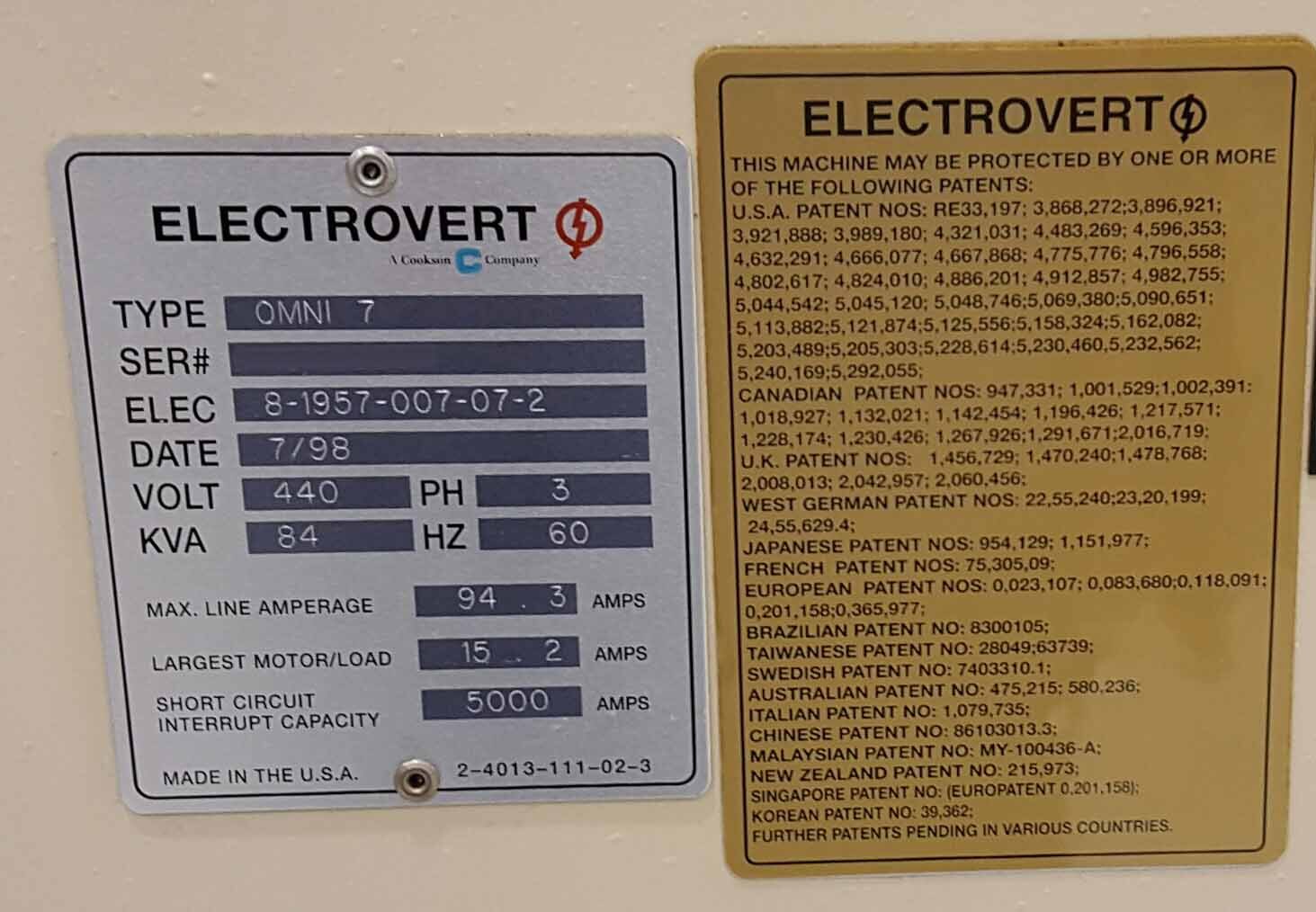

Used ELECTROVERT / SPEEDLINE OmniFlow 7 #9038715 for sale

URL successfully copied!

Tap to zoom

ID: 9038715

Vintage: 1998

Reflow oven

Directional flow: Left to right

Edge rail and mesh belt

Gas tight

Nitrogen capable

Ambient to 300° centigrade capable

Melt point (Pasty range of SAC 305 is 217°C)

(7) Upper and lower zones

Lead free capable

Chiller: No

1998 vintage.

ELECTROVERT / SPEEDLINE OmniFlow 7 is a state-of-the-art reflow oven used in the electronic printed circuit board assembly process. It features a patented simultaneous top/bottom forced-air convection equipment and advanced closed-loop process control to deliver precise and consistent soldering results. The oven is equipped with a variety of features designed to make the job easier and quicker. SPEEDLINE OmniFlow 7 features a 12-zone heating chamber and digital conveyance system, providing reliable temperature control throughout the entire process. ELECTROVERT OmniFlow 7 also includes an adjustable solder pot, allowing you to customize the profile according to your specific requirements. The soldering pot is designed to ensure consistent results and minimize potential oxidation or over soldering of the component. OmniFlow 7's Closed Loop Unit Technology (CLT) with automated programmable logic controllers (PLC) is designed to maintain all critical process variables and provide real-time feedback and control. The advanced PID control machine enables operators to easily adjust and manage the oven's temperature profile. The oven is also equipped with a fully-enclosed flux tool with digital flow regulation for an optimal and clean soldering process. ELECTROVERT / SPEEDLINE OmniFlow 7 utilizes advanced proportional-integral-derivative (PID) technology to ensure consistent, accurate and repeatable results. The PID controller helps to ensure that all of the temperatures remain consistent throughout the reflow process, resulting in improved solder joint quality with reduced thermal stress and component failures. SPEEDLINE OmniFlow 7 also features an innovative patent-pending heating asset to provide enhanced control and thermal accuracy. With this model, the oven ensures uniform top/bottom heating of board, dissipating heat faster than the traditional top/bottom heating, as well as decreasing cycle time by up to 10%. In addition, the temperature accuracy is improved by up to +/- 3°C. Finally, ELECTROVERT OmniFlow 7 features a wide range of conveyor speeds and a fully-adjustable conveyor path, allowing users to precisely control the speed and angle of the conveyor for maximum productivity. The conveyor equipment also features durable drive rollers and a stainless steel roll deck for increased longevity and reliability. In summary, OmniFlow 7 is an advanced, user-friendly and reliable reflow oven, designed to ensure accurate, consistent and repeatable results. It features a wide range of features, including a 12-zone heating chamber, digital conveyance system, adjustable solder pot and a fully-enclosed flux unit. Moreover, the oven utilizes advanced PID technology and a patented simultaneous top/bottom forced-air convection machine for improved temperature control and accuracy. Finally, the conveyor tool provides precise speed and angle control, allowing you to get the most out of the oven.

There are no reviews yet