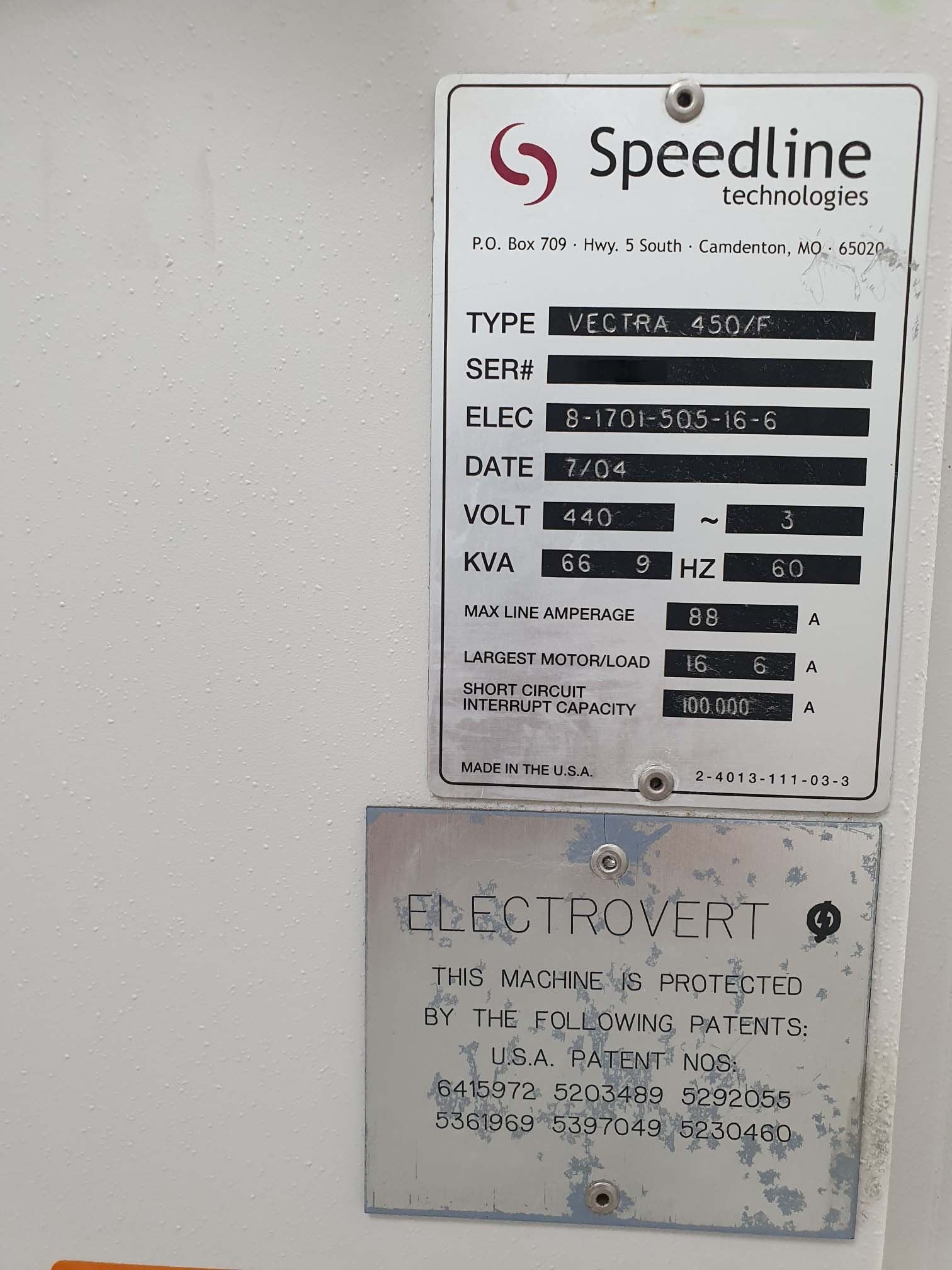

Used ELECTROVERT / SPEEDLINE Vectra 450F #9296592 for sale

URL successfully copied!

Tap to zoom

ID: 9296592

Vintage: 2004

Wave soldering machine, parts system

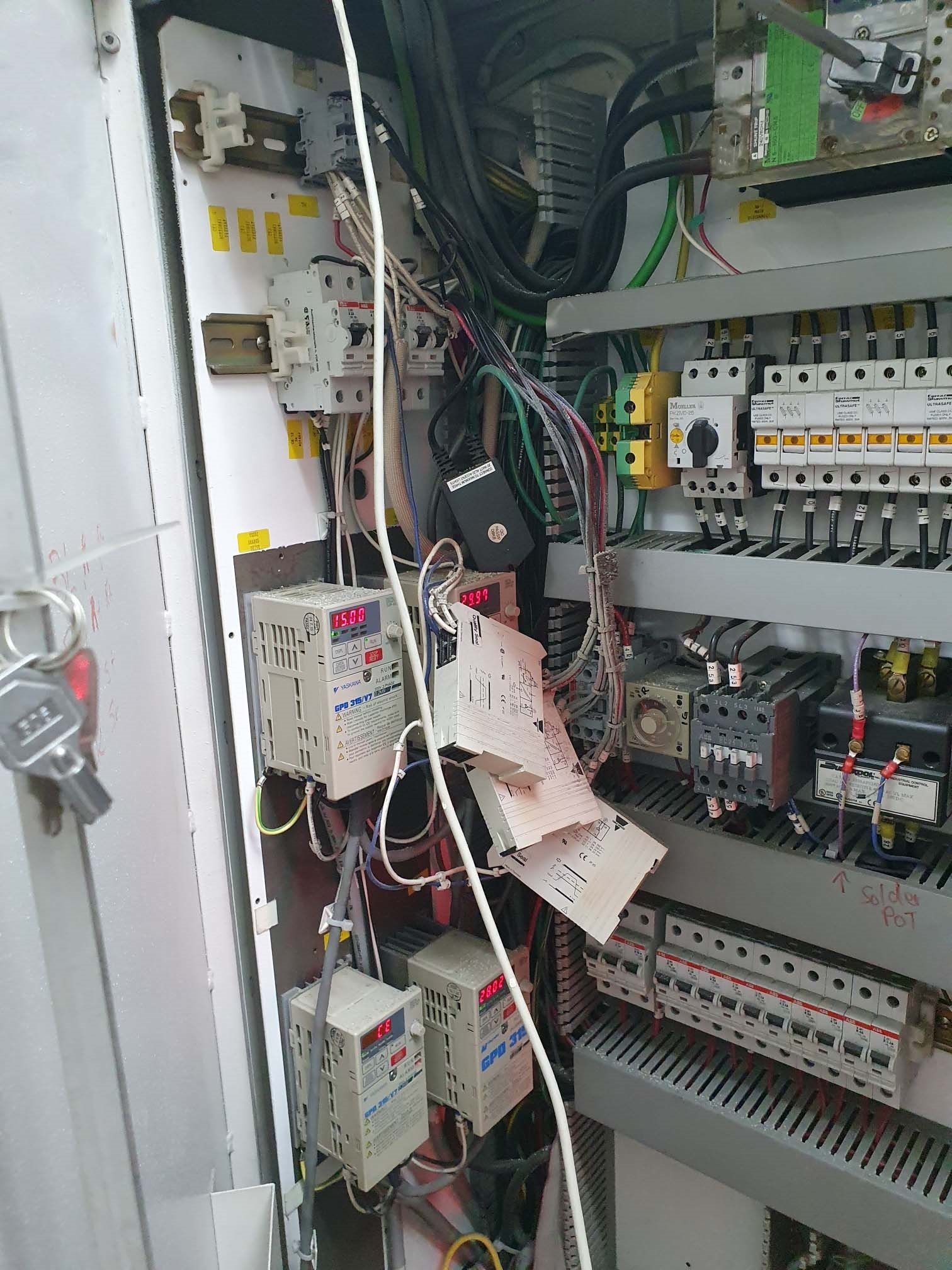

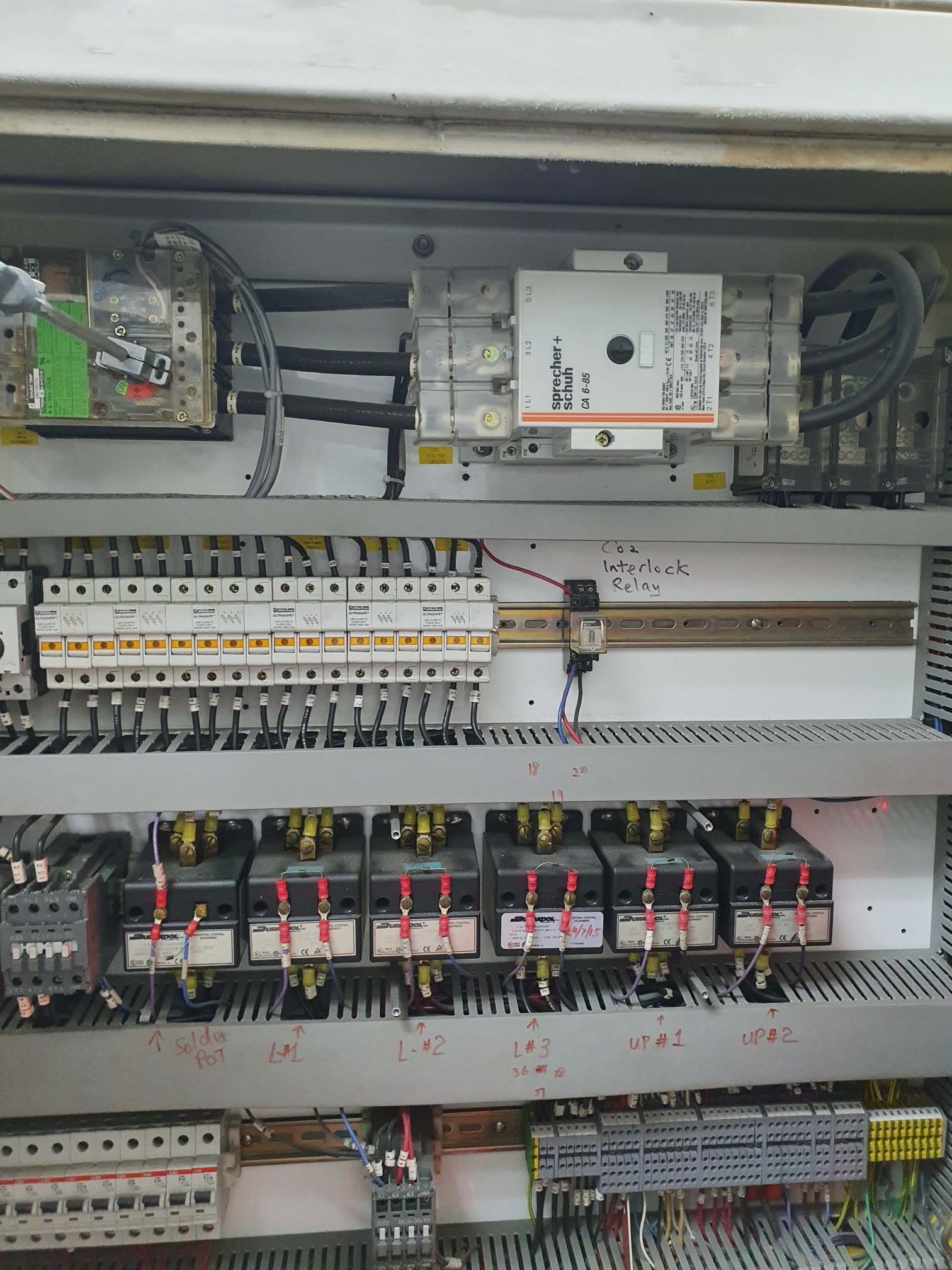

Removed parts:

(2) Pump impellers

(2) Solder pump motors

Conveyor speed encoder

(2) Spray flux nozzles

Servo spray fluxer control box

Flux tank accessories:

(2) Pressure gauges

(2) Flux filter housings

Board detect sensor

Activate flux sensor

2004 vintage.

ELECTROVERT / SPEEDLINE Vectra 450F is a powerful and reliable reflow oven designed to increase assembly throughput and improve the quality of electronic assembly products. The equipment uses advanced closed-loop temperature profiling technology and powerful forced-air convection heating to ensure accurate results. SPEEDLINE VECTRA 450/F reflow oven is a highly precise tool that can be used to solder components on printed circuit boards (PCBs), allowing for a perfectly soldered bond. The oven provides the highest levels of accuracy and consistency of any reflow oven in its class. ELECTROVERT VECTRA 450 / F features an easy-to-use control system which allows users to begin a soldering process quickly and easily. The oven can be programmed to operate on any of six pre-defined reflow profiles, or users can define their own custom profiles in order to ensure the most accurate results. Additionally, SPEEDLINE VECTRA 450 / F is designed to provide superior temperature control during the soldering process which eliminates any potential heat spike issues from occurring. In addition to providing a precise temperature profile, VECTRA 450/F is also equipped with a high-performance airflow unit. Forced air convection heats up the oven quickly, to ensure that the PCB and components reach the desired soldering temperature faster and more uniformly. This combination of rapid heating and precise temperature control allows SPEEDLINE Vectra 450F to quickly and reliably produce superior solder joints. ELECTROVERT Vectra 450F also features an audible paging machine which provides users with an alert when the oven is finished processing their component. The tool is designed for heavy-duty use, with an oversized conveyor designed to handle the most demanding throughput requirements. The advanced safety features further protect both the operator and the sensitive electronics being processed, by automatically shutting down the asset should an overheating condition occur. Overall, Vectra 450F reflow oven is the perfect choice for those who require superior accuracy and consistency during the soldering process. Combining powerful convection heating, precise temperature control, and advanced safety features, VECTRA 450 / F is the ideal choice for those who demand the very best from their reflow ovens.

There are no reviews yet