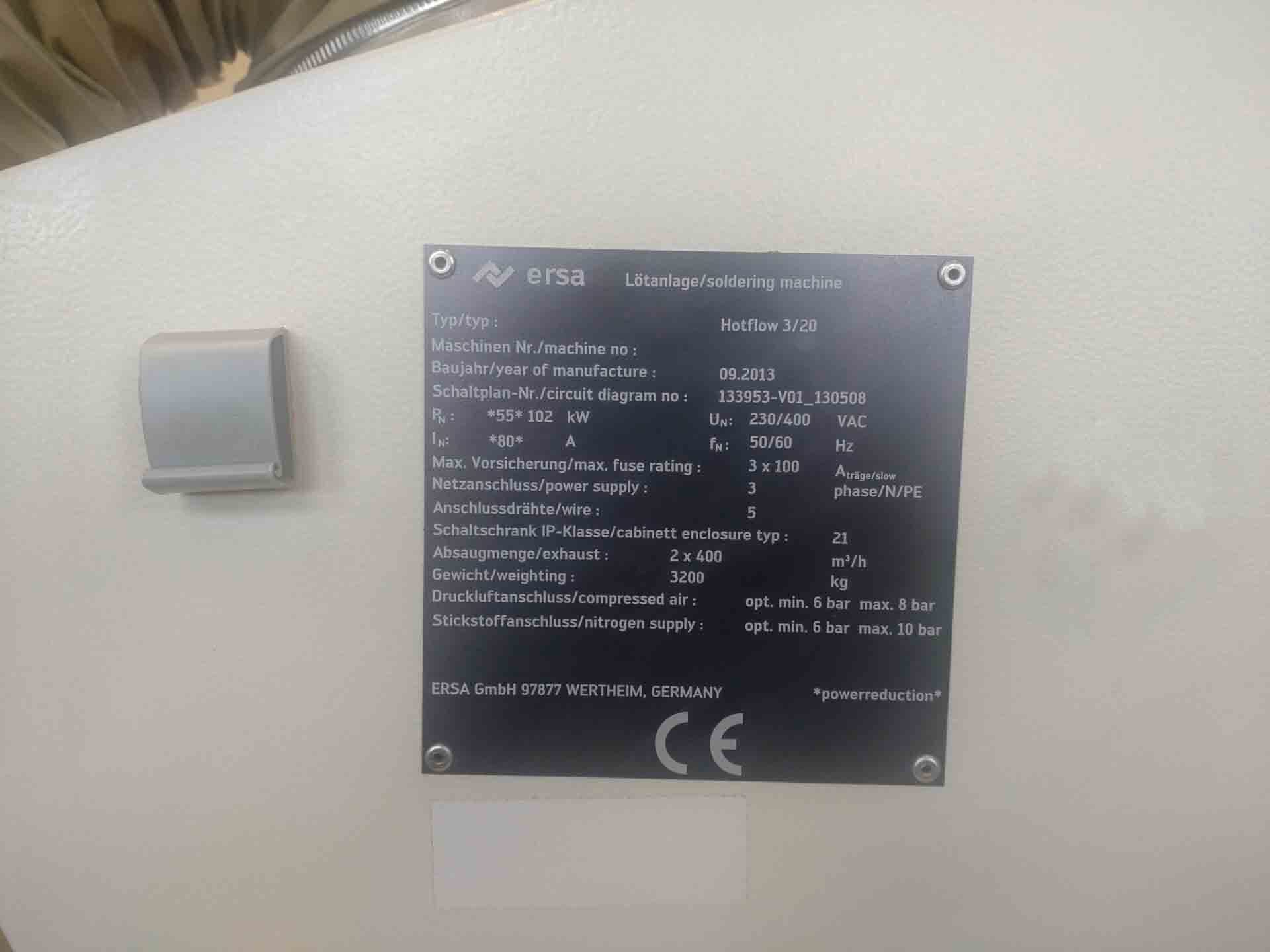

Used ERSA Hotflow 3/20 #9377007 for sale

URL successfully copied!

Tap to zoom

ID: 9377007

Vintage: 2013

Reflow oven

(10) Heating zones

PCB Support

Water cooling system

Nitrogen setup

Smema

UPS

7-top side preheating zones

3-top and bottom-side peak zones

Automatic chain lubrication

Top and bottom-side motor cooling

Safety device:

Main switch

(4) Emergency-stop buttons

(2) Exhaust monitors

Dimension:

Length: 6,590 mm

Width: 1,530 mm

Height: 1,450 – 1,580 mm

Height (open): 1,810 – 1,940 mm

Weight: 3,200 kg

Paint: RAL 7035/7016

Process zone:

Process length: 5,190 mm

Heating zone: 3,700 mm

Cooling zone: 1,490 mm

Infeed/Outfeed zone: 700 mm

Process chamber width: 770 mm

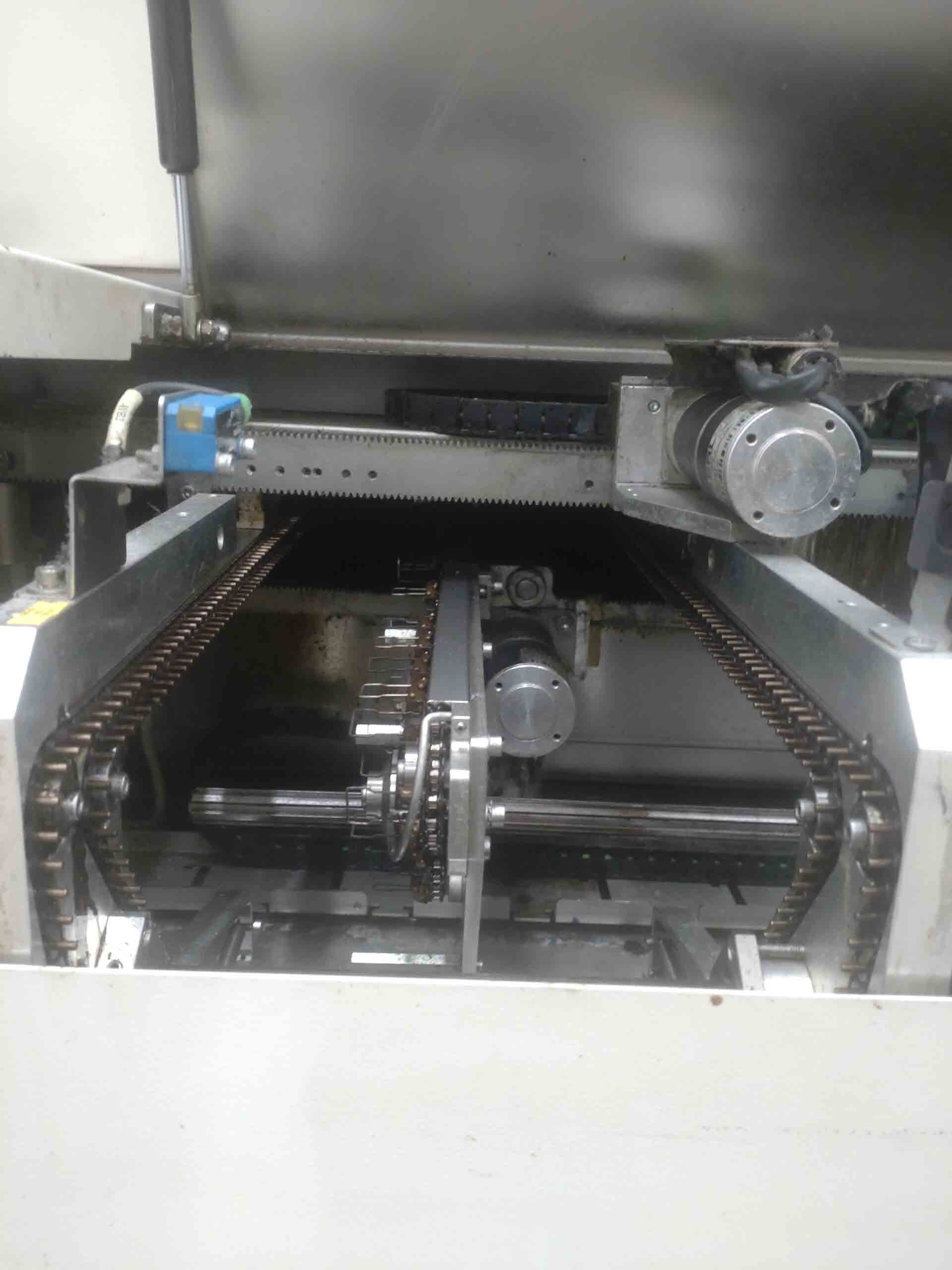

Conveyor system:

Working width: 45 – 580 mm

Working width: 45 – 580 mm (PCB center support)

Board clearance: +25/-37 mm (Standard)

Board clearance: +35/-37 mm (Option)

Center support pin height: 15 mm

Conveyor speed: 20 – 200 cm/min

Conveyor height from floor: 820 – 980 mm

Pin-and-chain conveyor: 3 mm

Edge clearance (option: 4 mm, 5 mm)

Heating system:

Convection share: 100%

Gas flow / module: approx. 500 m3/h

Convection modules: 10 top / 3 – 10 bottom

Preheating: 7 top / 7 bottom (option)

Soldering zone: 3 top / 3 bottom

Nominal rating / module: 3.3 kW

Electrical data:

Power: 5-wire-system, 3 x 400 V, N, PE

Power tolerance range: ±10 %

Frequency: 50/60 Hz

Max fuse rating: 3 x 100 A

Nominal rating: 65 kW – 104 kW

Reduced rating: 44 kW

Continuous rating for operation: 12 – 19 KW

Nitrogen option:

Gas injection: in process zone

Pressure control: 4.5 – 10 bar

Cooling:

Cooling zone: Ersa Multinet system

Coolant: water / R407C (option)

Ambient temperature: 32°C

Exhaust rating:

Exhaust stacks: 2 stacks, 150 mm, 6"

Exhaust volume per stack: 400 m3/h

Exhaust monitoring per stack: integrated

Noise level:

Permanent noise level: < 70 dB (A)

2013 vintage.

ERSA Hotflow 3/20 is a reflow oven designed for high-volume automated soldering applications. The oven is equipped with an advanced, proprietary hot flow technology that utilizes infrared absorbers to provide precise, repeatable temperature control for precision temperature ramping across the entire working zone. The Hotflow 3/20's sophisticated heat flux technology ensures uniform temperature distribution to guarantee consistently reliable manufacturing processes. Unlike traditional reflow ovens, ERSA Hotflow 3/20 requires no external thermocouples, saving setup time and eliminating potential points of failure. This self-regulating technology ensures that operators can achieve a temperature profile that's precisely tailored to their application's needs. The Hotflow 3/20's optimized components also reduce thermal stress on PCBs, leading to improved product reliability. An airlet system constantly circulates cool atmospheric air, bringing a more comfortable environment for operators and reducing the risk of errors. The Hotflow 3/20 reflow oven features a powerful heating system that boasts a heating capacity of up to 20 KW, meaning that it's capable of achieving the temperatures necessary for any soldering task. The Hotflow 3/20 also features a particularly large working zone of 1500mm x 480mm, enabling it to handle even the largest of soldering tasks without compromising uniformity or speed. Standard safety features include an enclosed, recirculated chamber, ensuring operator safety. Additionally, the Hotflow 3/20 includes an energy-saving ECO-mode that automatically monitors and adjusts the heating elements to ensure minimal energy use. The Hotflow 3/20 reflow oven is an affordable, powerful tool that's capable of consistently delivering well-soldered PCBs, even in large production runs. With a reliable heating system, a sophisticated airflow technology, and a simple interface, the Hotflow 3/20 is an ideal choice for any PCB manufacturing operation with automated soldering needs.

There are no reviews yet