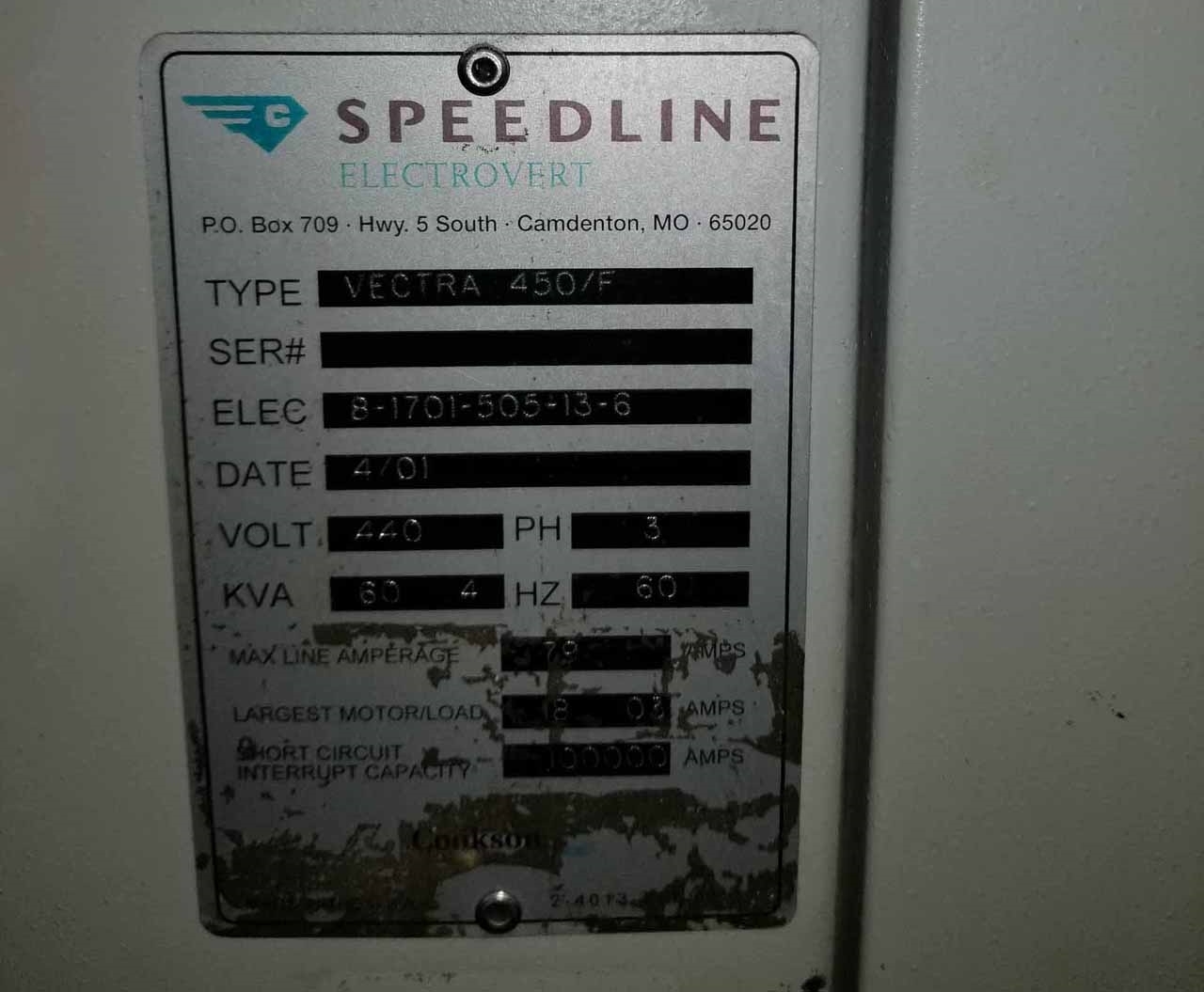

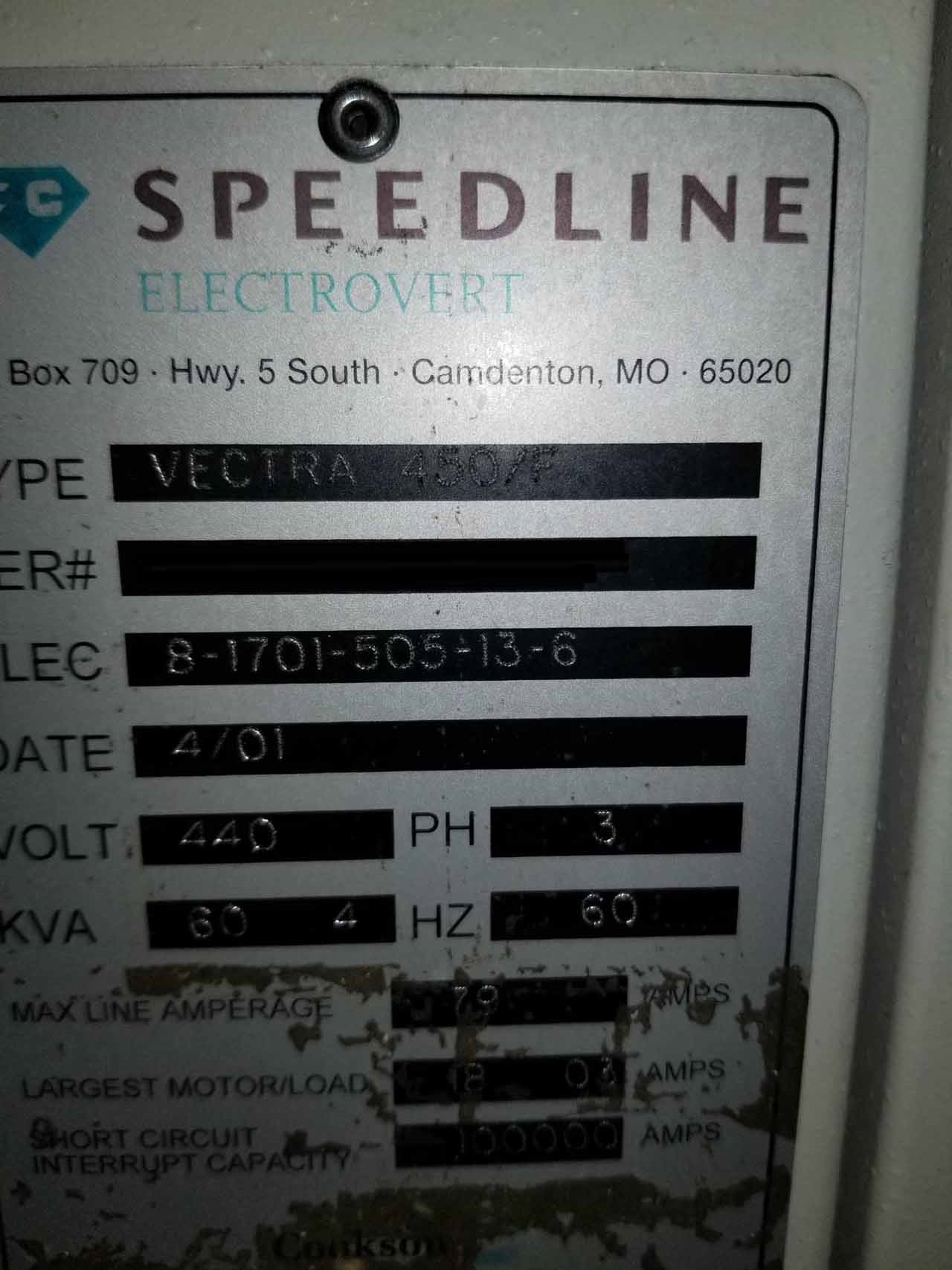

Used ELECTROVERT / SPEEDLINE Vectra 450F #9230692 for sale

URL successfully copied!

Tap to zoom

ID: 9230692

Vintage: 2001

Wave soldering machine

Ultra fill nozzle upgraded from main wave nozzle

Lead-free: SAC Alloy

No chip wave

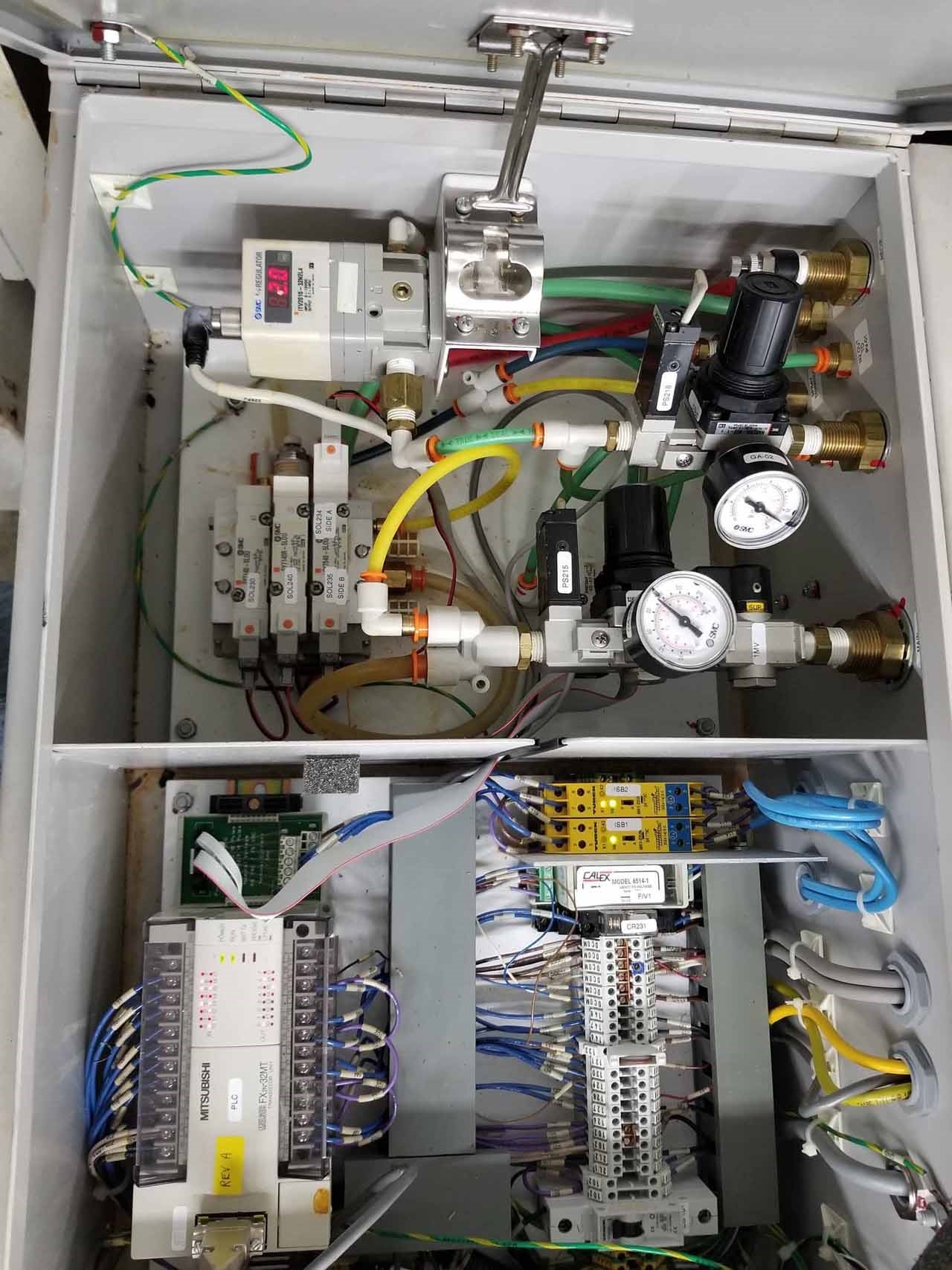

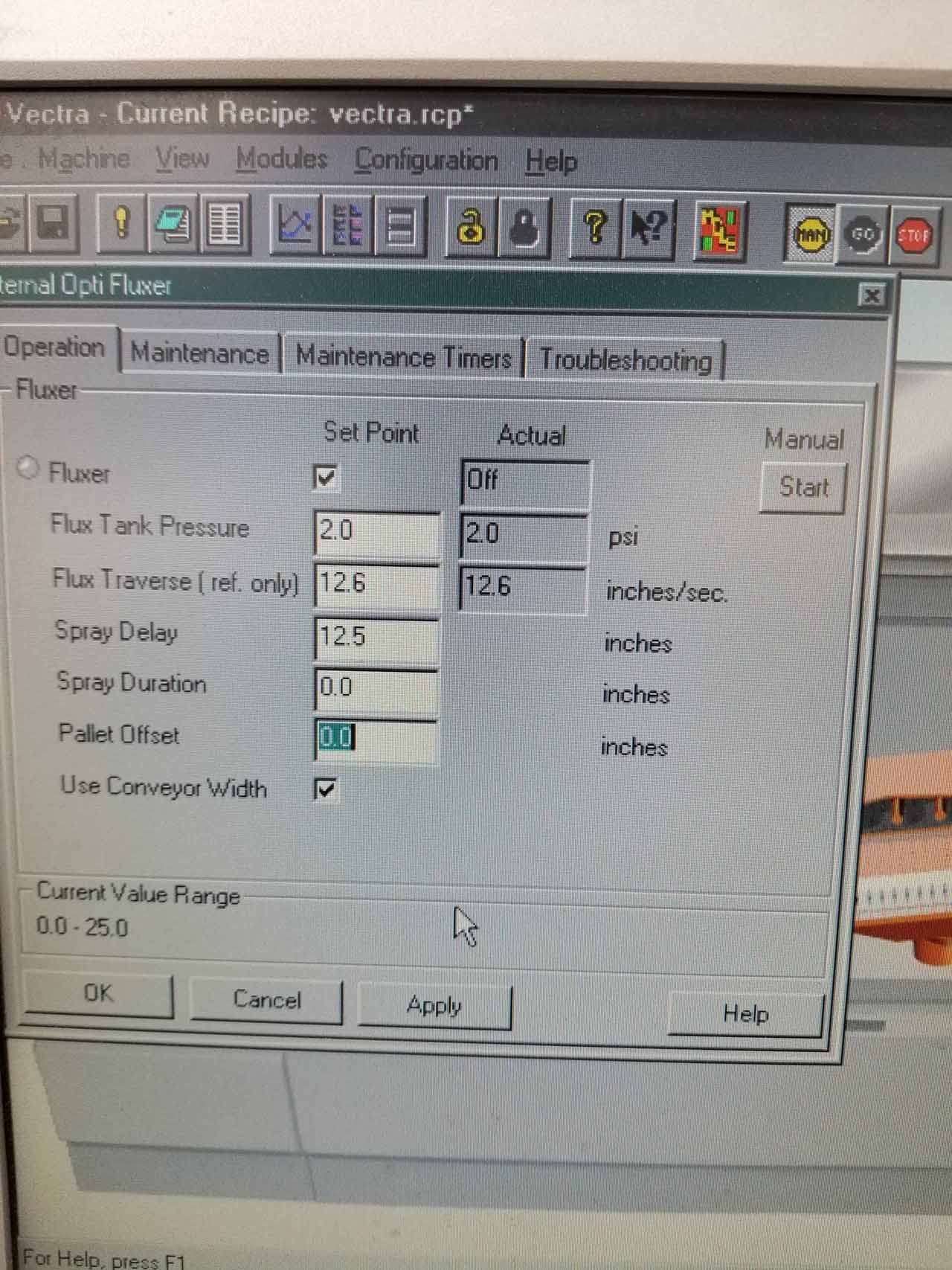

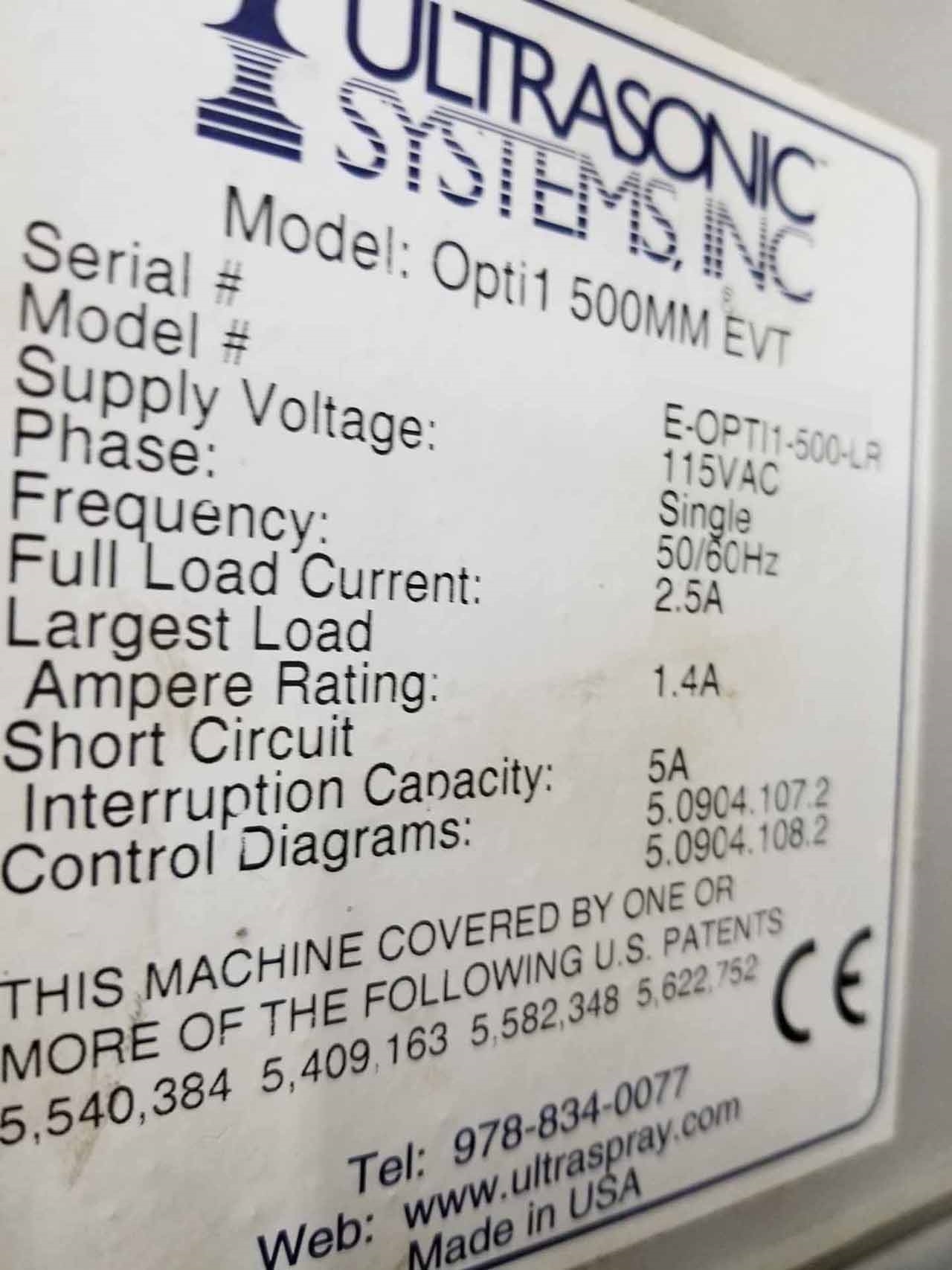

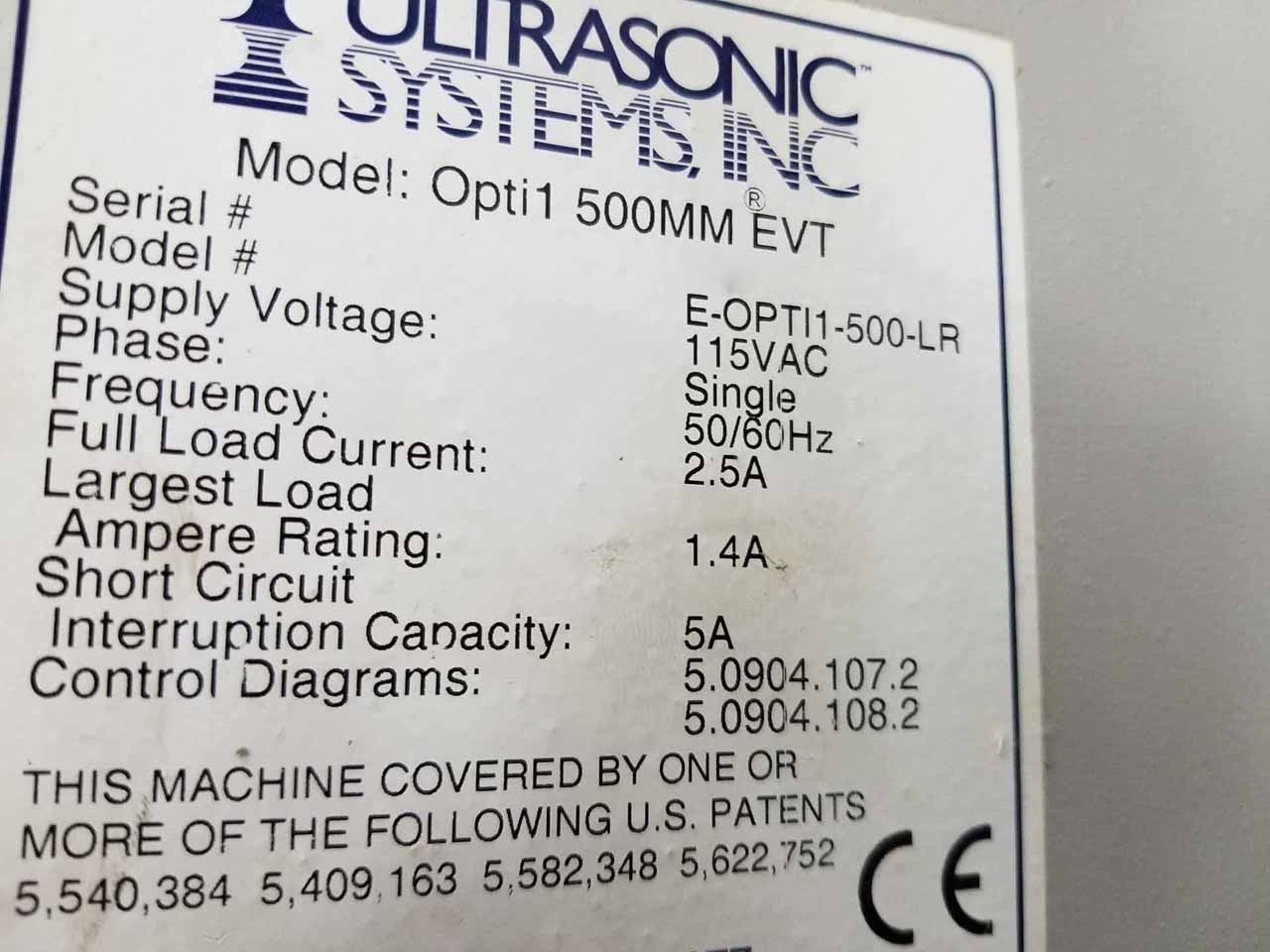

USI Fluxer: 110 VAC

Dry shop air

USI Opti flux spray fluxer: E-Opti I

Board flow: Left to right

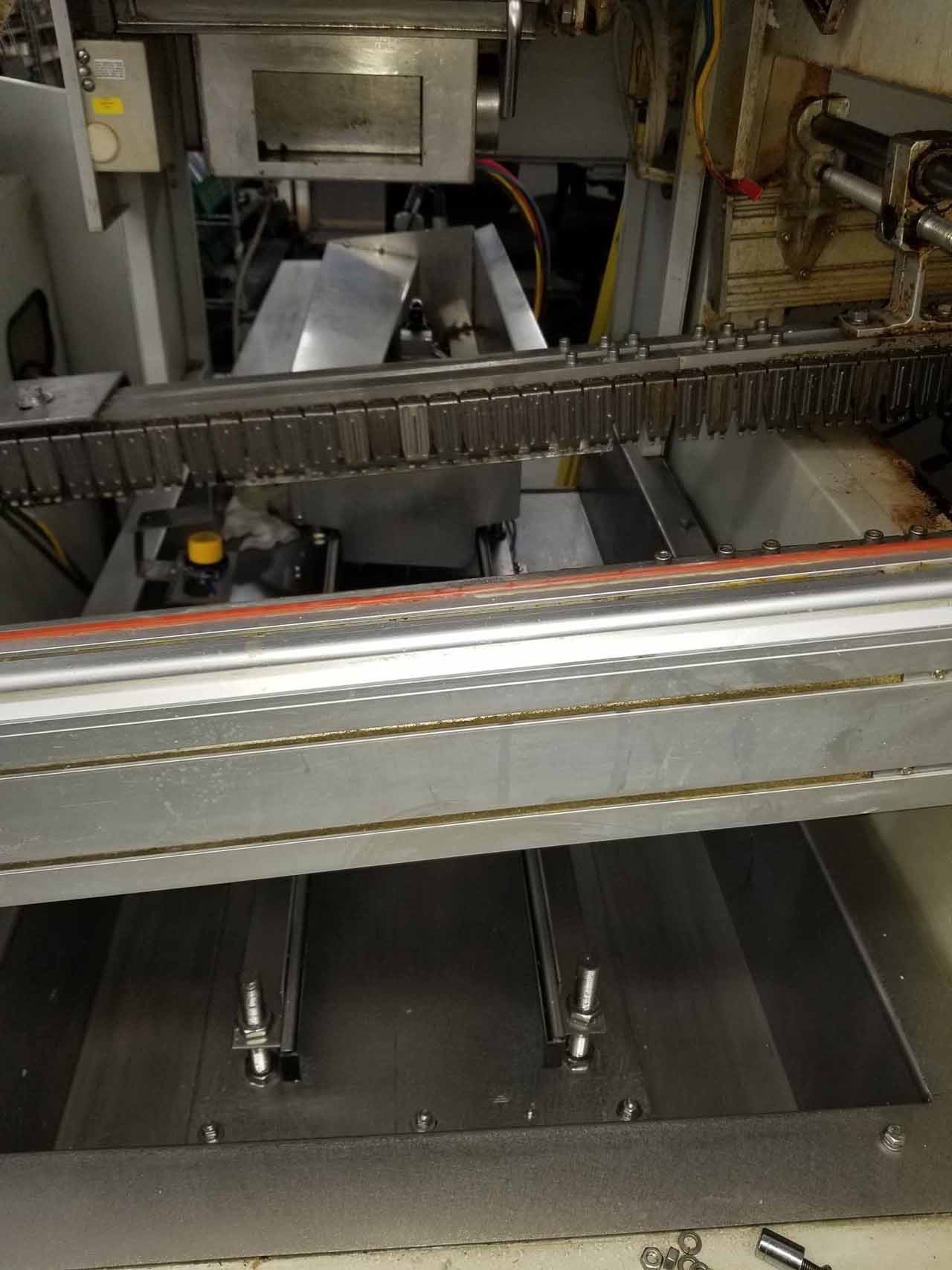

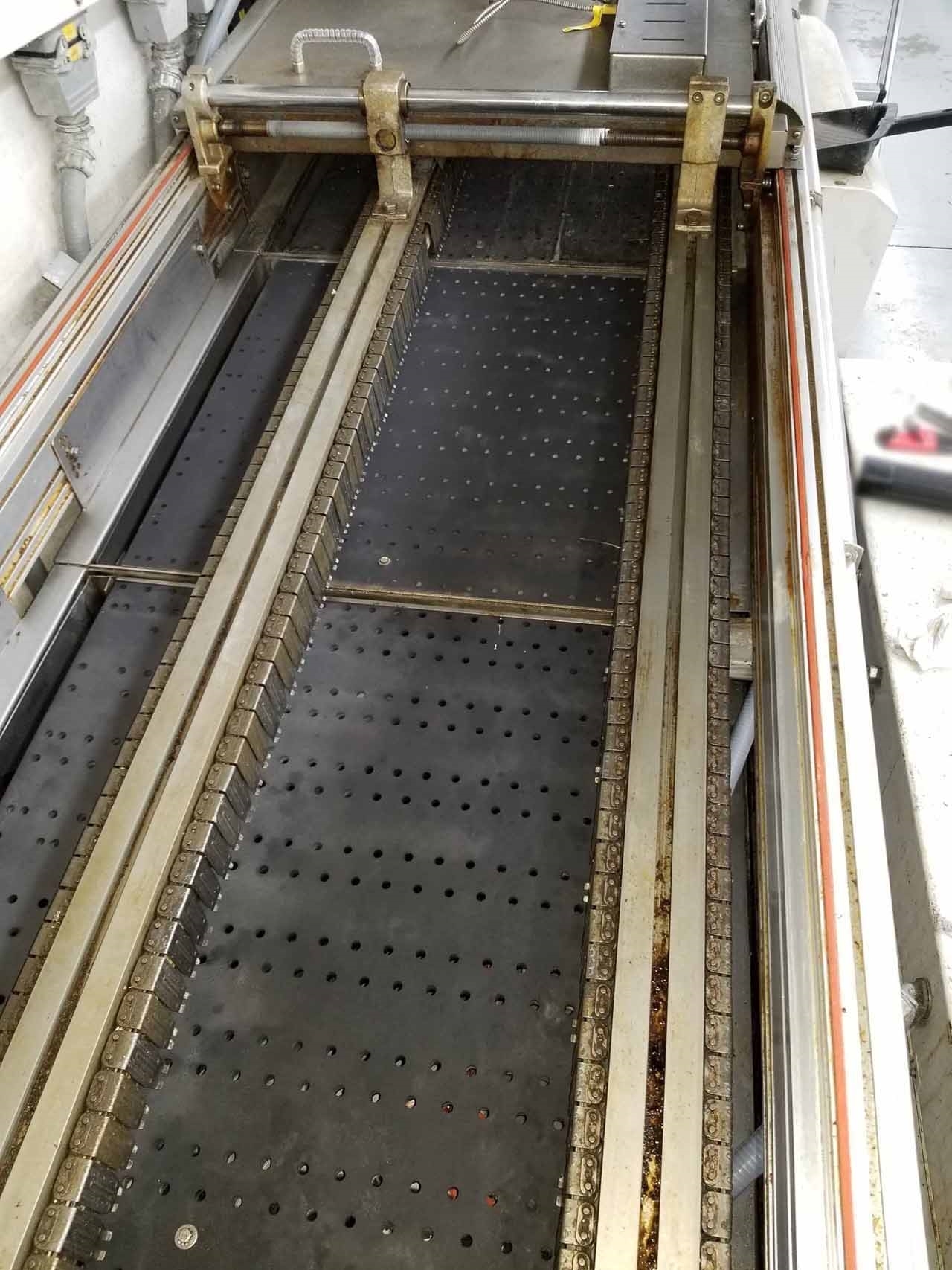

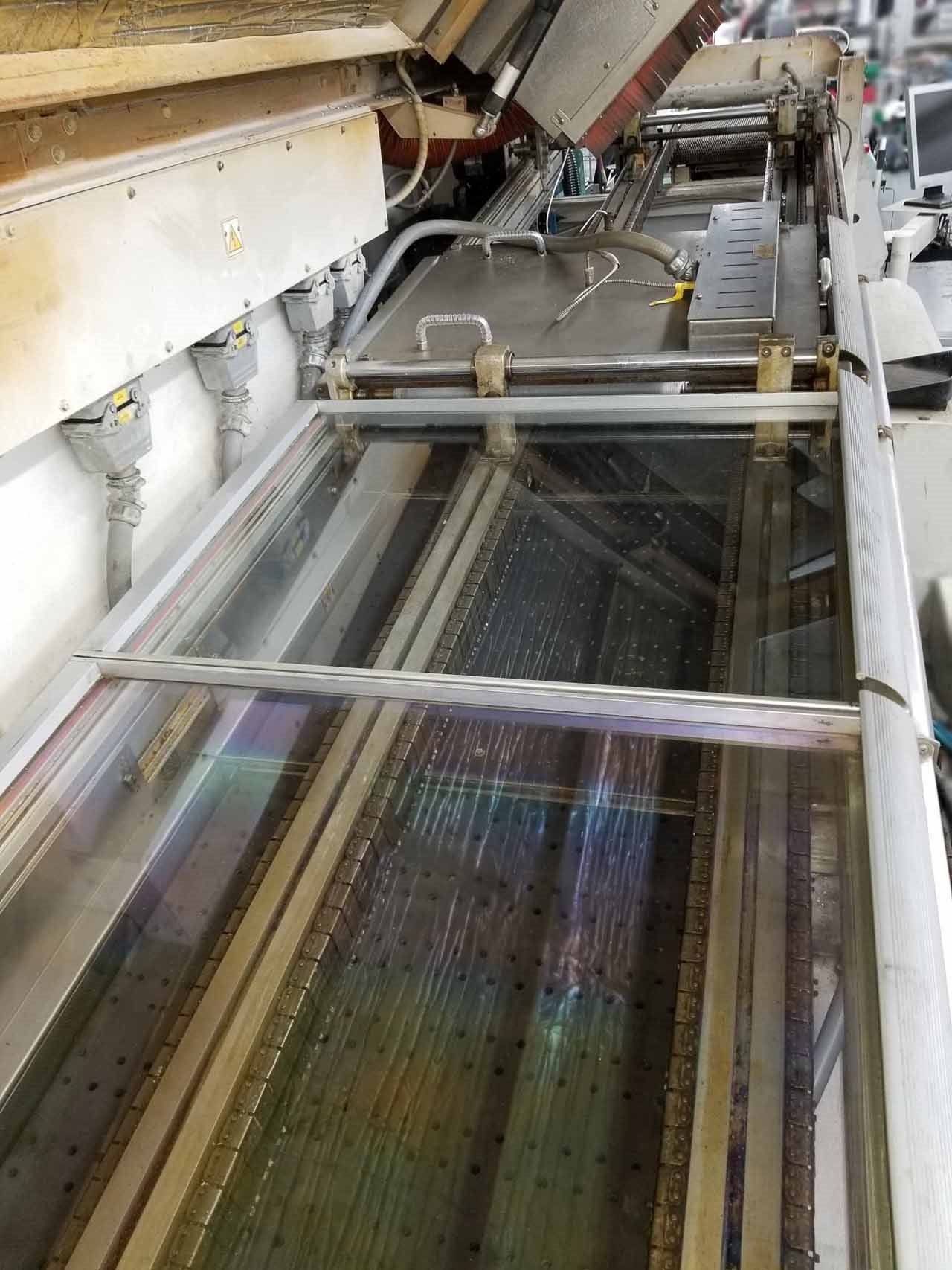

Process width: 18" Maximum

Under spray rail guards

Intermix ribbed: V and L Fingers

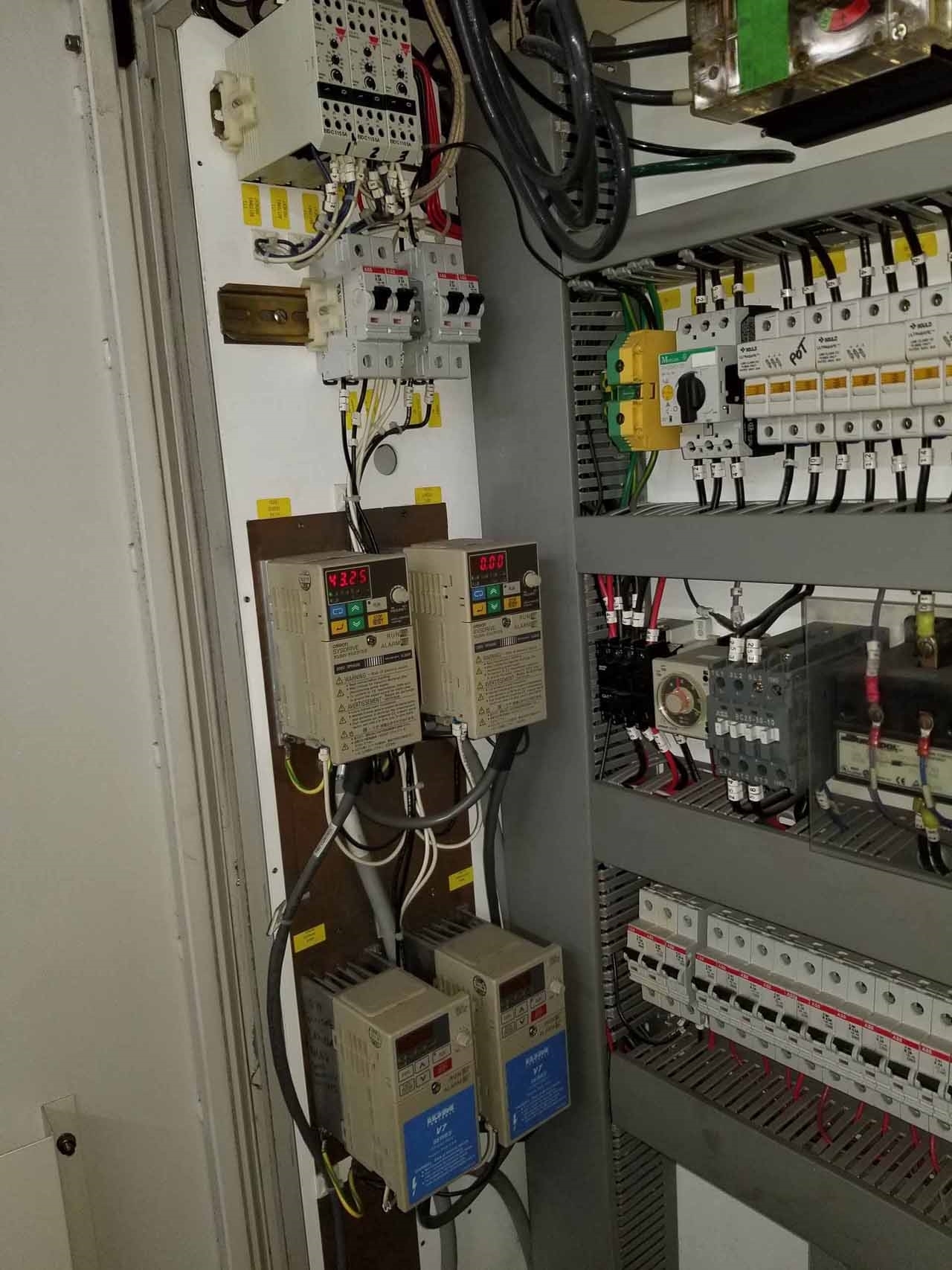

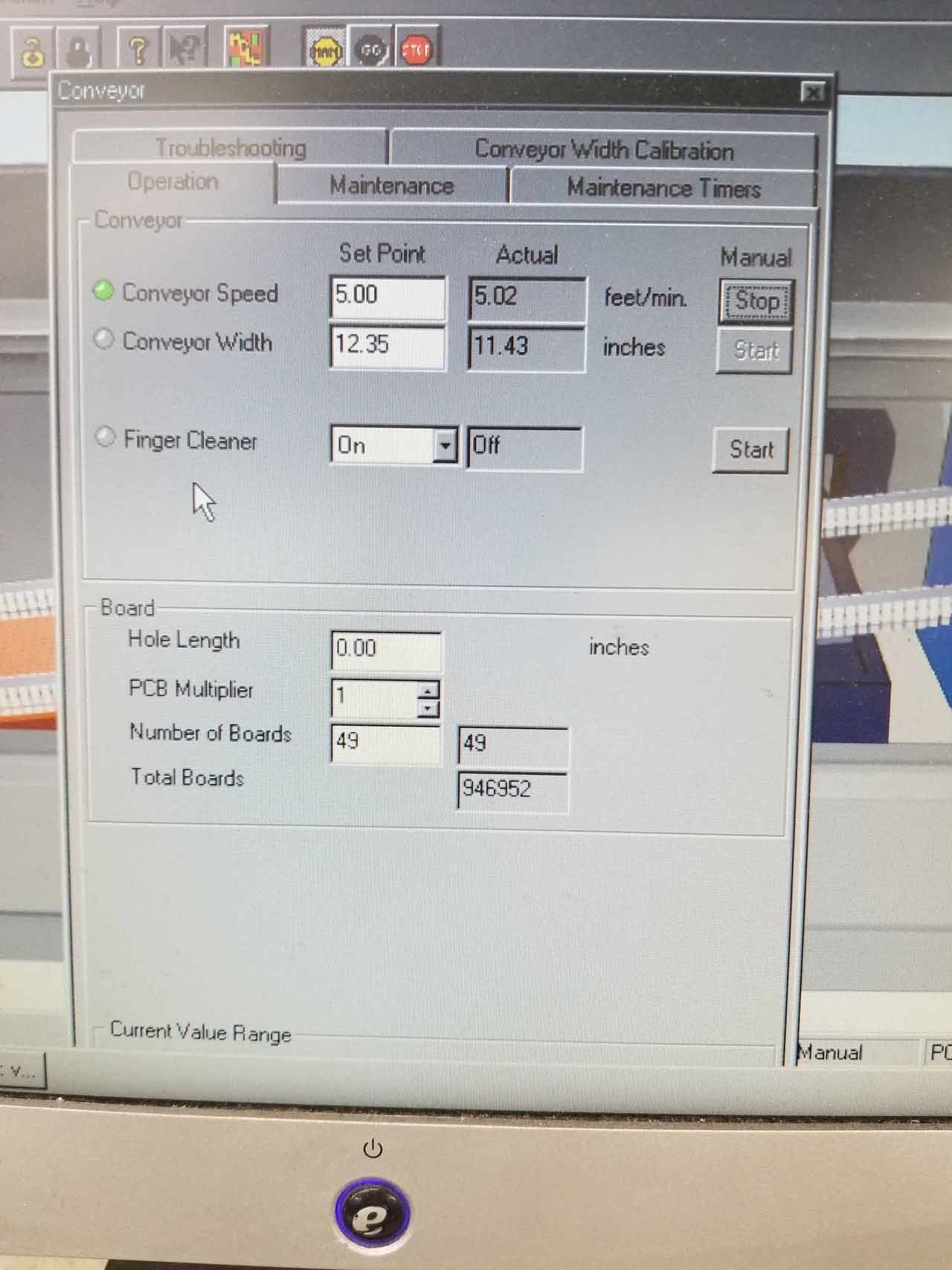

Rail width adjust: Auto and manual

Titanium solder pot liner

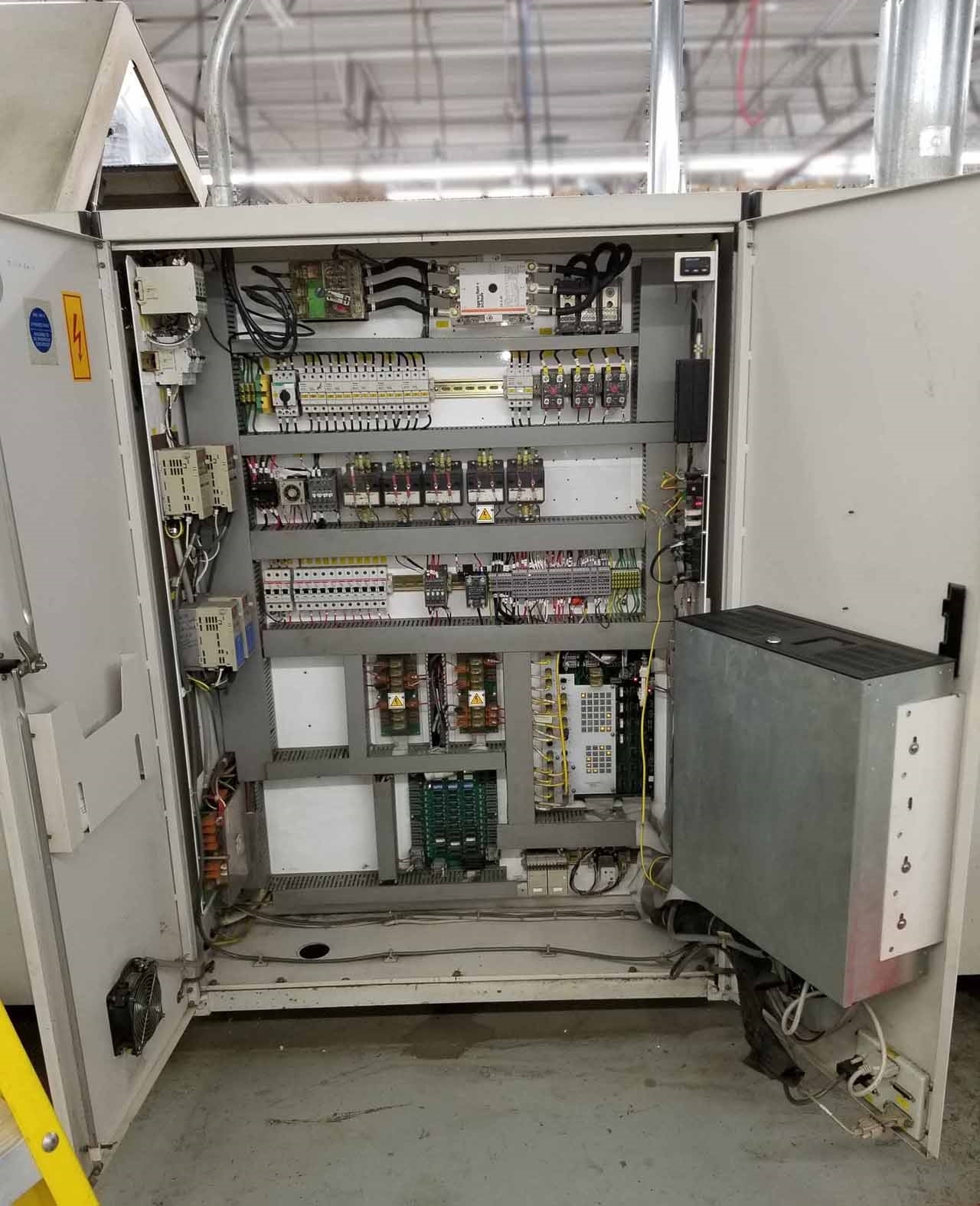

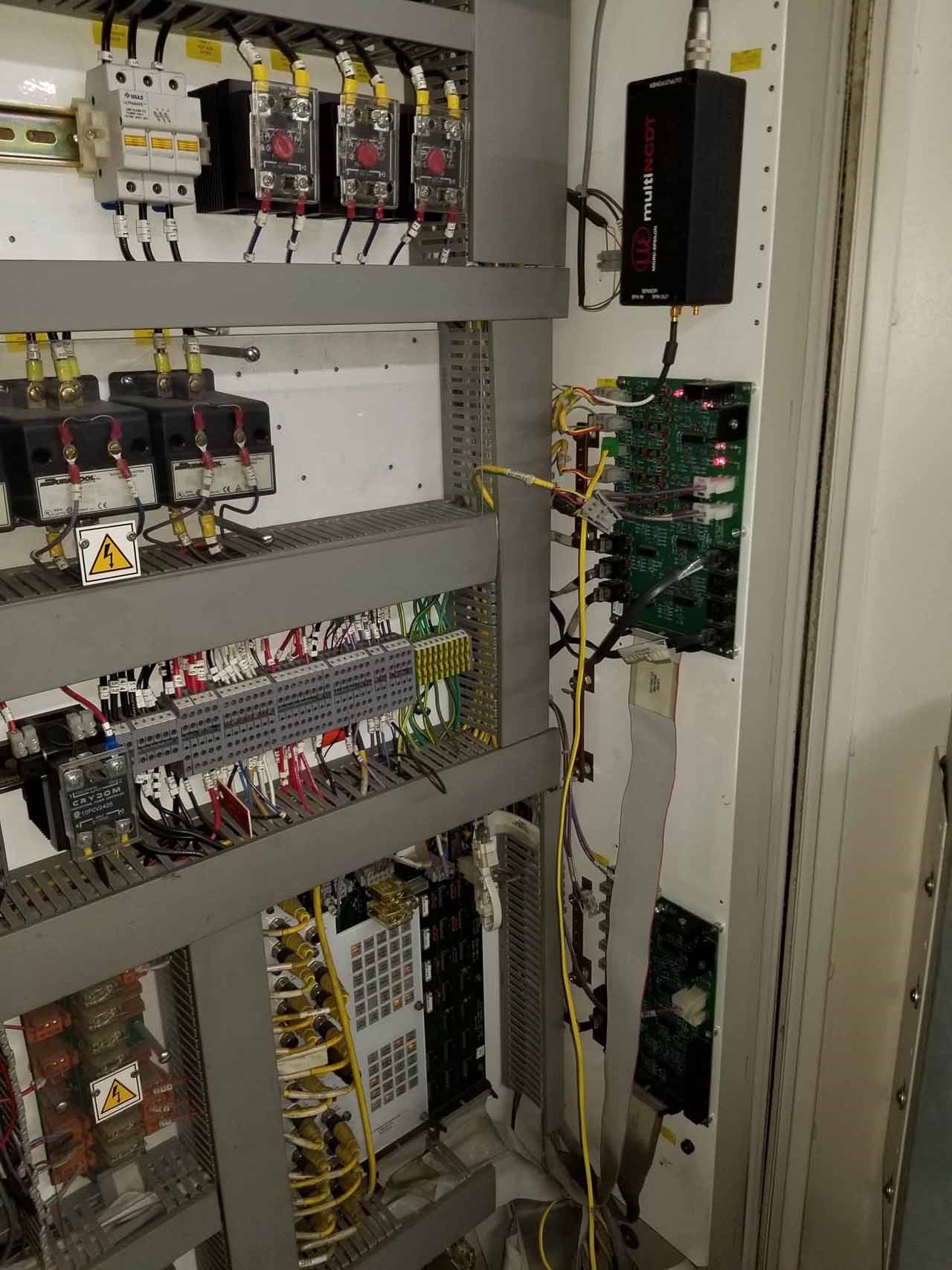

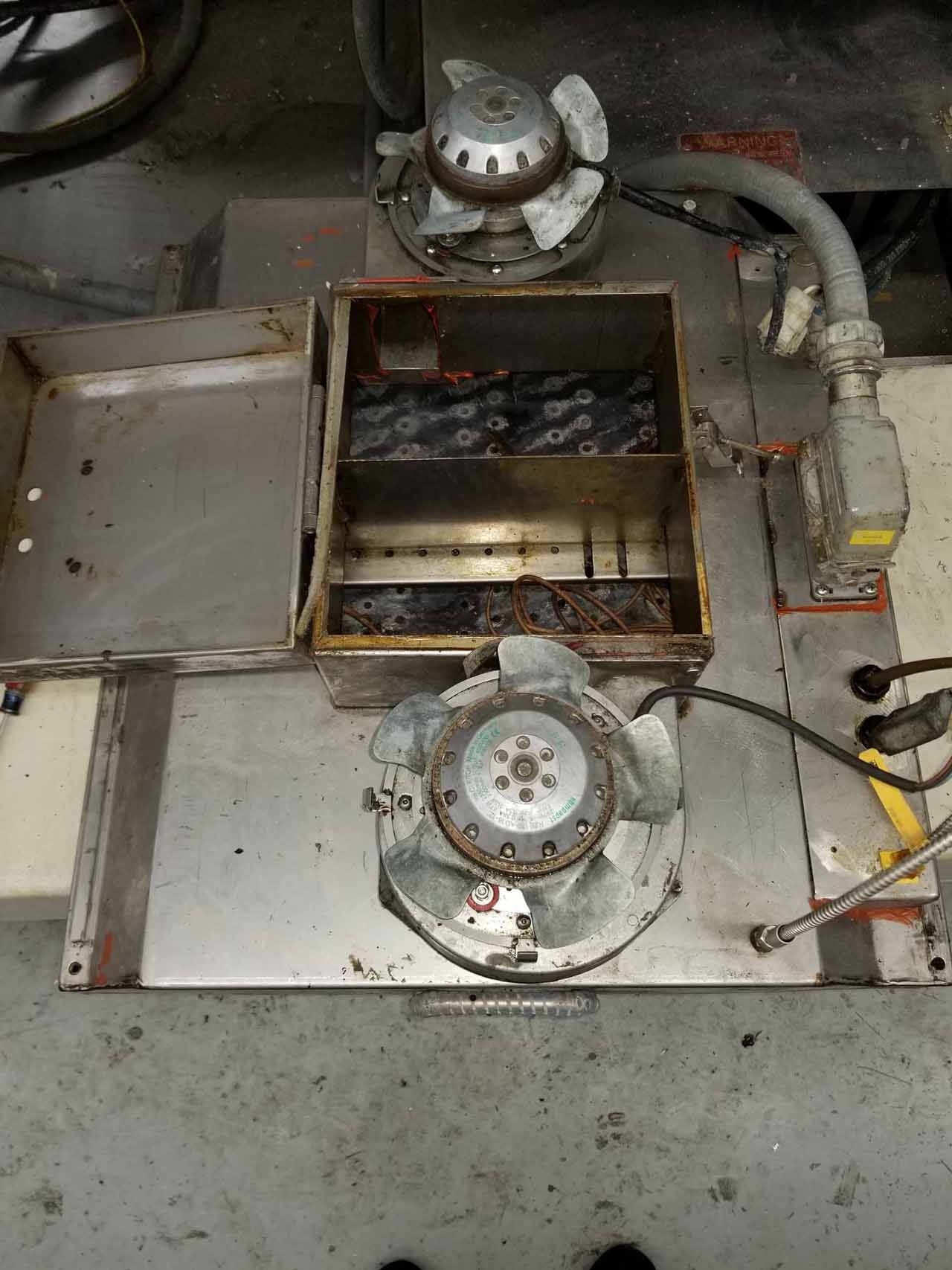

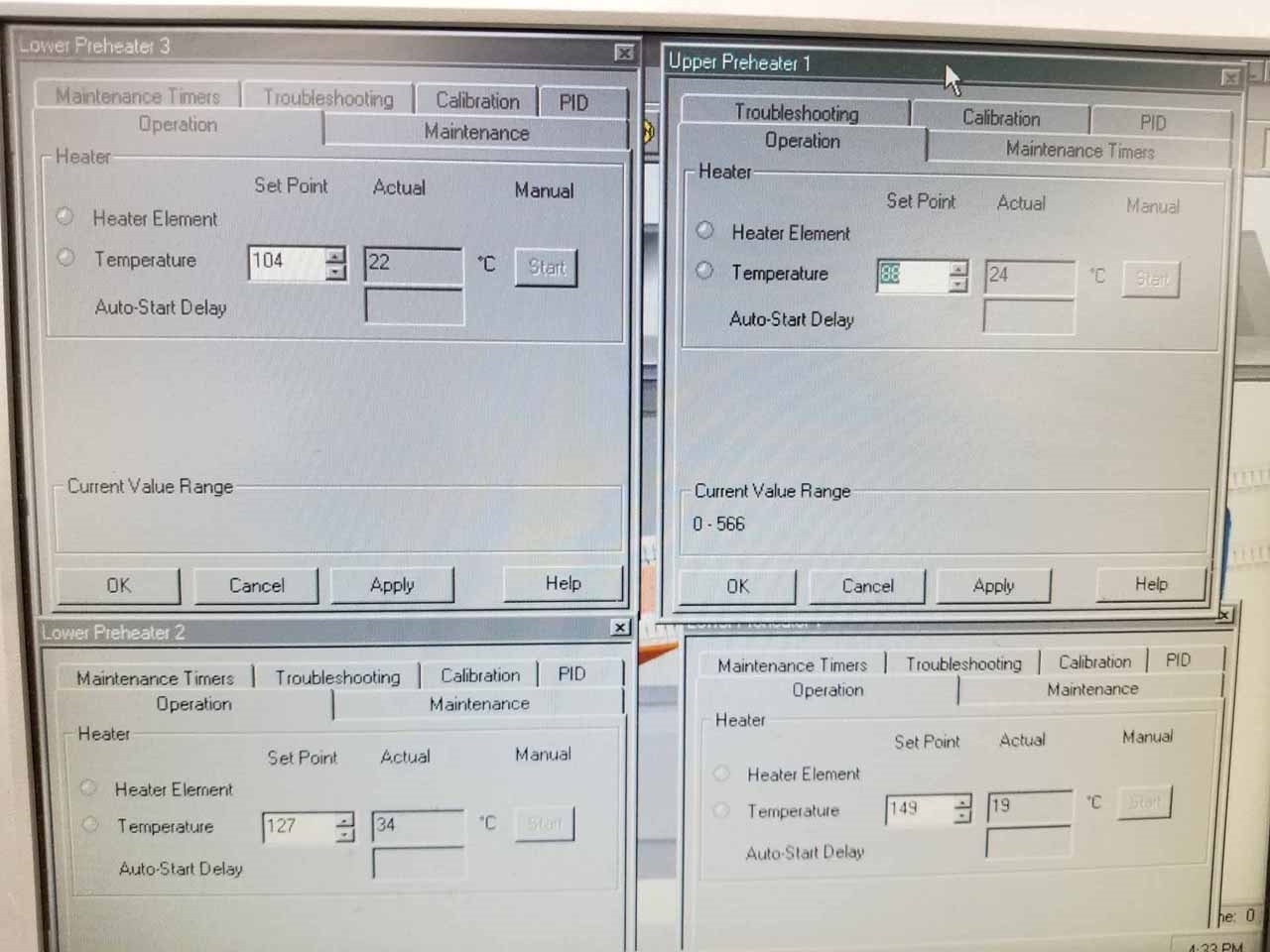

(3) Bottom convections:

Pre-heaters

Top IR pre-heater

Ultra fill main solder wave

Melonite coated

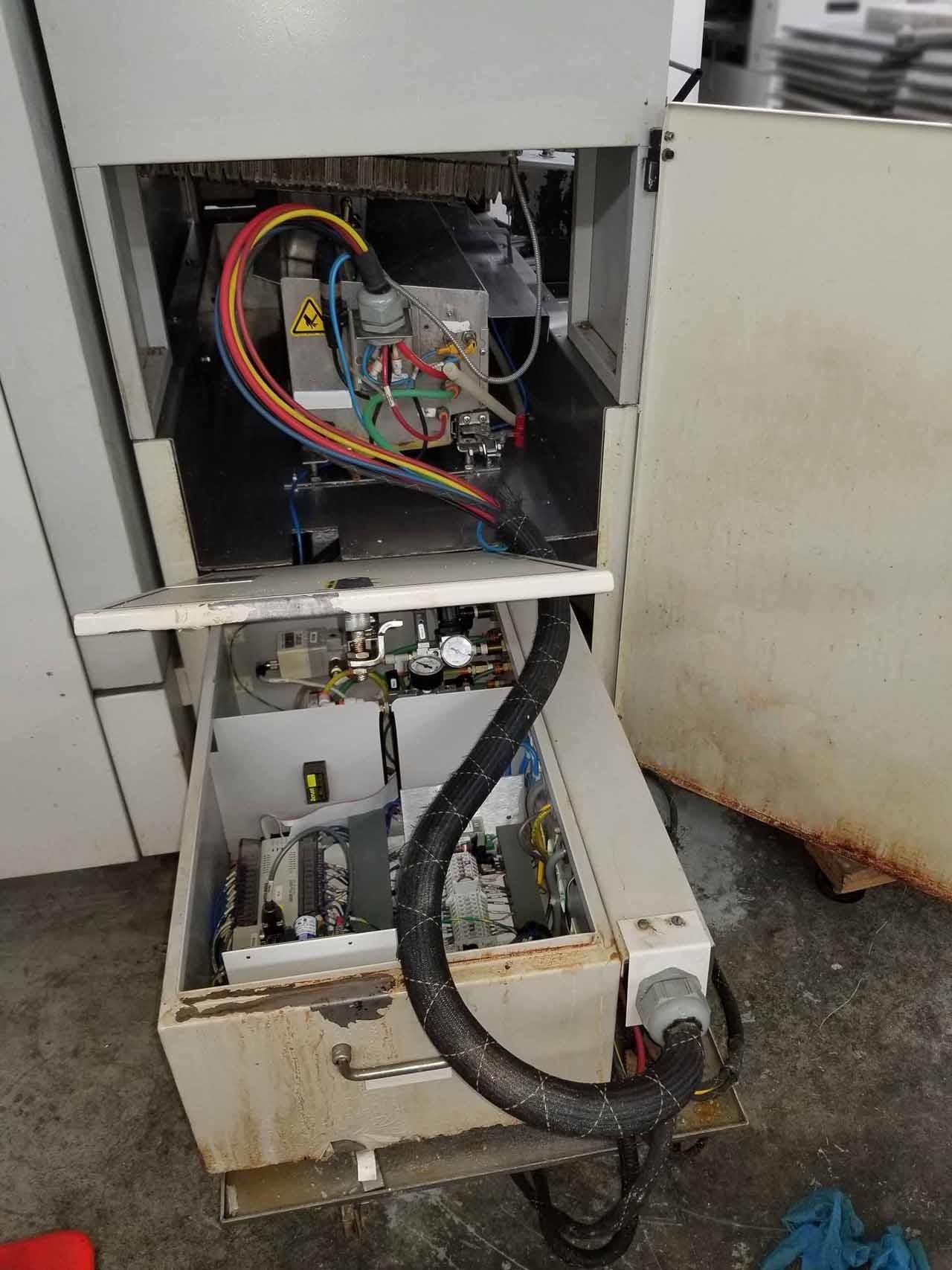

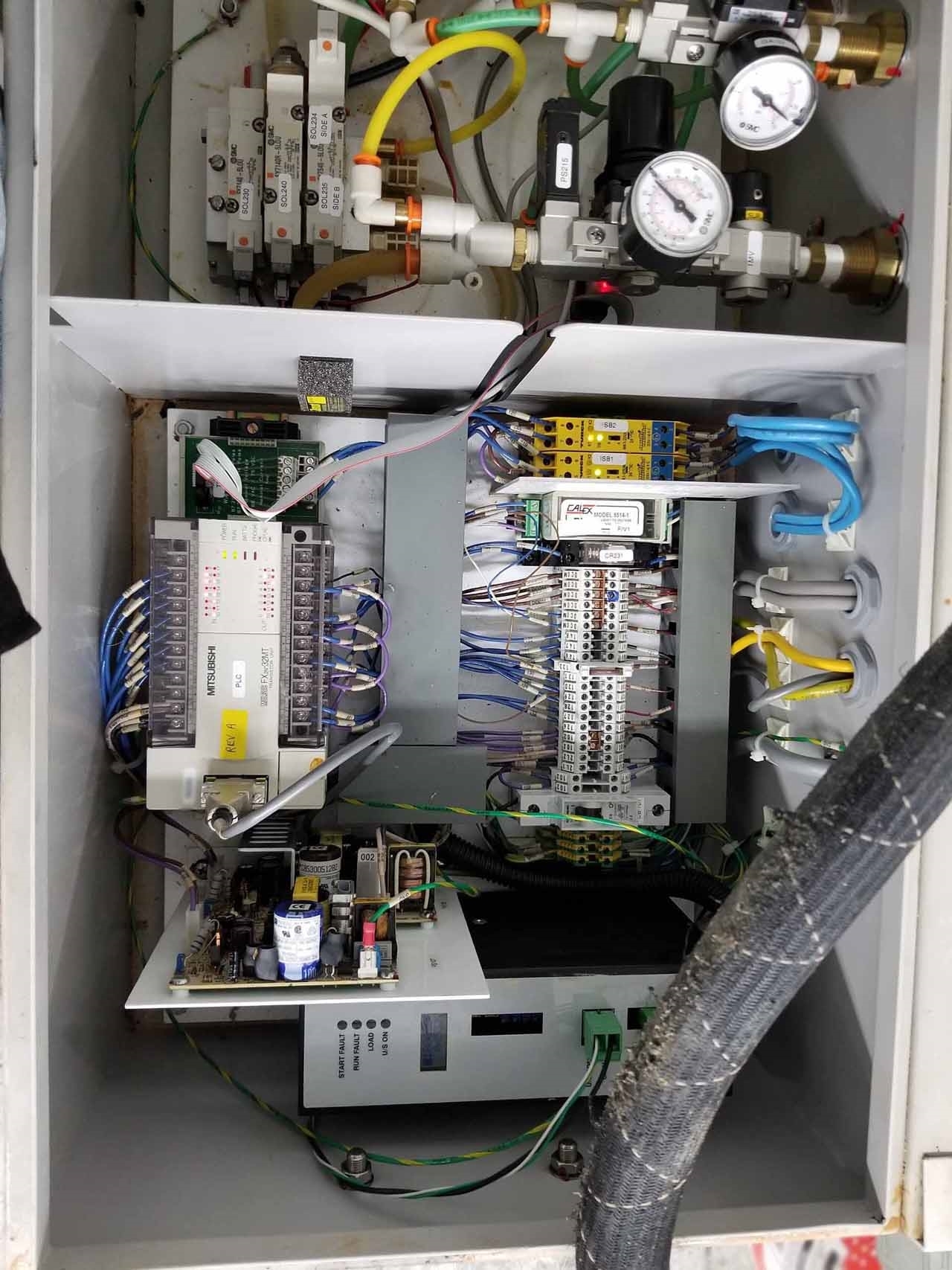

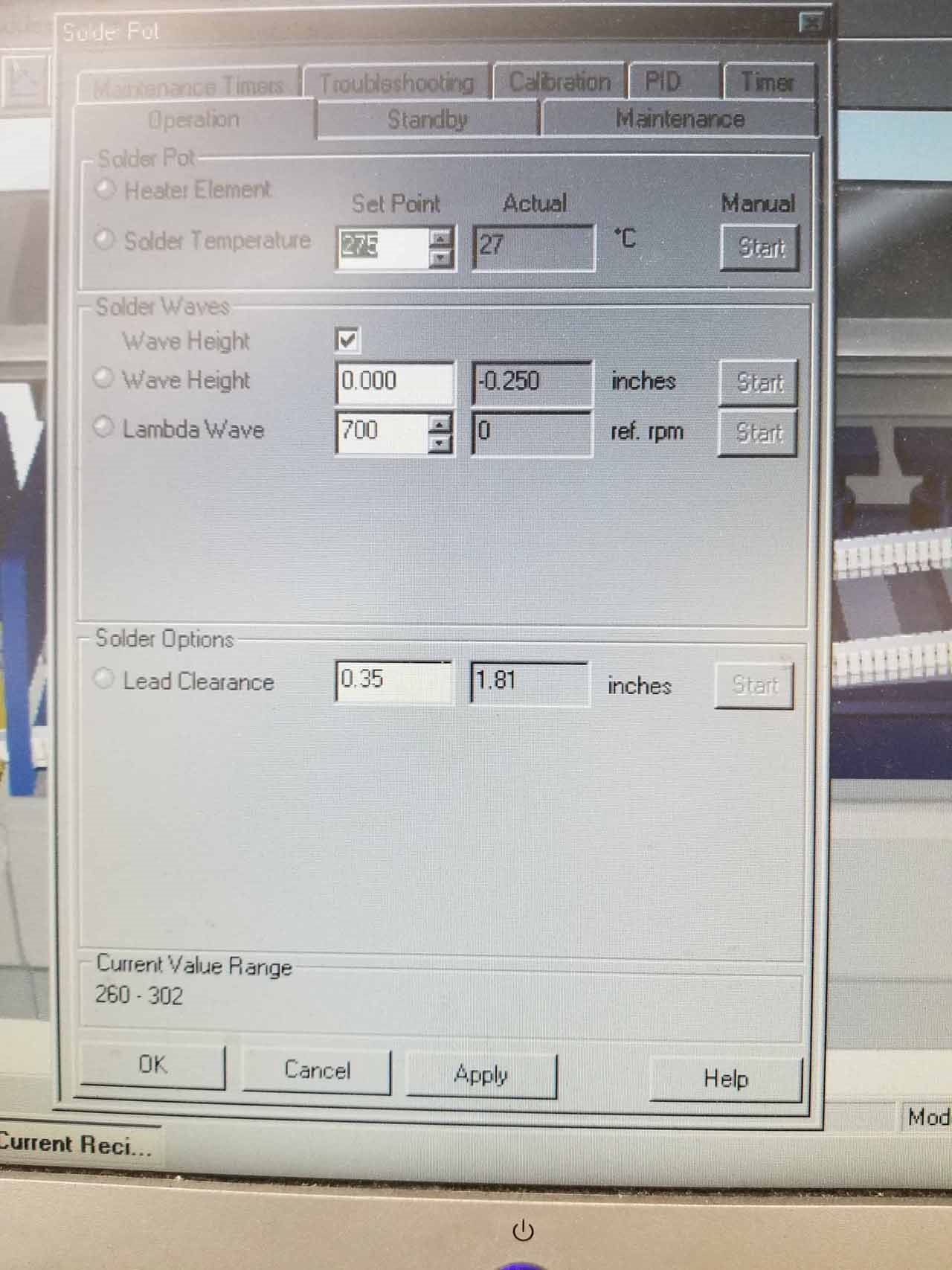

Auto solder pot:

In / Out

Up / Down

Includes:

Operation manuals

Electrical schematics

Monitor keyboard and mouse

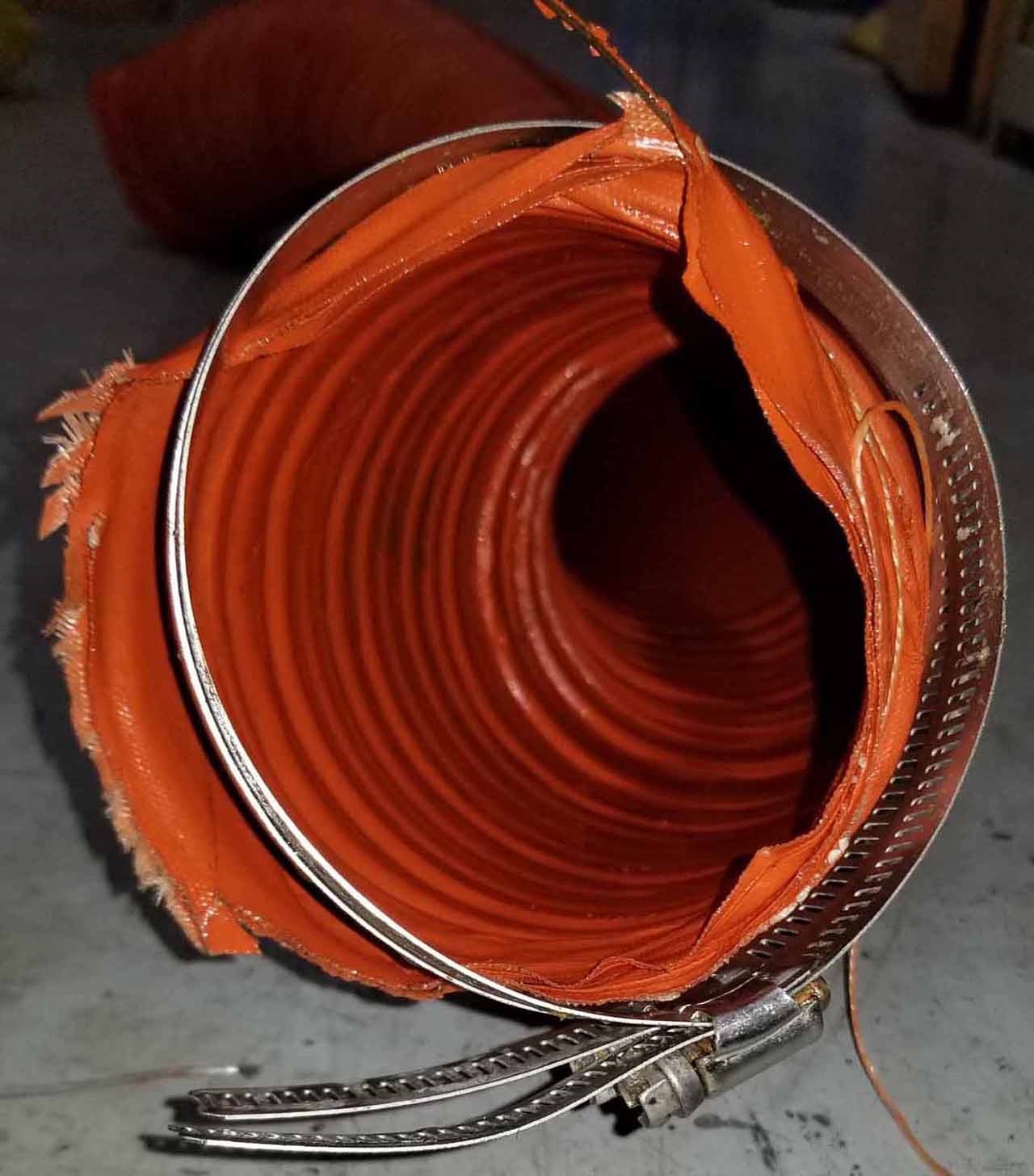

Finger cleaner repair

Power supply: 440 VAC, 3-Phase

2001 vintage.

ELECTROVERT / SPEEDLINE Vectra 450F is an advanced conveyerized reflow oven, ideally suited for small to medium sized production PCBs. It is ideal for SMT assembly processes and can handle large and complex parts with ease. The oven is built with rugged construction and high performance features that enable it to perform in production while being highly reliable and reliable. It has features such as precise temperature control, advanced air circulation patterns, reliable safety controls, and a digital display, to help ensure the quality of your products. SPEEDLINE VECTRA 450/F has a top and bottom temperature control equipment, allowing it to reach temperatures up to 450degF. It also has three heated channels and a K-type thermocouple connection for precise temperature measurement. This allows for excellent accuracy in temperature tracking and maintenance. It also features a high performance air system, which distributes air vibrations to provide uniform heat distribution and are directed in a very reliable and repeatable fashion. The oven has a user friendly all-language operation, allowing operators to easily set parameters for optimal performance. It also has a built-in automatic door safety unit which prevents users from leaving the oven door open unintentionally. This provides peace of mind, especially during busy production periods when the oven may be running in a different room. The oven also features an accurate conveyor control machine with variable speed settings, allowing the conveying of products at high speeds or at minimal speed, depending on the requirements of the operator. The oven can accommodate a wide range of PCB sizes and can handle lead-free and leaded boards with ease. It also has a corrosion resistant interior coating and a rotating array of nozzles that ensures that all the heat is evenly applied to the product. ELECTROVERT VECTRA 450 / F has diagnostics monitoring and real-time status feedback. It also comes with optional data logging including data storage, and has numerous options with regard to output configurations. This includes the ability to connect to a PC for real-time data analysis. Additionally, the oven is CE compliant, allowing for use in Europe. Overall, SPEEDLINE VECTRA 450 / F is an advanced reflow oven, ideal for medium-scale production. With its fast heating, accurate temperature control, reliable air circulation and numerous features, VECTRA 450/F is ideal for PCB assembly processes and providing exceptional quality and safety for your business.

There are no reviews yet