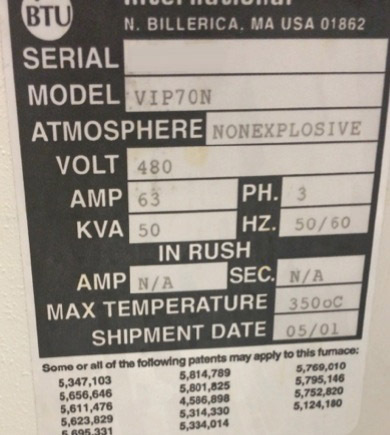

Used BTU VIP-70N #9059188 for sale

URL successfully copied!

Tap to zoom

ID: 9059188

Reflow oven

Max. temp.: 350ºC

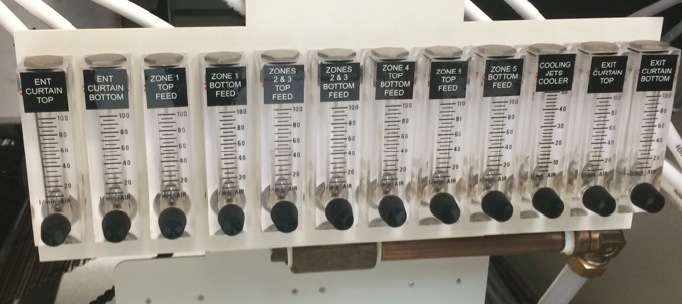

(5) Zones: (1) cooling zone

Nitrogen ready

18" edge and mesh belt with oiler

Upgraded WINCON 5.0 software and Intellimax control board: not currently installed

Manuals

Currently in cleanroom

Shipment date: Q2 2001.

BTU VIP-70N is a conveyorized reflow oven suitable for automotive and surface mount technology (SMT) electronic assembly applications. It features a precise temperature profile that is capable of producing the best quality solder joint. The oven is powered with natural gas or propane, and can be installed to accommodate various production throughput requirements. The main features of BTU VIP 70N include an up-front LCD panel for user settings, a temperature profile library, and a PID temperature control equipment. This oven has a nominal top temperature of 350°C, and a nominal belt speed of 454 to 610mm/min. It features a trilaterally sealed door designed for efficient heat retention, while also providing a tightly controlled chamber environment. The oven itself is composed of a heavy gauge sheet metal, with a high-temperature aluminized roof-liner, and stainless steel screw-in fasteners. The oven's burner system includes a pilot pilot to maintain consistent output throughout the reflow process and flame rods to ensure long-term control of the heating elements. The over also contains two modulating air blower fans that provide airflow control for efficient temperature control. The Zone III control unit can be programmed to accept up to 10 layered profiles for multiple product variations. The oven is equipped with two top-mounted infrared panels with 10 separate temperature sensors that monitor underneath the belt. It also includes four zone-divided fans which cycles air to provide a uniform heating of the product and board surface. The oven features a Safety Temperature Limit Control (STLCY) machine, which detects and alarms an overtemperature situation in either chamber. VIP 70 N is designed with automated execution capabilities that incorporate a resistive logic control tool. This ensures rapid pre-heating through accurate control of product flow at the conveyor inlet and the automated conveyor exit. It also includes a belt-tracking asset that ensures accurate control and consistent product throughput. In summary, VIP-70N is a versatile reflow oven designed for efficient and consistent soldering of modern SMT electronics. It features a powerful burner model and advanced temperature profile control capabilities that provide a consistently high-quality solder joint. The oven also has a safe and reliable control equipment that eliminates any risk of overheating. The precise temperature profile library and automated execution capabilities ensure efficiency and accuracy throughout the reflow process.

There are no reviews yet