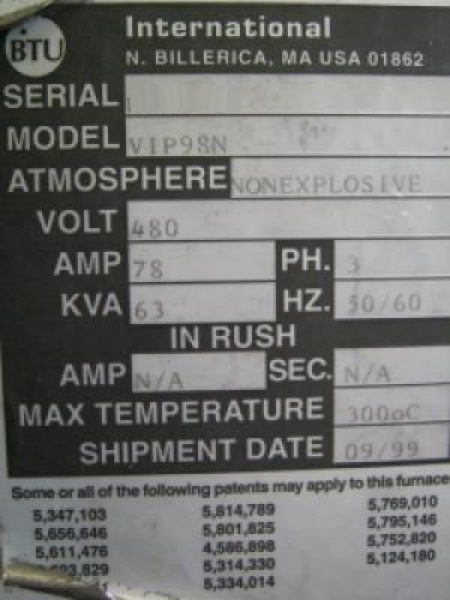

Used BTU VIP-98N #189366 for sale

URL successfully copied!

Tap to zoom

ID: 189366

Vintage: 1999

Convection reflow oven

True Chilled Refrigerated Cooling Section

(7) top and (7) bottom zones

98" heated length

22" wide mesh belt

Edge rail conveyor

Left to right flow

1999 vintage.

BTU VIP-98N is a high-temperature reflow oven that uses IR (Infrared) heating to reflow solder paste on circuit boards. The oven's low thermal mass design is capable of heating up to 600°C in under 8 minutes, making it one of the fastest reflow ovens available. The smooth heaters are housed in an all-welded stainless steel chamber with a solid top, and the cooling chamber is a UL listed forced air blower. The oven is able to accurately monitor and control the entire process through a single integral temperature controller. The controller uses advanced PID algorithms to accurately and quickly compensate for thermal losses as well as external temperature variations. The controller is also equipped with a host of safety features including self-test, process lockout, and multiple alarms. The oven has an impressive user-friendly interface, including 12-inch colour touch screen and a USB port to program setpoints independently. It also has temperature profiling software and user-friendly manual automation to increaestyle the process. A temperature recorder can be added to utilize a real-time view of temperate profiles for a variety of solders and assemblies. Advanced Ethernet support is also available to enable the oven to be integrated into production programs. VIP-98N is able to accommodate a variety of board sizes and components due to the 21-inch internal width conveyor and 15-inch heated conveyor, allowing for reticle size trays. The oven's height range is 4-7 inches and the maximum component height is 3.5 inches. The belt speed can adjust from 30 cm/min to 180 cm/min, giving operators the flexibility to process different types of PCB assemblies. BTU VIP-98N oven is the most advanced and reliable reflow oven that provides efficient, repeatable, and cost-effective results. Its reliable performance with high-level accuracy, repeatability, and features make it ideal for current and upcoming technologies. Its ability to accurately monitor, control, and optimize the entire process, further enhances its flexibility and reliability while ensuring the processing of quality and reliable products.

There are no reviews yet