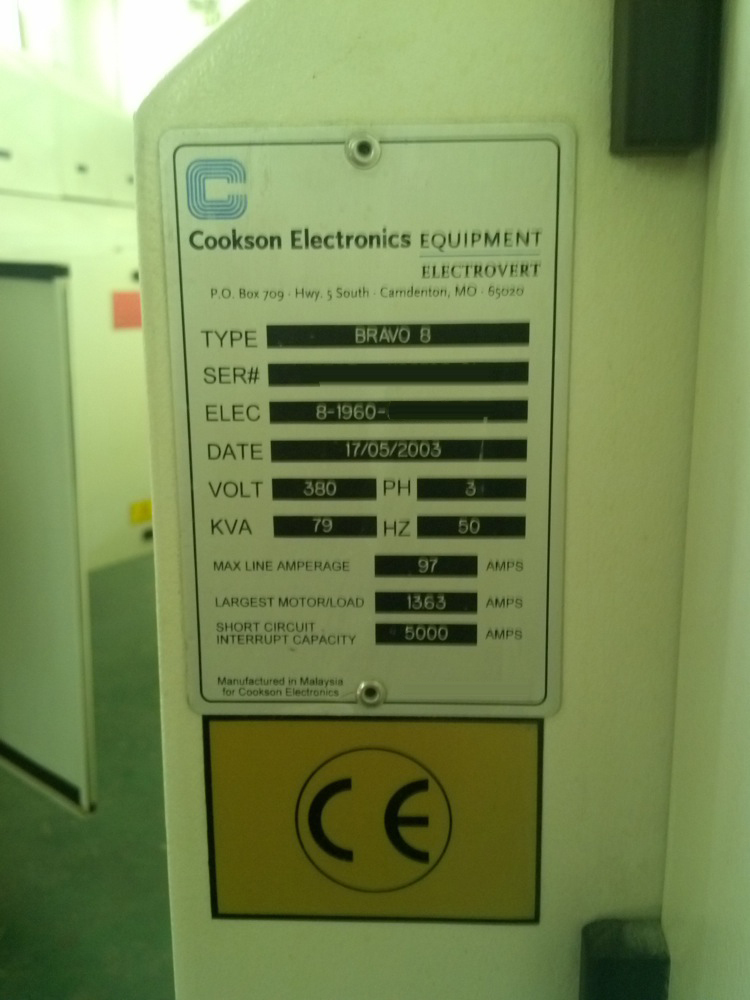

Used ELECTROVERT Bravo 8105 #9038864 for sale

URL successfully copied!

Tap to zoom

ID: 9038864

Reflow oven

Operating voltage: 380V

Current: AC

Soldering time: 5 minutes

Type: lead-free reflow soldering machines

Power Type: 40KW

Maximum effective size: 5000mm

Hot plate

Computer-controlled

2003 vintage.

ELECTROVERT Bravo 8105 reflow oven by ELECTROVERT utilizes advanced technology to provide a reliable way of soldering surface-mount components onto printed circuit boards. It is an economical, user-friendly, and highly efficient medium-sized reflow oven capable of supplying advanced zone temperature control, preheat temperature profiling, and reflow atmosphere control. Bravo 8105 reflow oven utilizes a dual-beam non-contact infrared heating equipment, which evenly supplies heat to the PCBs with precise temperature control. The dual-beam infrared design is made up of two infrared heating systems—Top Heat and Bottom Heat. The Top Heat system is used for Higher Temperature Air Profiling (HTAP) and reduces the amount of energy used compared to competitor's models. The Bottom Heat unit, better known as Infra Preheat, utilizes the dual-beam infrared heaters to preheat the PCBs before reflow. The Bottom Heat machine also keeps the PCBs at a consistent temperature throughout the entire reflow process. ELECTROVERT Bravo 8105 reflow oven is equipped with an advanced air filtration tool, which helps minimize temperature fluctuations due to air pressure. It also helps keep the air within the oven clean and impurity-free, which helps maintain the highest quality results. The air filtration asset further helps the ovens' recycle time and chamber temperature stability, resulting in higher yields and overall product quality. The entire enclosure is made of a stainless steel with fiberglass insulation to protect the interior components from heat impingement. The oven also uses a split design which enables users to open the front door of the oven without having to interrupt or restart the heating process. Bravo 8105 comes standard with a 10.4" Smart Touchscreen Control (STC) display, which allows easy and accurate programming of reflow profiles, as well as the ability to save up to 15 customized recipes. The STC also offers advanced features such as alarm history, parameter settings, diagnostics, product tracking, and a temperature graphing model. Overall, ELECTROVERT Bravo 8105 reflow oven is a reliable and efficient machine used for the soldering of delicate components onto a circuit board. It utilizes advanced technology, such as dual-beam infrared heating, an air filtration equipment, and a Smart Touchscreen display to provide superior soldering quality for high-volume production.

There are no reviews yet