently and accurately. The conveyor machine also helps feedback control, as it monitors the travel speed of the board through each zone. This ensures consistent heat can be applied to all the solder joints. The oven can be programmed to accommodate different lead-free alloys, allowing for flexibility when dealing with a variety of board configurations. BTU VIP-70A also offers settings for controlling the flux vapor created during the reflow process, reducing the risk of residue contamination. The exhaust fan can be programmed to remain on even after the reflow process is complete, helping to remove any lingering fumes from the oven chamber. VIP-70A is user friendly, with an easy to use control panel supplemented by an on-board observation window that assists the process. This reflow oven is built with advanced safety features, providing both the operators and the unit itself with protection from overload, overheating and short circuiting. This oven is ideal for automated production lines and achieves optimum results with minimal operator intervention.

There are no reviews yet