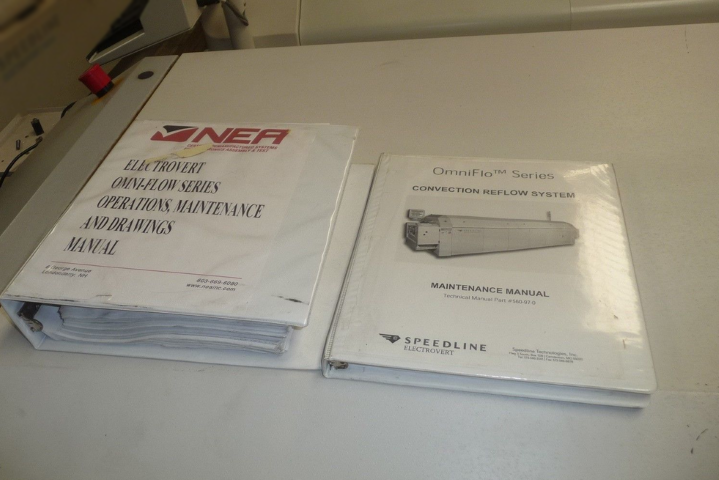

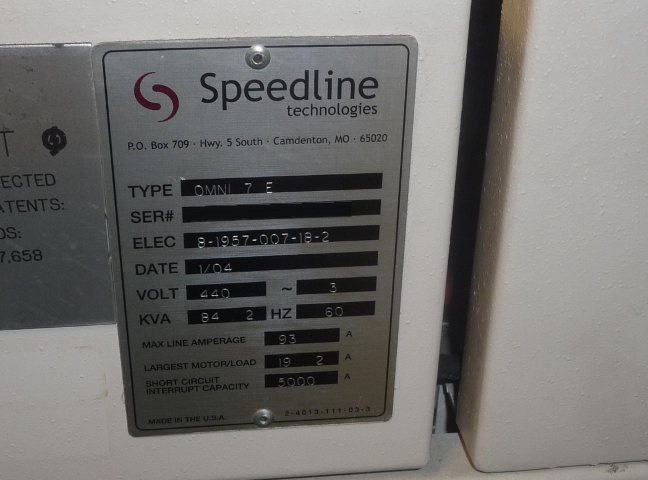

Used ELECTROVERT / SPEEDLINE OmniFlo 7E #9101914 for sale

URL successfully copied!

Tap to zoom

ID: 9101914

Vintage: 2004

Reflow oven

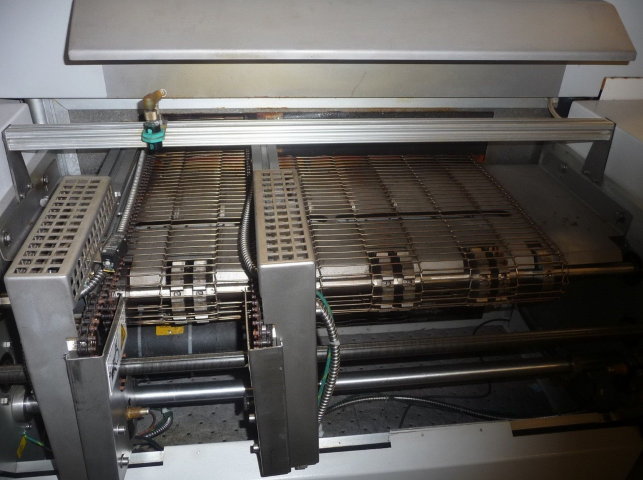

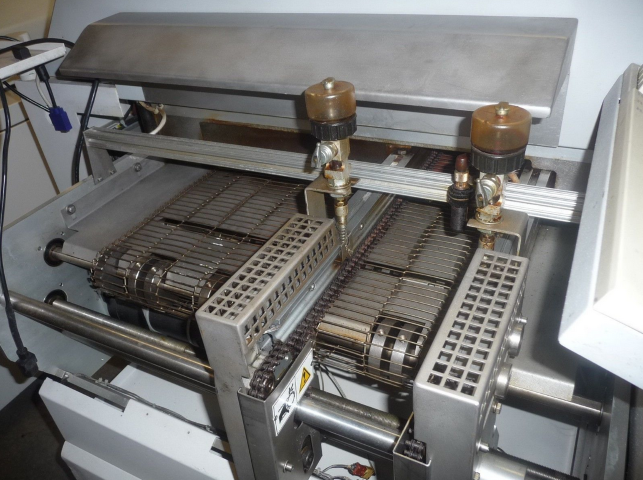

Edge Rail and Mesh Belt

Auto Chain Oilers

7 Heating Zones

3 Cooling Zones

Conveyor speed: 3 to 178 cm/min. (1 to 70 in./min.)

Process height:

Belt: 64 mm (2.5 in)

Rail: 38 mm (1.5 in) above ; 25 mm (1.0 in) below

Pin chain conveyor process width:

Minimum: 50 mm

Maximum: 508 mm (20.0 in)

Mesh belt conveyor process width:

Maximum usable: 53.3 cm (21 in)

Overall width: 55.9 cm (22 in)

Conveyor height from floor:

Belt: 81.3 cm (32 in) to 91.4 cm (36 in)

Rail: 83.8 cm (33 in) to 94 cm (37 in)

440 Volt, 3 Phase, 60 Hz

2004 Vintage.

ELECTROVERT / SPEEDLINE OmniFlo 7E is a state-of-the-art reflow oven equipment designed to provide high yield reflow soldering of electronic assemblies. This system is designed to provide production flexibility and the highest level of throughput for quick turn and continuous flow operations. The unit is comprised of several components: a chamber, a heat zone machine, an infrared collector, and proprietary software. The chamber is designed to provide the optimal environment for the deposition and curing of solder. It features a built-in particle separator, adjustable stainless steel shelves, and a roll-away door. The chamber can accommodate assemblies of varying sizes and weights, making it ideal for most production operations. Additionally, the adjustable heat zone tool is designed to provide precise temperature control and thermal uniformity throughout the chamber. This ensures a consistent solder joint throughout the entire reflow process. The infrared collector is strategically placed in the chamber to ensure homogenous temperatures across the entire board. This feature reduces thermal stresses on solder joints and helps to minimize slipping and bridging of solder beads. In addition to providing consistent temperatures, the collector also reduces cycle times significantly, increasing the overall throughput of the asset. Finally, this model is equipped with proprietary software to provide automated control of the thermal cycle. This software provides powerful visual analysis functions, such as the ability to detect solder anomalies and identify potential problems. It also features advanced programmability for adjusting temperature settings to specific customer requirements. Overall, SPEEDLINE OmniFlo 7E is a powerful and flexible reflow oven equipment capable of meeting the needs of most production operations. Its built-in heat zone system, infrared collector, and advanced software make it one of the most advanced reflow ovens on the market.

There are no reviews yet